A kind of grafted antibacterial polypropylene and its preparation process

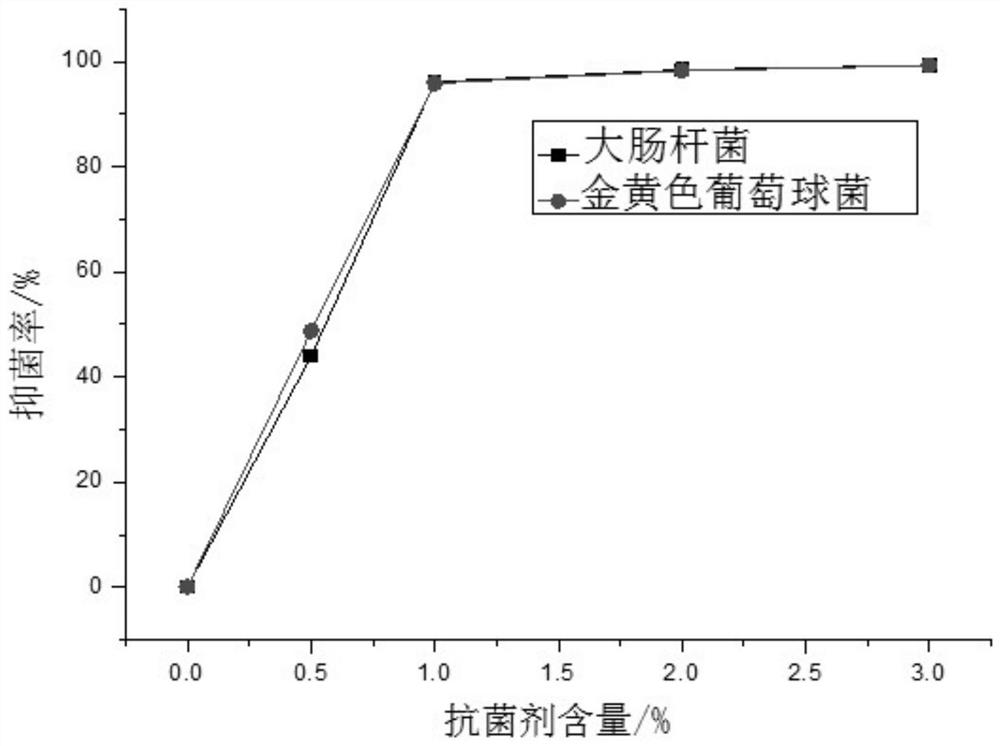

An antibacterial polypropylene and polypropylene technology, applied in the field of antibacterial polypropylene, can solve the problems of short antibacterial cycle, poor antibacterial performance of polypropylene, etc., and achieve good antibacterial durability, excellent antibacterial performance, huge market application prospects and market value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

