Self-microporous high-flux nano-filtration composite membrane and preparation method thereof

A high-throughput, composite membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as self-microporous nanofiltration membranes that have not been reported

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

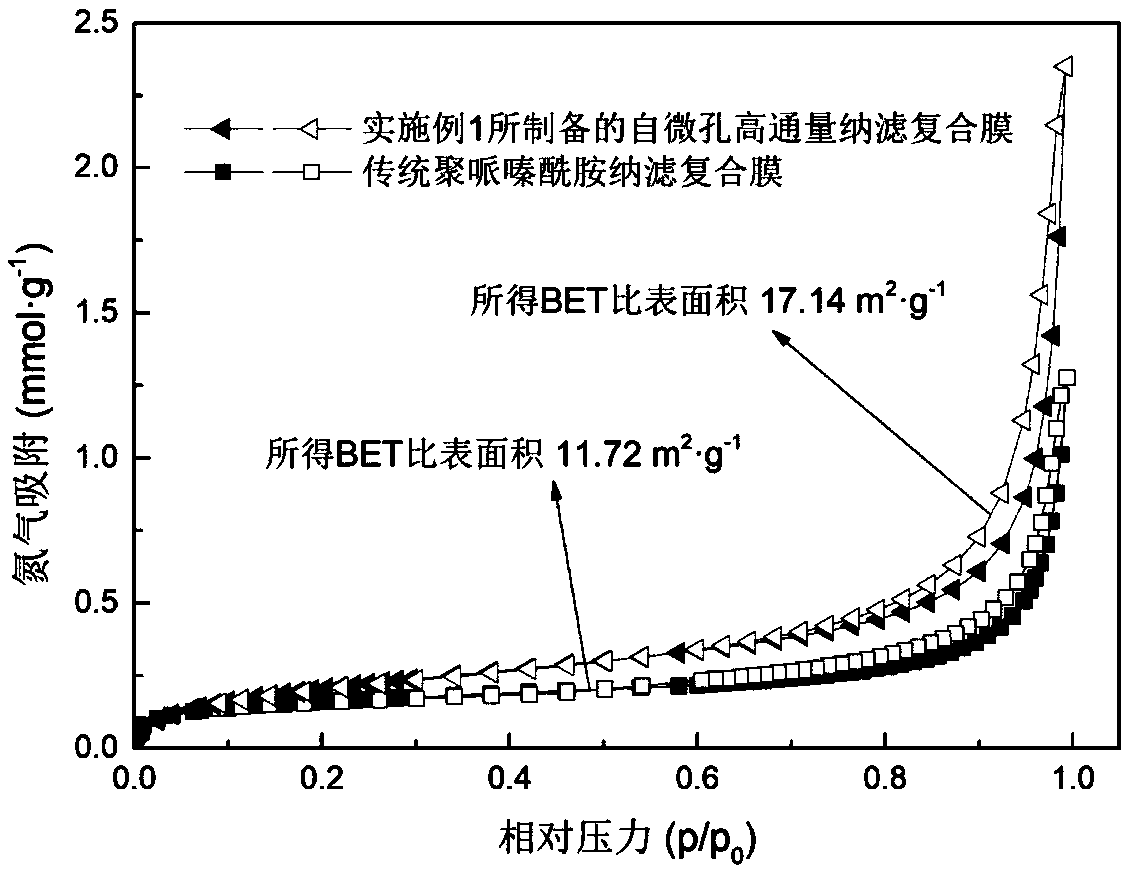

Embodiment 1

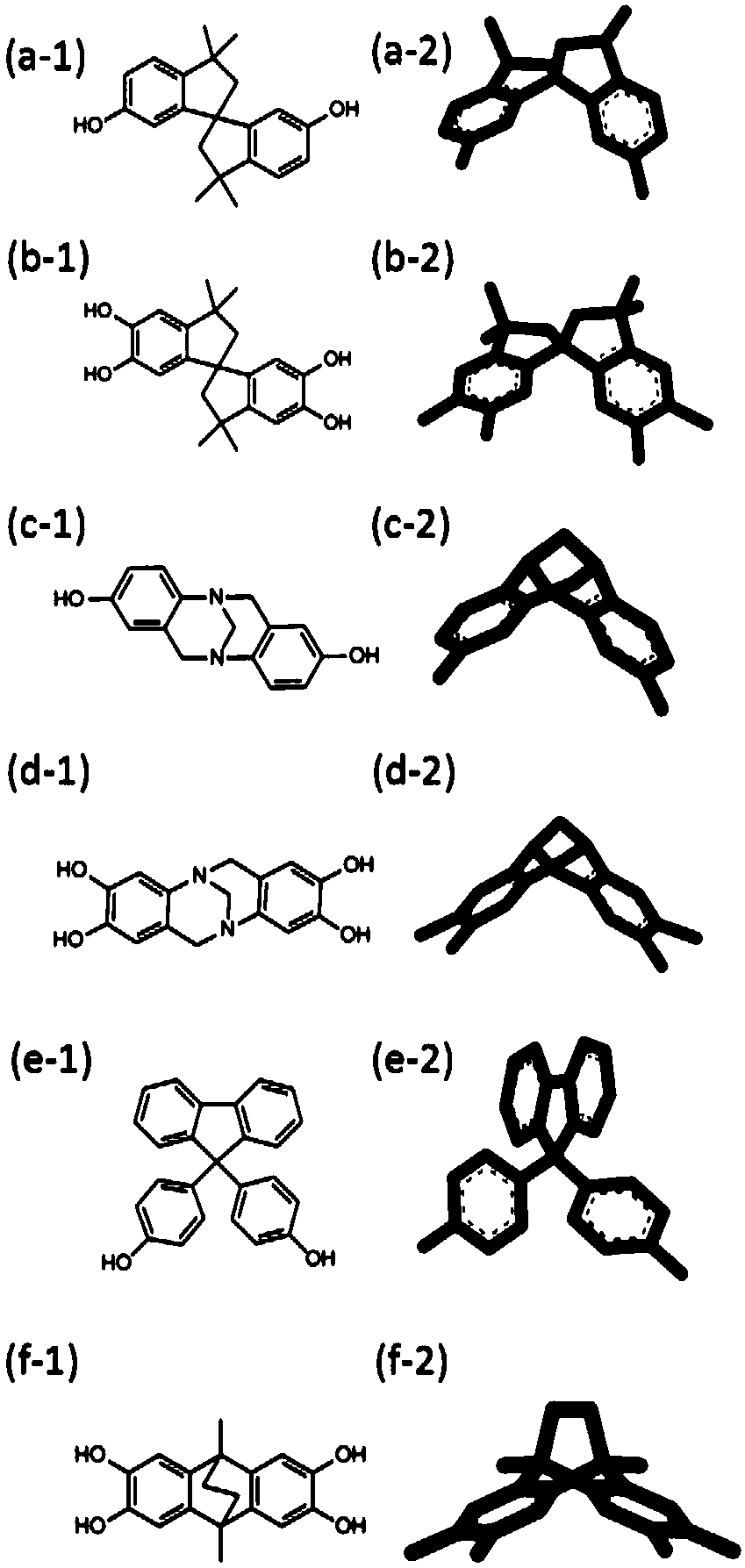

[0029] A method for preparing a self-microporous high-throughput nanofiltration composite membrane, comprising the steps of:

[0030] (1) Dissolve 6,6'-dihydroxy-3,3,3',3'-tetramethyl-1,1'-spirobisindane in NaOH aqueous solution at pH=13 to obtain a mass concentration of 1 % solution is solution one, dissolving piperazine in water to obtain a solution with a mass concentration of 1% is solution two, and the volume ratio is 1:1, and solution one and solution two are mixed to obtain a mixed solution (aqueous phase solution);

[0031] (2) Soak the polysulfone ultrafiltration membrane in the mixed solution, soak for 5 minutes, take it out, and dry the soaked polysulfone ultrafiltration membrane upper surface with an air knife;

[0032] (3) soak the upper surface of the membrane that step (2) obtains with the trimesoyl chloride n-hexane solution (oil phase solution) that contains mass concentration of 0.1%, (make the water phase solution in the polysulfone ultrafiltration membrane ...

Embodiment 2

[0040] A method for preparing a self-microporous high-throughput nanofiltration composite membrane, comprising the steps of:

