Method for producing functional nylon 6 alloy germanium far infrared fiber

A far-infrared fiber and production method technology, applied in the direction of fiber chemical characteristics, conductive/anti-static filament manufacturing, single-component polyamide artificial filament, etc., can solve easy agglomeration, poor uniformity, agglomeration and poor dispersion and other problems, to achieve the effect of rapid heat transfer, adjustment of physical fitness, and promotion of metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In the present embodiment, the raw material composition and production method steps of the functional nylon 6 alloy germanium far-infrared fiber are as follows:

[0031] 1. Raw material and weight:

[0032] Functional alloy germanium masterbatch 50Kg

[0033] Nylon chips 950Kg

[0034] 2. Method:

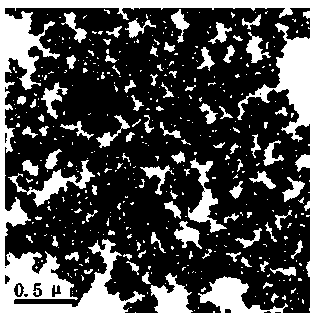

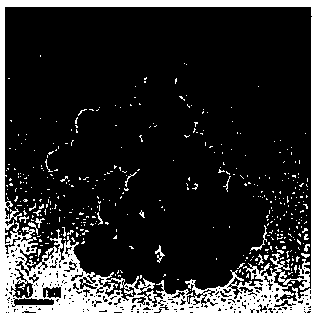

[0035] 1) Preparation of functional alloy germanium masterbatch: Grind germanium stone into micron-sized powder, about 4-5um, and then sinter at 1500°C to ash impurities and surface modification, and then grind germanium stone twice to form Nano-scale micropowder (about 50-80nm), blending nano-germanium powder and nylon 6 slices at a weight ratio of 1:4 to prepare a functional alloy germanium masterbatch; during the preparation of the masterbatch, it is necessary to strictly prevent the agglomeration of nano-germanium powder and avoid In the spinning process, the dispersion is not good, resulting in abnormal spinning and affecting production.

[0036] 2) Preparation of fu...

Embodiment 2

[0043] In the present embodiment, the raw material composition and production method steps of the functional nylon 6 alloy germanium far-infrared fiber are as follows:

[0044] 1. Raw material and weight:

[0045] Functional alloy germanium masterbatch 40Kg

[0046] Nylon chips 960Kg

[0047] 2. Method:

[0048] 1) Preparation of functional alloy germanium masterbatch: Grind germanium stone into micron-sized powder, about 4-5um, and then sinter at 1500°C to ash impurities and surface modification, and then grind germanium stone twice to form Nano-scale micropowder (about 50-80nm), blending nano-germanium powder and nylon 6 slices at a weight ratio of 1:4 to prepare a functional alloy germanium masterbatch; during the preparation of the masterbatch, it is necessary to strictly prevent the agglomeration of nano-germanium powder and avoid In the spinning process, the dispersion is not good, resulting in abnormal spinning and affecting production.

[0049] 2) Preparation of fu...

Embodiment 3

[0056] In the present embodiment, the raw material composition and production method steps of the functional nylon 6 alloy germanium far-infrared fiber are as follows:

[0057] 1. Raw material and weight:

[0058] Functional alloy germanium masterbatch 70 Kg

[0059] Nylon chips 930 Kg

[0060] 2. Method:

[0061] 1) Preparation of functional alloy germanium masterbatch: Grind germanium stone into micron-sized powder, about 4-5um, and then sinter at 1500°C to ash impurities and surface modification, and then grind germanium stone twice to form Nano-scale micropowder (about 50-80nm), blending nano-germanium powder and nylon 6 slices at a weight ratio of 1:4 to prepare a functional alloy germanium masterbatch; during the preparation of the masterbatch, it is necessary to strictly prevent the agglomeration of nano-germanium powder and avoid In the spinning process, the dispersion is not good, resulting in abnormal spinning and affecting production.

[0062] 2) Preparation of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com