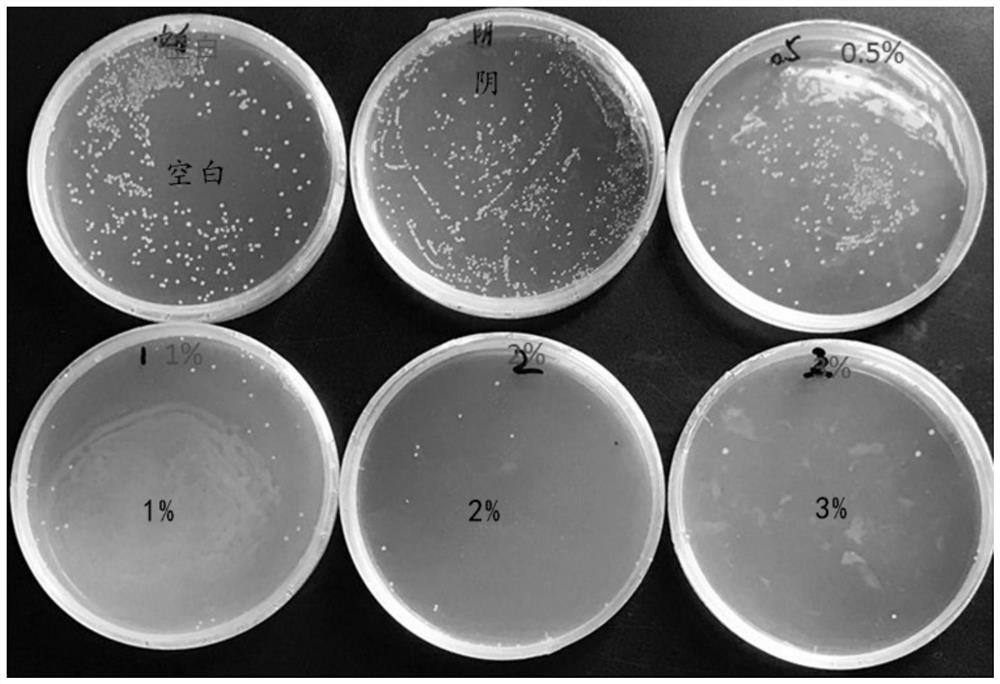

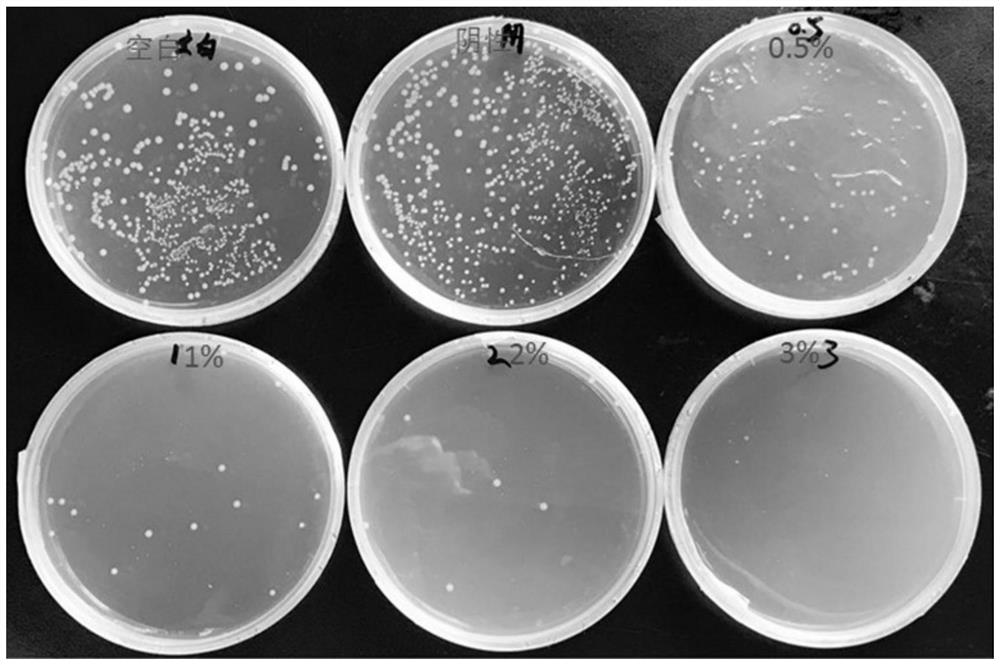

Examples

Embodiment 1

[0026] (1) Add 30g of allylbenzothiazole, 300mL of tetrahydrofuran, 12mL of liquid bromine and 0.2g of copper bromide into a 500mL three-necked flask, react at 80°C for 3 hours, and purify to obtain a light yellow solid.

[0027] (2) Add 10g of polypropylene and 100mL of dichloromethane into a 250mL three-neck flask, stir and reflux at 100°C for 3 hours. After the polypropylene was fully dissolved, 0.5 g of potassium persulfate and 12 g of maleic anhydride were added in a nitrogen atmosphere, the temperature was raised to 150° C., and the reaction was continued for 3 hours.

[0028] (3) After the temperature of the reaction liquid in (2) is cooled to 70°C, add 22g of light yellow solid, react at this temperature for 5 hours, precipitate, wash, dry and set aside.

Embodiment 2

[0030] (1) Add 32g of 5-chloro-2-methyl-4-isothiazolin-3-one, 350mL of dimethyl sulfoxide, 13mL of liquid bromine and 0.3g of copper bromide into a 500mL three-necked flask, and react at 70°C for 2 Hours, purified to a light yellow solid.

[0031] (2) Add 8g of polypropylene and 90mL of xylene into a 250mL three-necked flask, and stir and reflux at 110°C for 3 hours. After the polypropylene was fully dissolved, 0.3 g of benzoyl peroxide tert-butyl peroxide and 10 g of maleic anhydride were added in a nitrogen atmosphere, the temperature was raised to 180° C., and the reaction was continued for 4 hours.

[0032] (3) After the temperature of the reaction solution in (2) is cooled to 75°C, add 16g of light yellow solid, react at this temperature for 6 hours, precipitate, wash, dry and set aside.

Embodiment 3

[0034] (1) Add 28g of 2-octyl-4-isothiazolin-3-one, 280mL of dimethylformamide, 12mL of liquid bromine and 0.1g of copper bromide into a 500mL three-neck flask, react at 75°C for 3 hours, and purify A pale yellow solid was obtained.

[0035] (2) Add 10g of polypropylene and 120mL of pentane into a 250mL three-neck flask, stir and reflux at 120°C for 2 hours. After the polypropylene was fully dissolved, 0.6 g of dibenzoyl peroxide and 10 g of maleic anhydride were added in a nitrogen atmosphere, the temperature was raised to 160° C., and the reaction was continued for 3 hours.

[0036] (3) After the temperature of the reaction solution in (2) is cooled to 80°C, add 22g of a light yellow solid, react at this temperature for 4 hours, precipitate, wash, dry, and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com