Flexible composite electrode material, a preparation method and an application thereof

A composite electrode and flexible technology, which is applied in the field of flexible composite electrode materials and its preparation, can solve the problems of poor conductivity, conductive agents and adhesives reduce the specific capacity of electrodes, and achieve improved stability, light weight, and low preparation costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

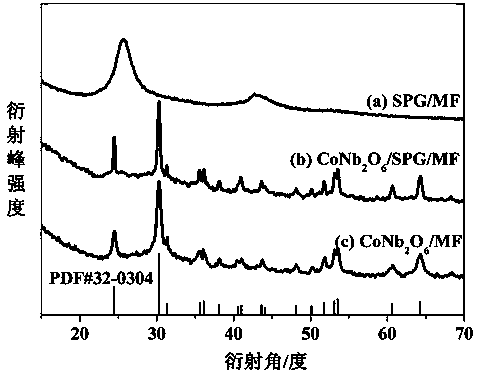

[0037] (1) Mix 50 mg graphene oxide, 2 mL concentrated H 2 SO 4 (mass concentration 95-98%) and 2 mL phytic acid (mass concentration ≥ 70%) were uniformly mixed in 56 mL aqueous solution, and ultrasonically dispersed for 2 h to obtain uniformly mixed mixture A;

[0038] (2) Transfer the mixed liquid A to the polytetrafluoroethylene liner of the hydrothermal kettle, and conduct a hydrothermal reaction at 160°C for 12 hours to obtain a black suspension, which is filtered, washed, and dried in a vacuum oven at 65°C to obtain sulfur Phosphorus-doped graphene;

[0039] (3) Mix 0.004 mol of anhydrous niobium pentoxide with 5 mL of hydrofluoric acid (mass concentration: 40%), add 55 mL of deionized water, transfer to a polytetrafluoroethylene lining of a hydrothermal kettle, and heat at 120 °C The reaction was carried out at lower temperature for 10 h, cooled to room temperature, and the reaction liquid B was obtained;

[0040] (4) Add 0.02mol of ammonium oxalate, 50mg of sulfur-p...

Embodiment 2

[0051] (1) Mix 50 mg graphene oxide, 1 mL concentrated H 2 SO 4 (mass concentration 95-98%), 1 mL phytic acid (mass concentration ≥ 70%) were uniformly mixed in 58 mL aqueous solution, and ultrasonically dispersed for 2 h to obtain a uniformly mixed mixture A;

[0052] (2) Transfer the mixed liquid A to the polytetrafluoroethylene liner of the hydrothermal kettle, and conduct a hydrothermal reaction at 170°C for 10 hours to obtain a black suspension, which is filtered, washed, and dried in a vacuum oven at 60°C to obtain sulfur Phosphorus-doped graphene;

[0053] (3) Mix 0.004 mol of anhydrous niobium pentoxide with 6 mL of hydrofluoric acid (mass concentration: 40%), add 54 mL of deionized water, transfer to a polytetrafluoroethylene lining of a hydrothermal kettle, and heat at 150 °C Under reaction 6h, be cooled to room temperature, obtain reaction solution B;

[0054] (4) Add 0.02 mol of ammonium oxalate, 50 mg of graphene and 0.004 mol of cobalt nitrate into 60 mL of re...

Embodiment 3

[0059] (1) Mix 50 mg graphene oxide, 3 mL H 2 SO 4 (mass concentration 95-98%) and 3 mL phytic acid (mass concentration ≥ 70%) were uniformly mixed in 54 mL aqueous solution, and ultrasonically dispersed for 2 h to obtain uniformly mixed mixture A;

[0060] (2) Transfer the mixed solution A to the polytetrafluoroethylene lining of a hydrothermal kettle, and react with it at 150°C for 8 hours to obtain a black suspension, which is filtered, washed, and dried in a vacuum oven at 65°C to obtain sulfur Phosphorus-doped graphene;

[0061] (3) Mix 0.006 mol of anhydrous niobium pentoxide with 8 mL of hydrofluoric acid (mass concentration: 40%), add 52 mL of deionized water, transfer to a polytetrafluoroethylene lining of a hydrothermal kettle, and heat at 100 °C The reaction was carried out for 12 h, cooled to room temperature, and the reaction solution B was obtained;

[0062] (4) Add 0.03 mol of ammonium oxalate, 50 mg of graphene and 0.003 mol of cobalt nitrate in step (2) to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com