Self-repairing reinforcing material for optical cable, and preparation method thereof

A reinforced material and self-repairing technology, which is applied in the field of optical cables and optical cable materials, can solve the problems of increasing the cost and waste of resources in the communication operation industry, affecting the service life of optical cables, and not being able to achieve self-repairing, etc., so as to improve self-healing and self-repairing effect, the effect of improving self-healing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

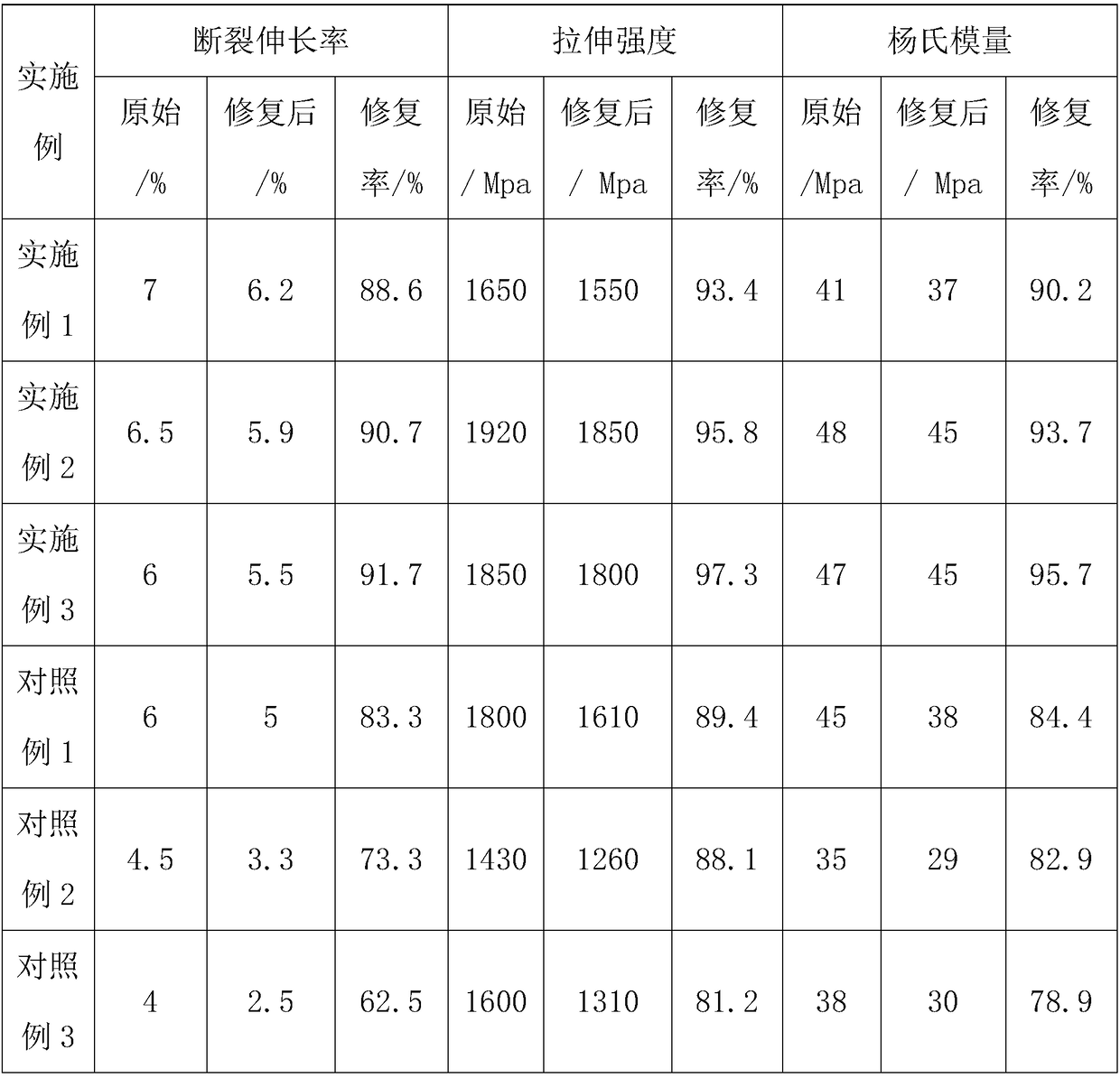

Examples

Embodiment 1

[0017] A self-repairing reinforcing material for an optical cable, comprising a base material and a resin layer on the surface of the base material, the base material is glass fiber, and the raw materials of the resin layer include by weight: 80 parts of epoxy resin, 20 parts of amide oligomer, 30 parts of self- Restorative polyurethane, 1 part zinc stearate;

[0018] Among them, the preparation process of the amide oligomer includes: heating the dimer acid and diethylenetriamine to 90° C. for 3 hours under the protection of nitrogen atmosphere, and continuing the reaction for 1 hour under vacuum to obtain the amide oligomer; The molar ratio of diethylenetriamine is 1:1, and the dimer acid ratio is a mixture of 70wt% dibasic acid and 30wt% tribasic acid;

[0019] The preparation process of self-healing polyurethane is as follows: heat polyether polyol to 100°C for vacuum dehydration, then cool down to 70°C, add toluene diisocyanate dropwise, react for 3 hours, cool down to 0°C...

Embodiment 2

[0022] A self-repairing reinforcing material for an optical cable, comprising a base material and a resin layer on the surface of the base material, the base material is a mixture of aramid fibers and basalt fibers, and the raw materials of the resin layer include by weight: 100 parts of epoxy resin, 10 parts of amide low polymer, 40 parts self-healing polyurethane, 2 parts zinc stearate;

[0023] Among them, the preparation process of the amide oligomer includes: heating the dimer acid and diethylenetriamine under the protection of nitrogen atmosphere to 100 ° C for 2 hours, and then vacuumizing and continuing the reaction for 2 hours to obtain the amide oligomer; The molar ratio of diethylenetriamine is 1.5:1, and the dimer acid ratio is a mixture of 90wt% dibasic acid and 10wt% tribasic acid;

[0024] The preparation process of self-healing polyurethane is as follows: heat up polyether polyol to 120°C for vacuum dehydration, then cool down to 80°C, add toluene diisocyanate ...

Embodiment 3

[0027] A self-repairing reinforcing material for an optical cable, comprising a base material and a resin layer on the surface of the base material, the base material is aramid fiber, and the raw materials of the resin layer include by weight: 90 parts of epoxy resin, 15 parts of amide oligomer, 35 parts Self-healing polyurethane, 1.5 parts organotin;

[0028] Among them, the preparation process of the amide oligomer includes: heating the dimer acid and diethylenetriamine to 95° C. for 2.5 hours under the protection of nitrogen atmosphere, and continuing the reaction for 1.5 hours under vacuum to obtain the amide oligomer; The molar ratio of acid to diethylenetriamine is 1.2:1, and the dimer acid ratio is a mixture of 80wt% dibasic acid and 20wt% tribasic acid;

[0029] The preparation process of self-healing polyurethane is as follows: heat polyether polyol to 120°C for vacuum dehydration, then cool down to 75°C, add toluene diisocyanate dropwise, react for 2.5h, cool down to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com