Method for improving extraction rate of corn starch by virtue of extrusion and cooking

A technology of corn starch and extraction rate, which is applied in the field of extrusion cooking technology to improve the extraction rate of corn starch, can solve the problems of short-term, high-efficiency, green, and environmental protection extraction methods that have not yet been studied, high cost, and long time-consuming, etc., to achieve improvement The effect of industrial production efficiency, low production cost and short time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

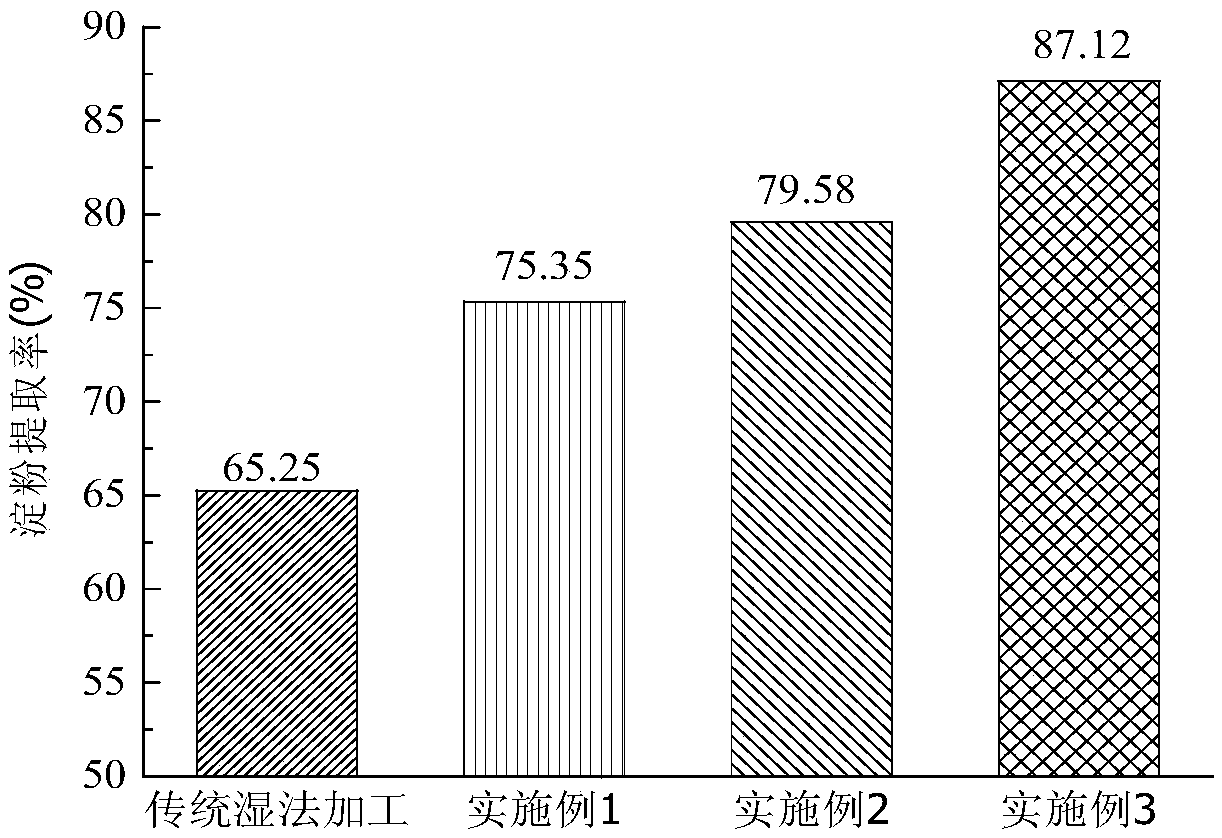

Embodiment 1

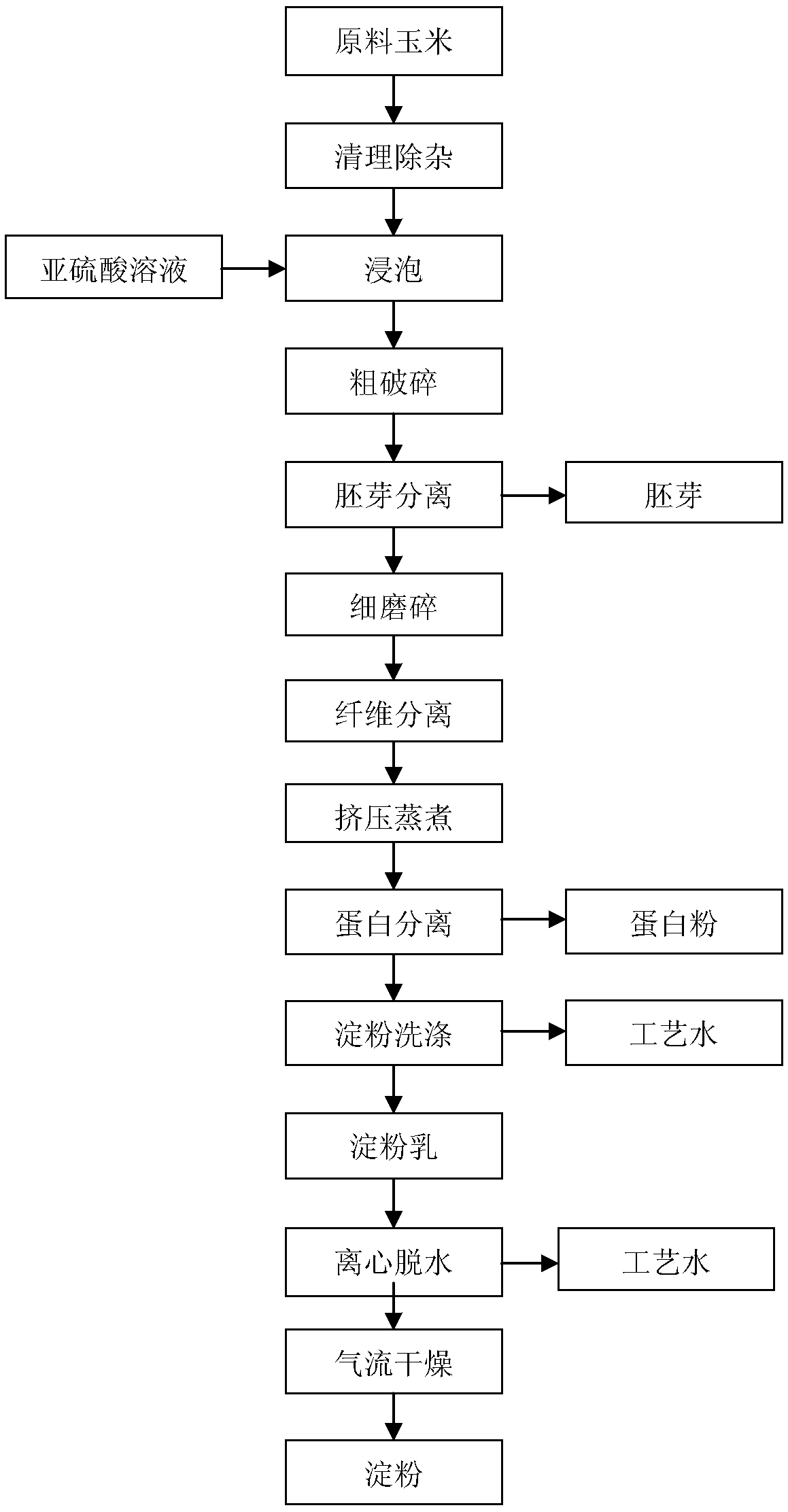

[0030] Such as figure 1 Shown is a process flow diagram of a method for improving cornstarch extraction rate by extrusion cooking of the present invention; comprises the following steps:

[0031] (1) Cleaning and removing impurities: select ordinary corn raw materials and remove straws, sandstones, metal blocks, and other debris;

[0032] (2) Soaking: take 40kg of common corn and soak for 15h in a 0.10% sulfurous acid solution at a temperature of 45°C;

[0033] (3) Coarse crushing: The soaked corn is mixed with water and crushed twice. The first crushing is to crush the corn kernels into 4-6 petals in the crusher, and after the first germ separation, it is further crushed into 8 petals. - 12 petals, from which the germ is separated again;

[0034] (4) Germ separation: The mixture of coarsely crushed water and broken corn enters the suspension separator through the feed pipe under a certain pressure, and the germ is completely separated through two suspension separators, and ...

Embodiment 2

[0041] A method for increasing the extraction rate of cornstarch by extrusion cooking:

[0042] (1) Cleaning and removing impurities: select ordinary corn raw materials and remove straws, sandstones, metal blocks, and other debris;

