Preparation and application of humidity visual material with aggregation-induced emission characteristic

A technology of aggregation-induced luminescence and humidity, which is applied to luminescent materials, material analysis through optical means, and analysis of materials, etc. It can solve problems such as unsuitable for naked eye observation, unsuitable for accurate measurement, and non-luminous.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The TPE-Py or TPE-VPy fluorescent molecules are first dissolved in DMSO solvent to form a 1 mg / mL mother liquor. The molecular structure of TPE-py and TPE-Vpy is shown below;

[0028]

[0029] Take the above-mentioned 16uL TPE-Py or TPE-VP solution and mix with 150mg PAA polymer, and continue to stir for 2h, where PAA is dissolved in 3mL aqueous solution to obtain TPP and TVP solutions respectively;

[0030] Preparation of TPP and TVP films: spin-coated the above solution on the surface of quartz glass to obtain a humidity sensing film;

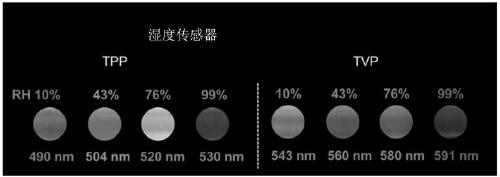

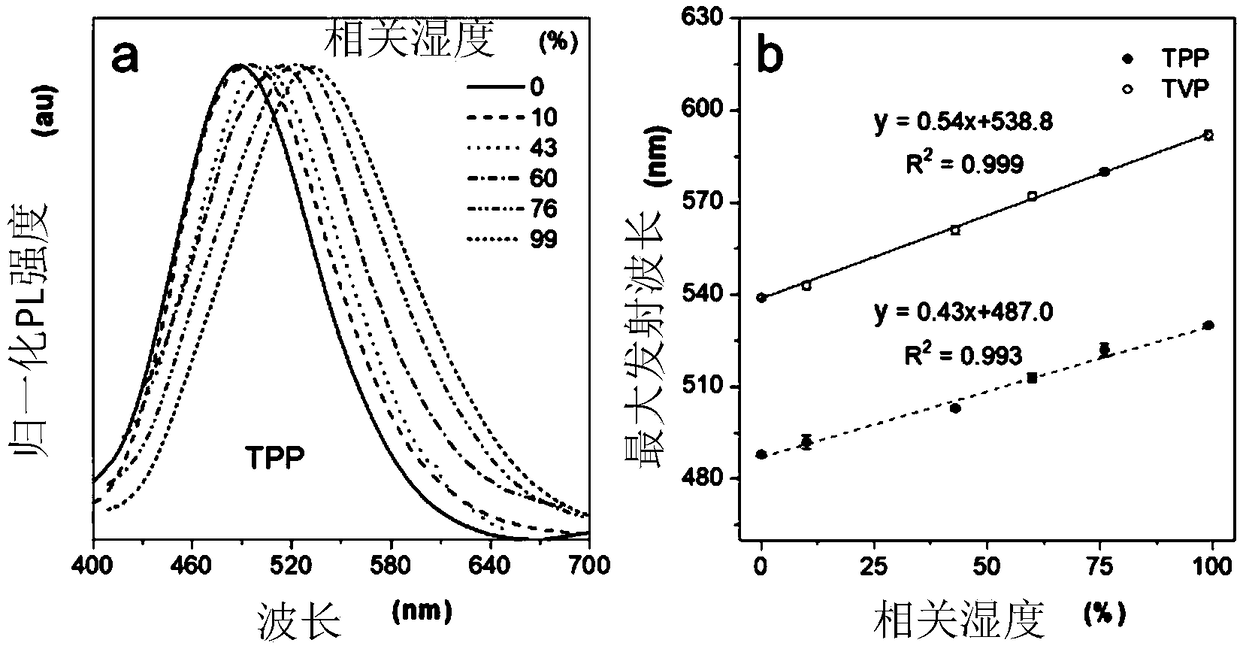

[0031] The obtained film was verified, the film was placed in a self-made humidity control box, and the above two materials were observed with the naked eye. It was found that under the excitation of the ultraviolet spectrum, the luminescence color of TPP and TVP materials under different humidity conditions occurred. Obvious redshift, such as figure 1 Shown. Furthermore, fluorescence spectroscopy is used to characterize the above films unde...

Embodiment 2

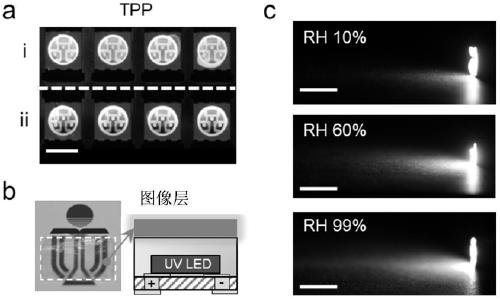

[0033] The AIE sensor with moisture-sensitive fluorescence luminescence characteristics provides a visual way to quantify the RH in a sealed package. by image 3 The package performance of the LED chip shown in a is proved. The surface of the LED chip is coated with TPP, and then the upper layer is encapsulated with silicone resin (PDMS). The organic silicon packaging system blocks the entry of water vapor in the surrounding area, and the fluorescent color of TPP has not changed. However, for the unencapsulated LED chips, the TPP emits red shift. In addition, inspired by traffic lights, a smart humidity LED light based on AIE sensors was demonstrated. Prepare transparent and flexible TPP film by drip coating method, and then integrate it into UV LED, such as image 3 Shown in b. When the ambient humidity increases ( image 3 c), the fluorescent color will automatically change from blue to green, and then to orange, and dynamic color feedback of relative humidity in a relative...

Embodiment 3

[0035] The water vapor is confined in the capillary, and its diffusion process is monitored to verify the ability of the AIE sensor to achieve high-resolution humidity change measurement in space. The present invention uses TPP aqueous solution to fill the glass capillary: first, the glass capillary is heated at 100°C to ensure complete removal of water. During the evaporation of water, TPP forms a uniform film on the inner surface of the glass capillary ( Figure 4 a). Fluorescence microscope observation shows that the thickness of the TPP film is about 16 μm. And the film emits green fluorescence, corresponding to an environmental RH value of 60%. A small amount of water is added to one end of the prepared capillary by capillary action. When heated, water vapor is generated and gradually diffuses into the capillary to form a humidity gradient distribution ( Figure 4 b). Through the use of Matlab for processing, the accurate determination of the RH value corresponding to ea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com