Method for qualitatively detecting capillary cracks and segregation of steel used for piston pins

A qualitative detection and piston pin technology, applied in measuring devices, analyzing materials, testing metals, etc., can solve the problem of inability to qualitatively detect steel for piston pins, and achieve the effect of improving brand effect, accurate detection, and improving detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

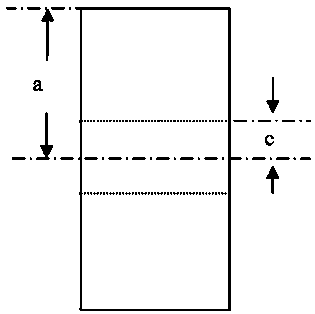

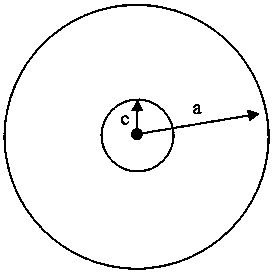

[0028] Embodiment 1: The method for qualitatively detecting hairlines and segregation of steel for piston pins is as follows.

[0029] (1) A 40Cr round steel sample is used for the piston pin, and the specification of the piston pin is φ58mm in outer diameter and φ27mm in inner diameter. According to the specification of piston pin, the specification of round steel is φ60mm. Such as Figure 4 As shown, the conventional cross-section detection method is used on the left side of the figure, and only point-like segregation can be seen in the interface, which cannot truly reflect the internal segregation of the round steel. Such as Figure 4 As shown, on the right side of the figure, the conventional longitudinal section detection method is used. Only linear segregation along the central longitudinal section can be seen in the interface, which is greatly improved compared with the cross section, but it still cannot fully reflect the internal segregation of the round steel.

[0...

Embodiment 2

[0032] Embodiment 2: The method for qualitatively detecting hairlines and segregation of steel for piston pins is as follows.

[0033]20Cr round steel for piston pins of a piston pin factory, the specifications of the piston pins are φ50mm in outer diameter and φ23mm in inner diameter. According to the specification of piston pin, the specification of round steel is φ52mm. 20Cr is low-carbon steel. According to this inspection method, the processing size: the processing radius of the first step is a=25mm, and the length is R=26mm; the processing radius of the second step is b=17.70mm, and the length is R=26mm; the third step The processing radius is c=10.35mm and the length is 2R=52mm. Detect the outer circle, middle circle and inner circle of the piston pin respectively. Such as Figure 7 , Figure 8 , Figure 9 As shown, no hairlines and black lines were found on the first and second steps, and short clusters of black lines were found on the third step (inner circle are...

Embodiment 3

[0034] Embodiment 3: The method for qualitative detection of hairlines and segregation of steel for piston pins is as follows.

[0035] 20CrH round steel sample is used for the piston pin, and the specifications of the piston pin are φ48mm in outer diameter and φ24mm in inner diameter. According to the specification of piston pin, the specification of round steel is φ50mm. Through process optimization, appropriate secondary cooling water distribution of continuous casting machine, stable process control, reduce center segregation, and improve steel quality. 20CrH is low-carbon steel. According to this inspection method, the processing size: the first step processing radius is a=24mm, the length is R=25mm; the second step processing radius is b=18mm, the length is R=25mm; the third step processing The radius is c=12mm and the length is 2R=50mm. Pickling to detect the condition of each step. Such as Figure 10 shown. No hairlines and segregation lines were found on the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com