[0041] (1) Dissolve 5,5’,6,6’-tetrahydroxy-3,3,3’,3’-tetramethyl-1,1’-spirobisindane in Ca(OH) at pH=9 2 In the aqueous solution, the solution with a mass concentration of 0.1% is solution one, and the solution with a mass concentration of 0.1% obtained by dissolving divinyltriamine in water is solution two. The volume ratio is 1:9, and the solution one and solution two Mix to obtain a mixed solution (water phase solution);

[0042] (2) Soak the polysulfone ultrafiltration membrane in the mixed solution, soak for 1 min, take it out, and roll the soaked polysulfone ultrafiltration membrane upper surface dry with a rubber roller;

[0043] (3) soak the upper surface of the membrane that step (2) obtains with the terephthaloyl chloride cyclohexane solution (oil phase solution) that contains mass concentration 0.01%, (make the aqueous phase solution in the p...

Embodiment 3

[0047] A method for preparing a self-microporous high-throughput nanofiltration composite membrane, comprising the steps of:

[0048] (1) Dissolve 2,8-dihydroxy-6H,12H-5,11methylenedibenzo[b,f][1,5]diazepine in KOH / NaOH (KOH The mass ratio with NaOH is 1:1) in the aqueous solution, the solution that obtains mass concentration is 5% is solution one, and 1,2-diaminocyclohexane is dissolved in water and obtains the solution that mass concentration is 5% and is solution two, According to the volume ratio of 9:1, the solution 1 and the solution 2 are mixed to obtain a mixed solution (aqueous phase solution);

[0049] (2) Soak the polyethersulfone ultrafiltration membrane in the mixed solution, soak for 60 minutes, take it out, and dry the upper surface of the soaked polyethersulfone ultrafiltration membrane with an air knife;

[0050] (3) Soak with a multifunctional organic acid chloride n-heptane solution containing a mass concentration of 1% (the multifunctional organic acid chl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com