Preparation method of high-performance water-permeation-resistant material

A high-performance, water infiltration technology, used in the field of waterproof infiltration material preparation, can solve the problems of short life, easy aging, toxicity, etc., and achieve the effect of long waterproof effective time, high resistance to water infiltration, non-toxic and harmless use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

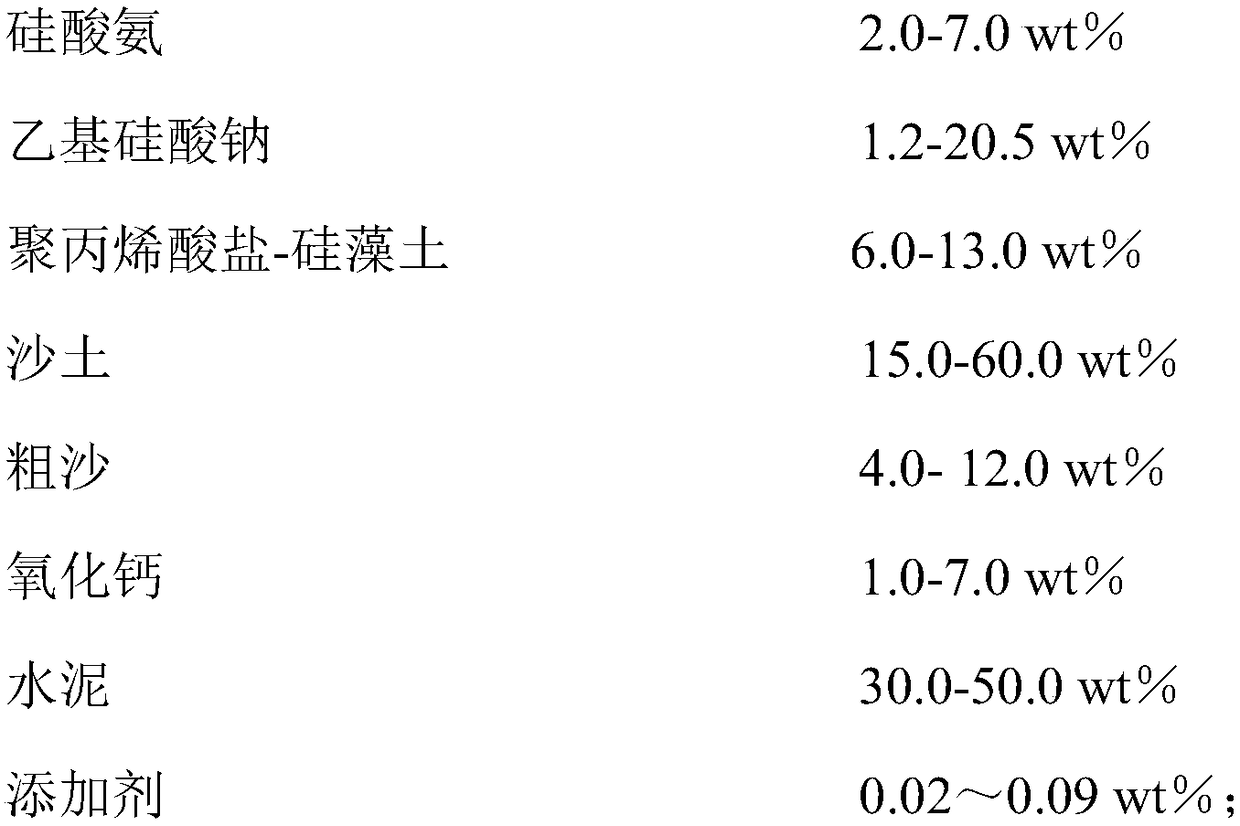

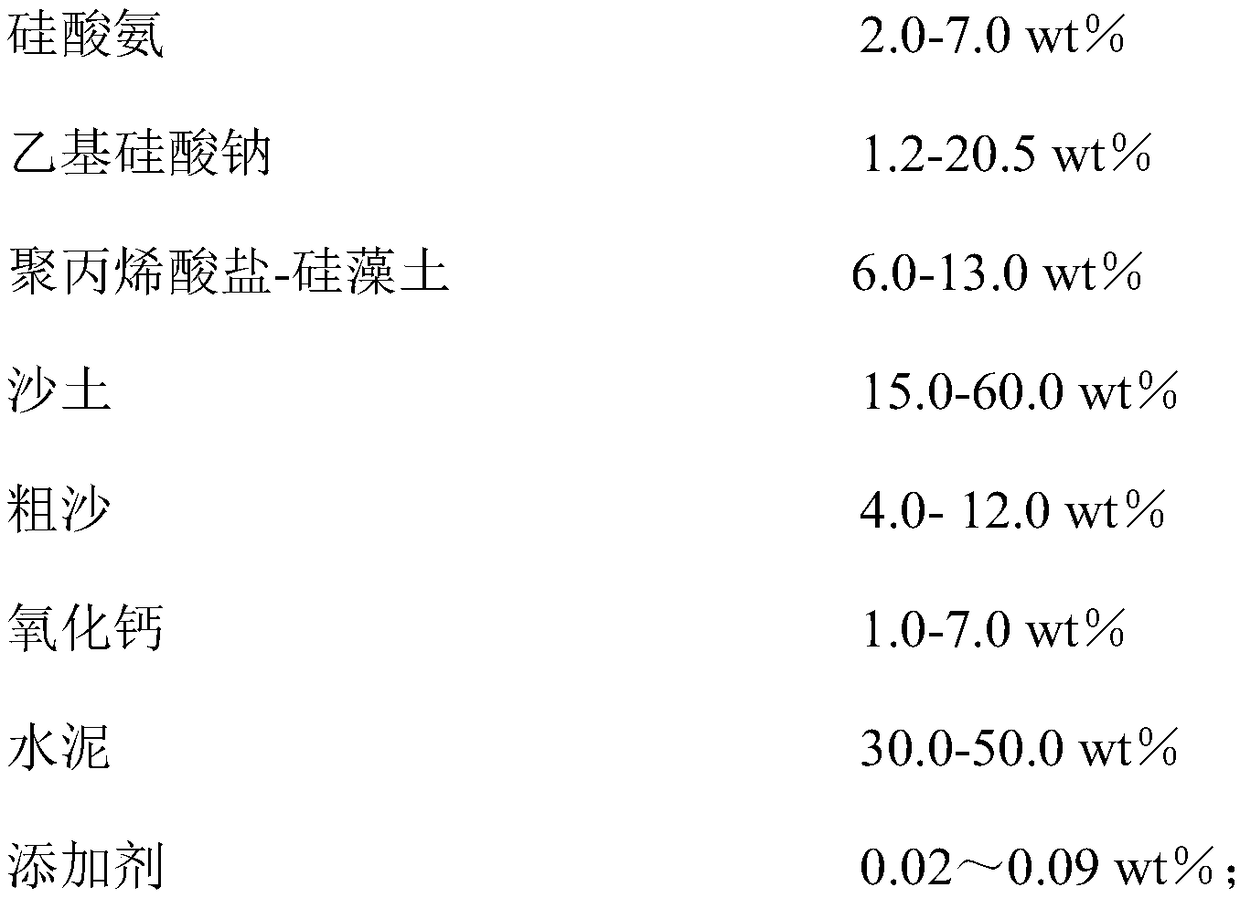

Method used

Image

Examples

Embodiment 1

[0016] First, add 1Kg of ammonium silicate and 6Kg of ethyl sodium silicate into the container, then add 1Kg of water and stir well to make it evenly mixed, then add sodium polyacrylate-diatomaceous earth 10Kg, 100 mesh sand 26Kg, 10 mesh 6Kg of coarse sand, 1Kg of calcium oxide, 49Kg of Portland cement and 0.03Kg of additives are mixed thoroughly to prepare a high-performance water-resistant material. During construction, the water-resistant infiltration material is mixed with water (the mass ratio of waterproof infiltration material to water is 2:1), stirred evenly, and spread on the roof or the ground with a thickness of 2-8cm.

Embodiment 2

