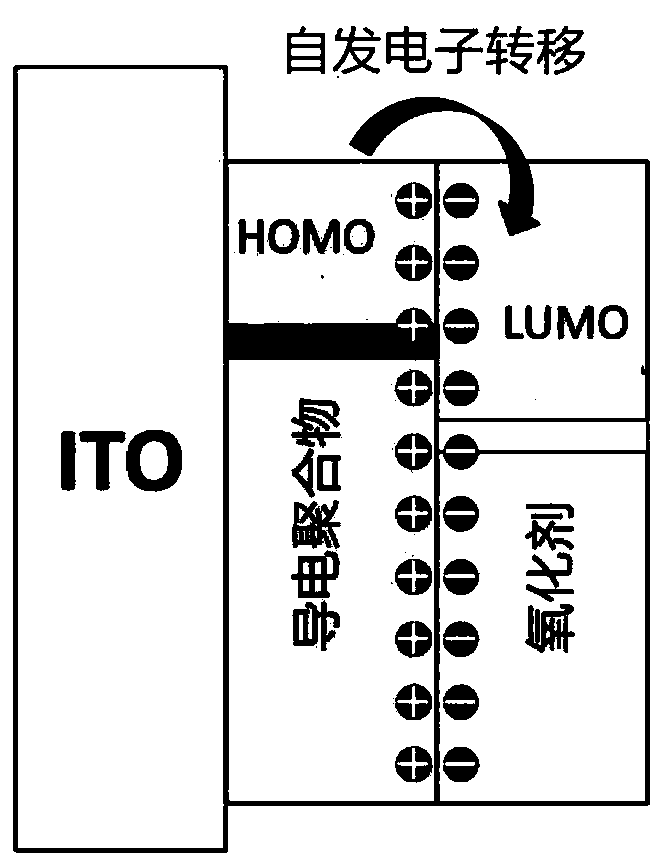

A kind of preparation method and application of organic solar cell anode dipole interface

A solar cell and organic technology, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problem of high solubility of interface materials and achieve the effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The structure of the organic solar cell device in this embodiment is ITO / anode interface / active layer / PFN-Br / Al, and the preparation steps are as follows:

[0029] After the ITO was repeatedly ultrasonically washed with acetone, ITO cleaning solution, deionized water, and isopropanol, it was dried in an oven at 80°C at a constant temperature. The ITO was then transferred into a nitrogen-protected glove box, and the conductive polymer was electrochemically polymerized using cyclic voltammetry in a three-electrode electrolytic cell system.

[0030] The specific steps of electrochemical polymerization of conductive polymers by cyclic voltammetry are as follows: EDOT is dissolved in 0.1M tetrabutylammonium hexafluorophosphate electrolyte solution, so that the concentration of EDOT is 0.1M, and cyclic voltammetry is used at 0-1.0V Scan in the range of 200mV / s, scan 5 circles, wash and dry for the anode interface of organic solar cells.

[0031] The active layer described in...

Embodiment 2

[0036] The structure of the organic solar cell device in this embodiment is ITO / anode interface / active layer / PFN-Br / Al, and the preparation steps are as follows:

[0037] After the ITO was repeatedly ultrasonically washed with acetone, ITO cleaning solution, deionized water, and isopropanol, it was dried in an oven at 80°C at a constant temperature. The ITO was then transferred into a nitrogen-protected glove box, and the conductive polymer was electrochemically polymerized using cyclic voltammetry in a three-electrode electrolytic cell system.

[0038] The specific steps of electrochemical polymerization of conductive polymers by cyclic voltammetry are as follows: EDOT is dissolved in 0.1M tetrabutylammonium hexafluorophosphate electrolyte solution, so that the concentration of EDOT is 0.1M, and cyclic voltammetry is used at 0-1.0V Scan within the range of 200mV / s, scan 5 circles, spin-coat 1mg / ml F4TCNQ solution at a speed of 3000r / min, wash and dry it, and use it on the ano...

PUM

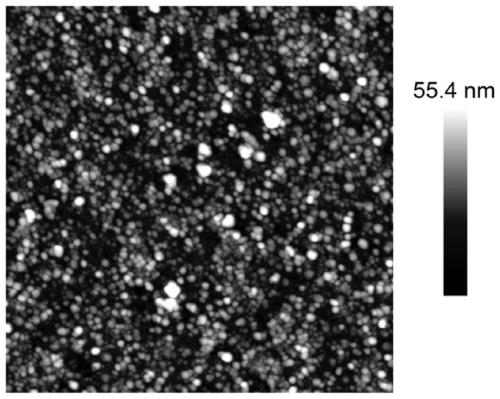

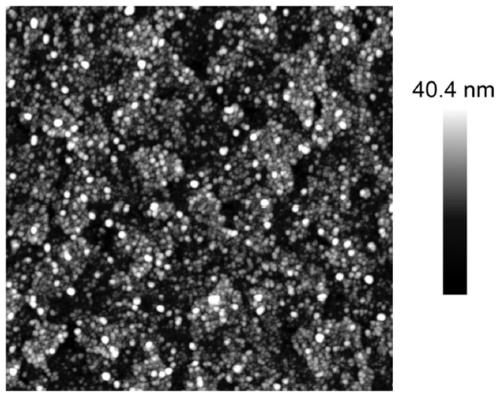

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com