Advanced prevention and control method for working face roof separation water disasters

A roof detachment and working face technology, applied in drainage, earthwork drilling, safety devices, etc., can solve the problems of large engineering volume and capital investment, difficulty in controlling the diversion of detachment water body, and inability to realize targeted and precise exploration and discharge. , to achieve the effect of saving the amount of engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

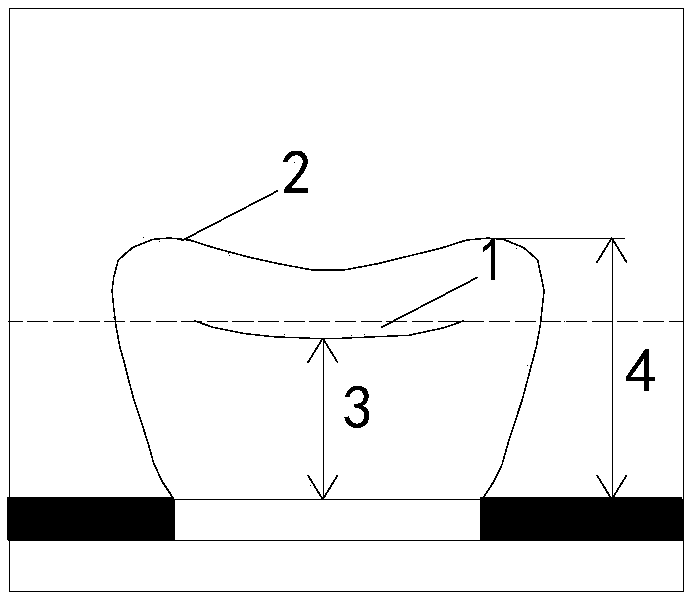

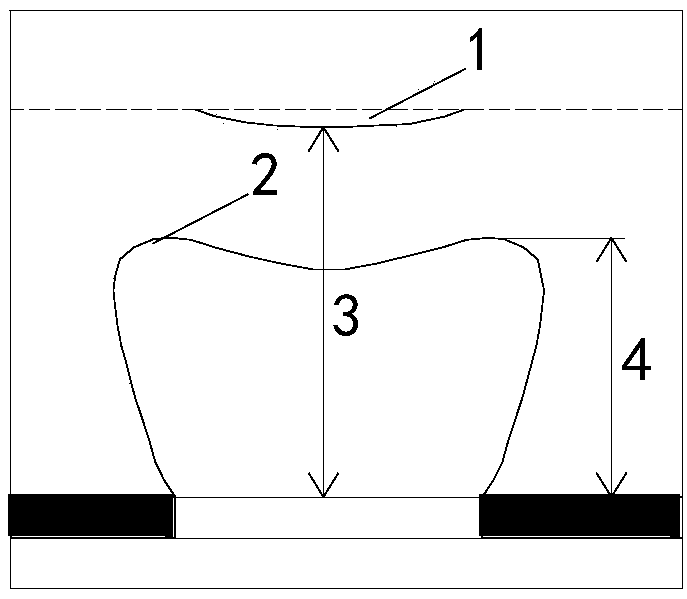

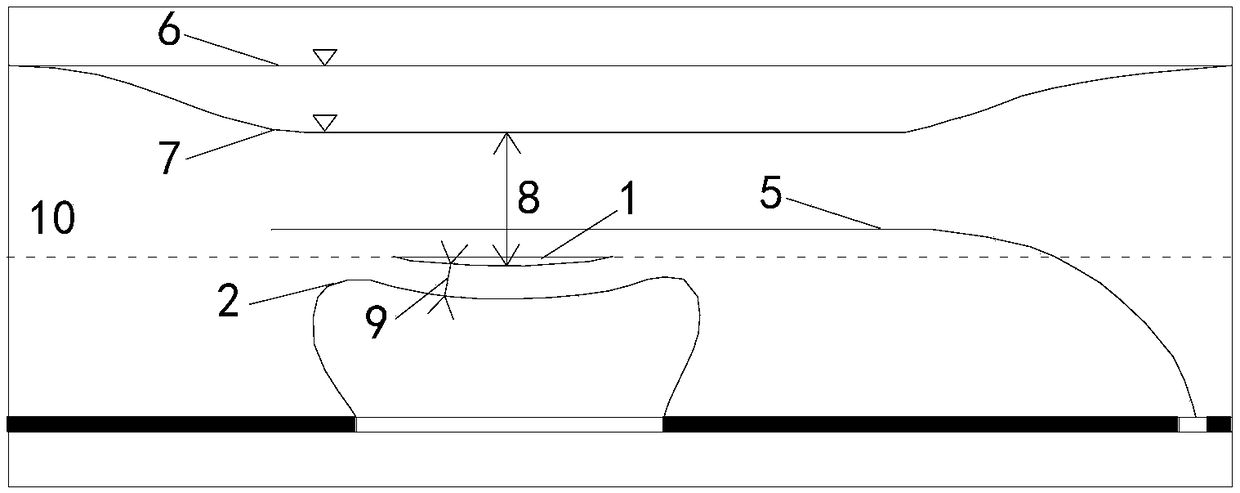

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] According to the mining conditions of the working face, the structure of the overlying rock, the hydrogeological conditions of the water-resisting layer, etc., the present invention adopts measures such as dredging and lowering the water level of the aquifer, grouting to strengthen the water-resisting layer, and exploring and releasing the separated water body to carry out comprehensive prevention and control:

[0042] First of all, long-distance directional drilling is used to drain and depressurize the water-filled aquifer in the abscission space. On the one hand, it can reduce the threat of roof water damage to the working face. Drainage efficiency; secondly, if the drainage and depressurization of the water-filled aquifer fails to achieve the expected purpose, downhole drilling can be used to grout the formed separation layer space,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com