Assembly, energy consumption and self-resetting method for shape memory alloy spring buckling restrained brace

A memory alloy spring, anti-buckling support technology, applied in the field of building shock absorption, can solve the problems of high replacement and maintenance costs, weak inner core support ability, no self-reset ability, etc., and achieves convenient and quick disassembly, easy maintenance, Efficient energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

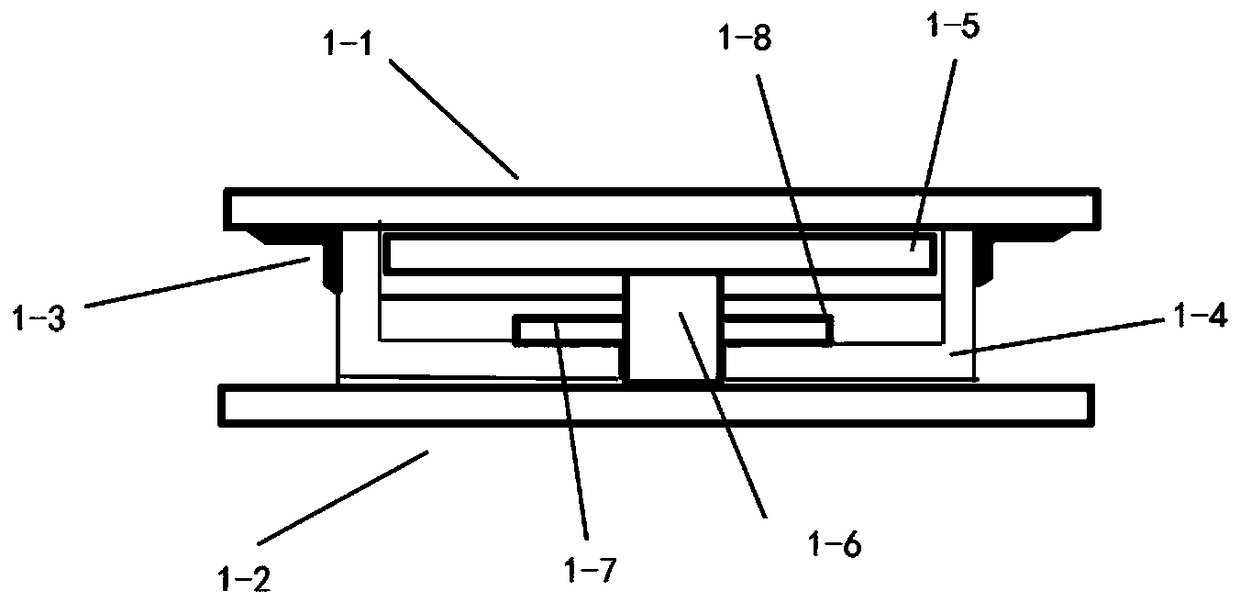

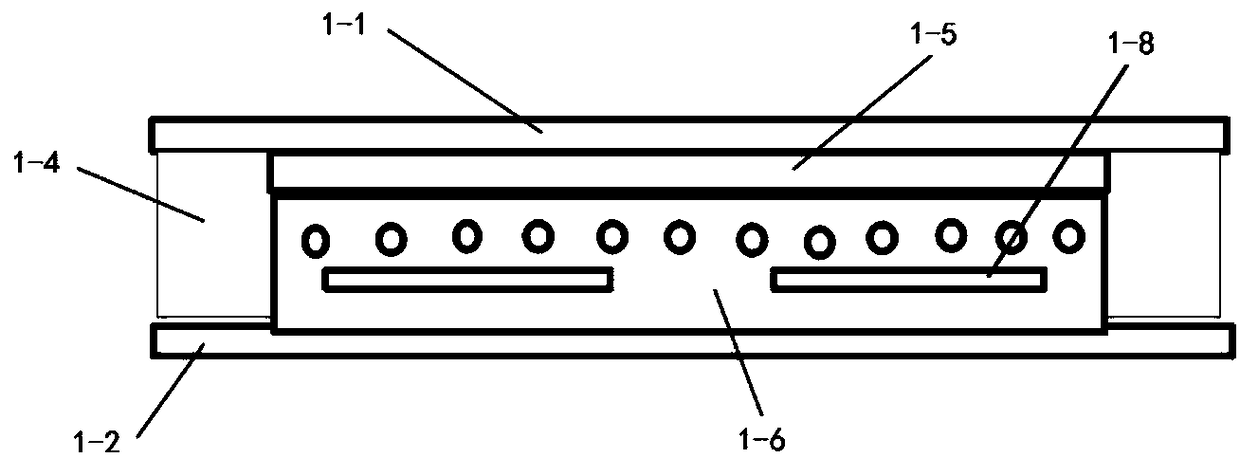

[0034] Embodiment 1: as Picture 1-1 and 1-2 As shown, a shape memory alloy strand shock absorber includes a steel plate, an L-shaped steel plate 1-4, an L-shaped connecting steel plate 1-3, a first limiting plate 1-5, a second limiting plate 1-8, Steel blocks 1-6 with cuboid holes and slots reserved, polytetrafluoroene slide plates and stranded wires 1-7 of shape memory alloy. The steel plate and the L-shaped steel plate 1-4 are connected by the L-shaped connecting steel plate 1-3, and the L-shaped connecting steel plate 1-3 is welded to the L-shaped steel plate 1-4 while being anchored to the upper steel plate 1-1 with bolts and nuts, forming The first steel plate group. One side of the steel blocks 1-6 with cuboid reserved holes and slots is welded with the steel plate, and the other side is welded with the limiting plate, and the corresponding size limiting plate is also inserted in the reserved slot to form the second steel plate group. The installation method of the sh...

Embodiment 2

[0048] Embodiment 2: as diagram 2-1 As shown, an assembled anti-buckling support uses a shape memory alloy material. The shape memory alloy has superelasticity, high damping, corrosion resistance and memory effect, so after the earthquake, the invention can reset itself, because it is assembled Therefore, it is easy to disassemble, easy for daily maintenance and post-earthquake repair. It includes an upper steel plate 2-2 with screw holes, a shape memory alloy spring 2-7, a cross-shaped long steel core with grooves 2-5, a steel plate group with screw holes 2-3, and a circular steel pipe 2- 6. Rectangular steel bar 2-4, bolt 2-1.

[0049] Further, the steel plate group 2-3 with screw holes includes a hollow rectangular body formed by a vertical plate and a bottom plate, the top surface of the vertical plate has screw holes, and the steel plate group 2-3 also includes several small U-shaped steel plate groups 2-3 percent, several small U-shaped steel plates are divided into t...

Embodiment 3

[0059] Embodiment 3: as Figure 3-1 , Figure 3-2 As shown, a ring-shaped shape memory alloy spring omnidirectional shock-isolation support includes a circular outer cylinder, a circular inner cylinder, a limit plate 3-6, an annular shape memory alloy spring 3-3, a rectangular steel plate 3-4, a circular Steel plate 3-5, circular steel plate 3-5 are used as upper connecting steel plate. The lower part of the annular shape memory alloy spring 3-3 is composed of three inner and outer cylinders 3-1. An annular shape memory alloy spring 3-3 is placed between the inner and outer cylinders 3-1, and a limit plate 3-6 is installed above to prevent the inner and outer cylinders 3-1 from breaking away. The surface of the bottom surface of the outer cylinder 3-1 is inlaid with polytetrafluoroethylene slide plates to reduce the coefficient of friction. The upper part of the shock-isolation support is composed of circular steel plates and rectangular steel plates, which are connected by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com