[0018] First, add 3Kg of ammonium silicate and 5Kg of sodium ethyl silicate into the container, then add 1Kg of water and stir well to make it evenly mixed, then add sodium polyacrylate-diatomaceous earth 8Kg, 120 mesh sand 30Kg, 20 mesh 4Kg of coarse sand, 2Kg of calcium oxide, 47Kg of Portland cement and 0.05Kg of additives are mixed thoroughly to prepare a high-performance anti-water infiltration material. During construction, the water-resistant infiltration material is mixed with water (the mass ratio of waterproof infiltration material to water is 2:1), stirred evenly, and spread on the roof or the ground with a thickness of 2-8cm.

Embodiment 3

[0020] First, add 5Kg of ammonium silicate and 4Kg of ethyl sodium silicate into the container, then add 1Kg of water and stir well to make it evenly mixed, then add sodium polyacrylate-diatomite 6Kg, 150 mesh sand 30Kg, 40 mesh 7Kg of coarse sand, 3Kg of calcium oxide, 44Kg of Portland cement and 0.08Kg of additives are mixed thoroughly to prepare a high-performance water-resistant material. During construction, the water-resistant infiltration material is mixed with water (the mass ratio of waterproof infiltration material to water is 2:1), stirred evenly, and spread on the roof or the ground with a thickness of 2-8cm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com