Method and system for measuring temperature of circuit coolant

A coolant temperature, coolant technology, applied in the direction of reducing greenhouse gases, climate sustainability, reactors, etc., can solve the problems of insufficient insertion depth of thermal resistance thermometers, cylinder wall thickness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following descriptions of various embodiments refer to the accompanying drawings to illustrate specific embodiments in which the present invention can be implemented.

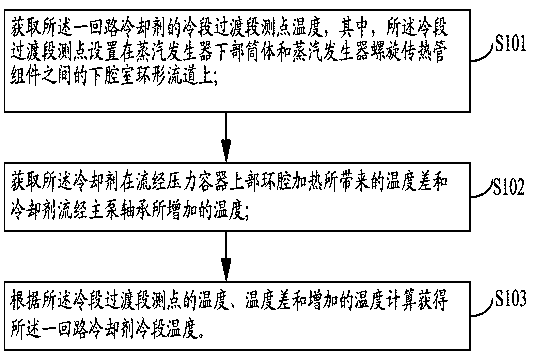

[0040] refer to figure 1 As shown, Embodiment 1 of the present invention provides a method for measuring the temperature of the cold section of a coolant in a primary circuit, including the following steps:

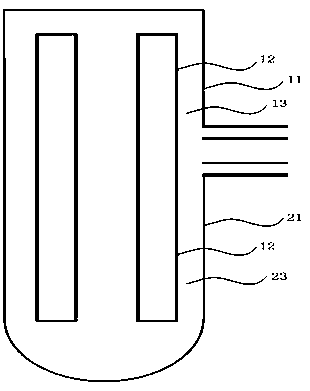

[0041] Step S101. Obtain the temperature of the measuring point in the transition section of the cold section of the primary circuit coolant, wherein the measuring point in the transition section of the cold section is set at the lower part between the lower cylinder of the steam generator and the spiral heat transfer tube assembly of the steam generator. On the annular flow channel of the chamber.

[0042] Step S102, obtaining the temperature difference caused by the coolant flowing through the upper annular cavity of the pressure vessel and the temperature increase caused by the coolant flow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com