Heat conduction limiting type adhesive smearing device

An adhesive and limit protrusion technology is applied in the field of thermally conductive limit type adhesive applicator, which can solve the problems of waste of raw materials, adhesive hardening, uneven application, etc., and achieves the effect of light structure design, ingenious structure design, and avoiding material spillage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The content of the present invention will be further described in detail below in conjunction with the accompanying drawings.

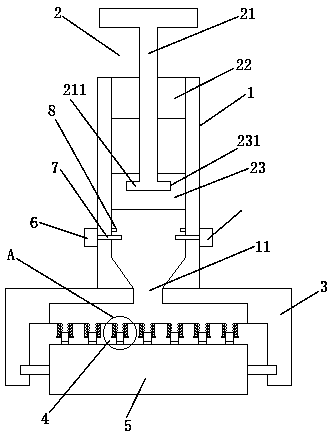

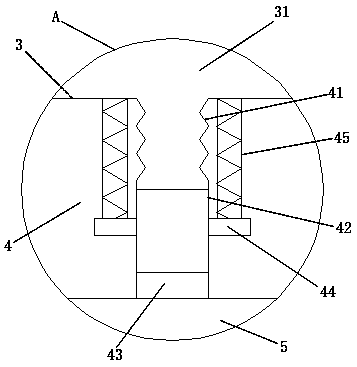

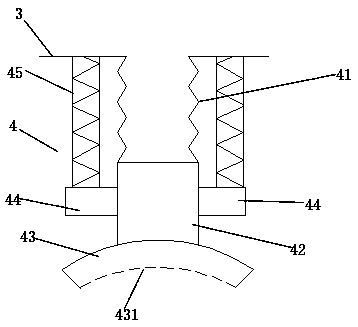

[0018] Such as Figures 1 to 3 As shown, a heat-conducting position-limiting adhesive application device includes an upper tube body 1, a lower connecting frame 3, a driving mechanism 2, a discharge mechanism 4, a coating roller 5, a heat-conducting rod 7, a heating mechanism 6, and a position-limiting protrusion 8. The upper pipe body 1 is distributed up and down, the upper end of the upper pipe body 1 is open at both ends, and the upper pipe body 1 is provided with a material storage chamber inside; the driving mechanism 2 includes a driving screw 21, a positioning block 22, a telescopic piston 23; the positioning block 22 is closed and installed on the inner upper end of the upper pipe body 1; the driving screw 21 is threaded on the positioning block 22; the telescopic piston 23 is installed in the storage chamber of the upper pipe body 1 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com