[0043] (2) Soaking: Take 50kg of common corn and soak it for 25h in a 0.15% sulfurous acid solution at a temperature of 50°C;

[0044] (3) Coarse crushing: The soaked corn is mixed with water and crushed twice. The first crushing is to crush the corn kernels into 4-6 petals in the crusher, and after the first germ separation, it is further crushed into 8 petals. - 12 petals, from which the germ is separated again;

[0045] (4) Germ separation: The mixture of coarsely crushed water and broken corn enters the suspension separator through the feed pipe under a certain pressure, and the germ is completely separated through two suspension separators, and the first separator feeds The consistency is 12%, the second pass is 14%. Next, the germ is sepa...

Embodiment 3

[0052] A method for increasing the extraction rate of cornstarch by extrusion cooking:

[0053] (1) Cleaning and removing impurities: select ordinary corn raw materials and remove straws, sandstones, metal blocks, and other debris;

[0054] (2) Soaking: Take 60kg of common corn and soak it for 35h in a 0.20% sulfurous acid solution at a temperature of 55°C;

[0055] (3) Coarse crushing: The soaked corn is mixed with water and crushed twice. The first crushing is to crush the corn kernels into 4-6 petals in the crusher, and after the first germ separation, it is further crushed into 8 petals. - 12 petals, from which the germ is separated again;

[0056] (4) Germ separation: The mixture of coarsely crushed water and broken corn enters the suspension separator through the feed pipe under a certain pressure, and the germ is completely separated through two suspension separators, and the first separator feeds The consistency is 12%, the second pass is 14%. Next, the germ is sepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com