A kind of modified attapulgite, preparation method and application in low-smoke halogen-free flame retardant cable

A technology of attapulgite and flame retardant cable material, which is applied in the field of flame retardant materials and can solve the problem that the cable cannot be guaranteed not to fire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

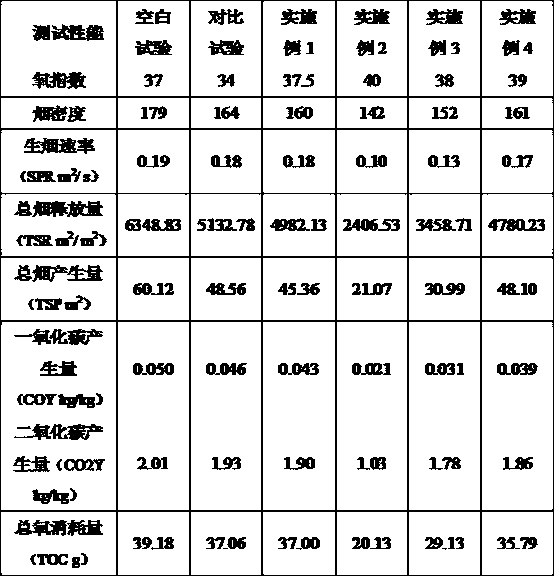

Embodiment 1

[0025] Preparation of modified attapulgite: calcinate attapulgite at 300-350°C for 5 hours, and cool to room temperature naturally in a closed state to prevent secondary water absorption; according to the mass concentration of 30%-50%, the calcined attapulgite Configured as a tetrahydrofuran solution, the system as a whole was degassed 10 times, and then protected by nitrogen; 0.5M trimethylsilylacetylene lithium tetrahydrofuran solution was added to the above system, and the amount of trimethylsilylacetylene lithium was the mass fraction of attapulgite 0.5%, reflux reaction at 80°C for 5h; after the reaction was completed, remove tetrahydrofuran by distillation under reduced pressure, vacuum dry at 100°C for 12h, and transfer the dried modified attapulgite powder to a high-speed pulverizer in a nitrogen atmosphere without air contact , crushed to 2000~2500 mesh.

[0026] Preparation of pellets: The modified attapulgite and EVA prepared above were blended at a high speed at a ...

Embodiment 2

[0028] The difference from Example 1 is that the amount of lithium trimethylsilylacetylene is 5% of the mass fraction of attapulgite.

Embodiment 3

[0030] The difference from Example 1 is that the amount of lithium trimethylsilylacetylene is 7% of the mass fraction of attapulgite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com