Film thickness sample, inspection sample and inspection method for calibrating ellipsometer

An inspection method and ellipsometer technology, which is applied in the field of ellipsometer calibration, can solve problems such as deviations in results, and achieve the effects of consistent thickness, improved accuracy, and consistent regions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention. Based on the embodiments of the present invention, any modifications, equivalent replacements and improvements within the spirit and principles of the present invention made by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

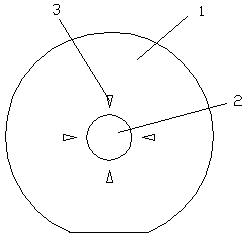

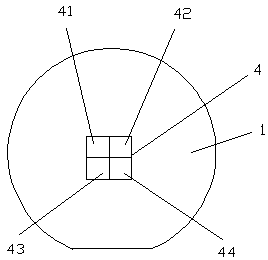

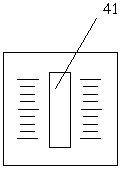

[0026] The film thickness samples for calibrating the ellipsometer are a series of film thickness samples with different film thicknesses. Silicon wafer 1 is selected as the substrate material, and each sample is a silicon wafer 1 with a thin film attached. The thin film is divided into two types, namely Silicon film and silicon nitride film; including the two most commonly used m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com