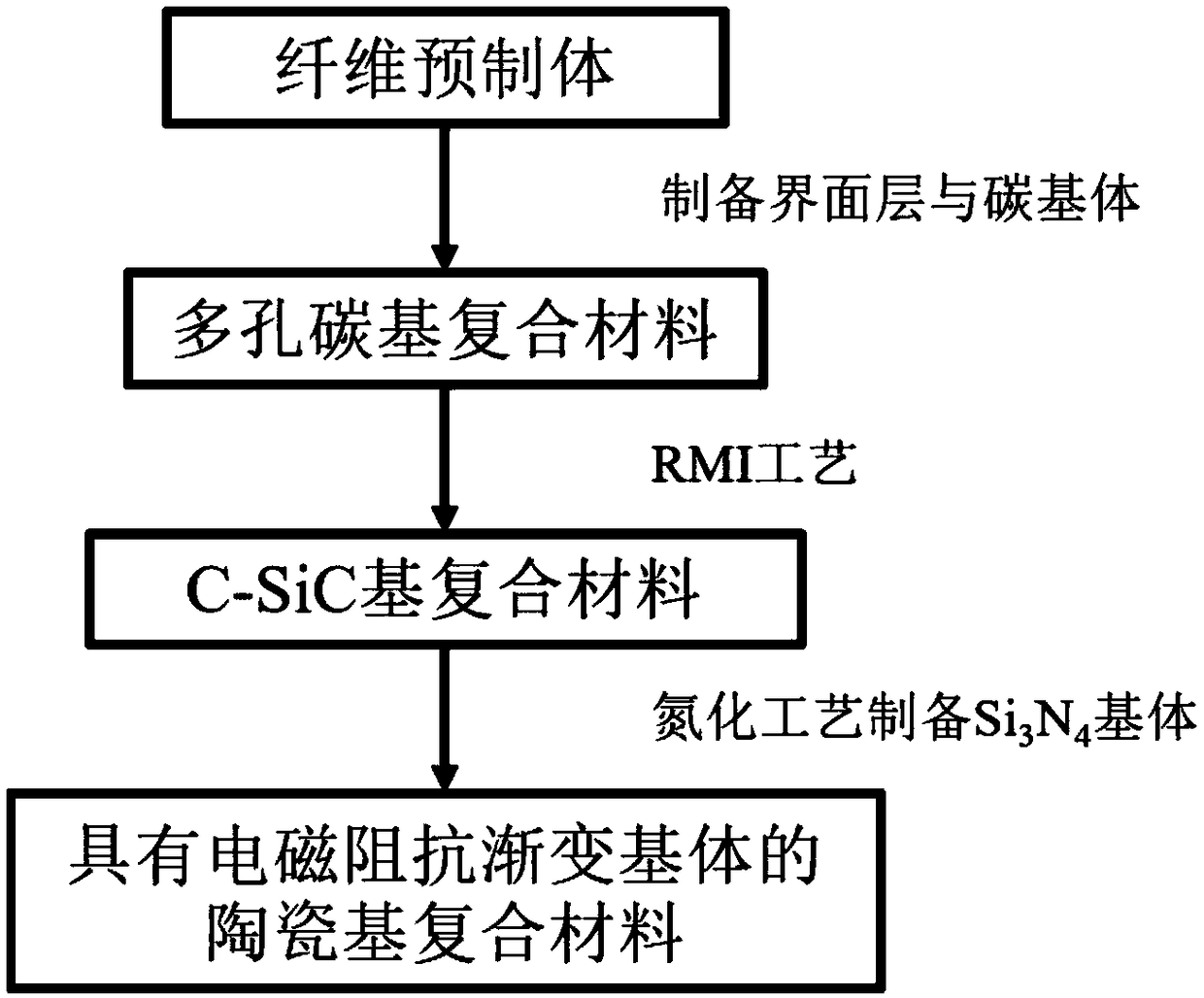

Quick preparation method of wave-absorbing ceramic-based composite material with electromagnetic-impedance gradient matrix

A composite material and impedance gradual change technology, which is applied in the field of rapid preparation of wave-absorbing ceramic matrix composite materials, can solve the problems that limit the wide application of ceramic matrix composite materials, long process cycle, and increase the cost of material preparation, so as to achieve excellent oxidation resistance and improve The effect of microwave absorption performance and short preparation cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

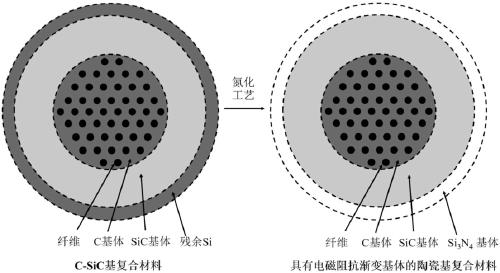

[0024] Example 1: Using two-dimensional laminated high-resistance SiC fibers with a fiber volume fraction of 35% as a preform, a uniform BN interface layer (with a thickness of 500 nm) was prepared on the inside / surface of the preform by the CVI method. Using propylene as the precursor gas, pyrolytic carbon was deposited on the prefabricated body with the interface layer by CVI method. The deposition temperature was 1000 °C and the deposition time was 500 h. Porous SiC with an open porosity of about 30% was prepared. f / C Composite. In the resulting SiC f The surface of the / C composite material is coated with industrial silicon powder with a particle size of 10 μm, placed in a vacuum furnace with an absolute pressure of 1000 Pa, and the temperature is raised to 1500 °C at a rate of 30 °C / min, and kept for 1 hour, so that the silicon is melted and infiltrated into the pores. SiC f / C composite material preform, and react with C matrix to form SiC, and then cool down to room ...

Embodiment 2

[0025] Example 2: Two-dimensional semi-transparent wave-type Si with a fiber volume fraction of 30% using the CVI process 3 N 4 A uniform BN interface layer (500nm in thickness) was prepared inside / on the surface of the fiber preform. Using phenolic resin as the organic precursor of C, the C matrix was prepared inside the prefabricated body with the interface layer prepared by the PIP process, and a porous Si with an open porosity of about 30% was obtained. 3 N 4f / C Composite. In the resulting Si 3 N 4f The surface of the / C composite material prefabricated body is coated with industrial silicon powder with a particle size of 10 μm, placed in a vacuum furnace with an absolute pressure of 1000 Pa, and the temperature is raised to 1500 °C at a heating rate of 30 °C / min, and kept for 1 hour to melt and infiltrate the silicon to porous Si 3 N 4f / C composite material preform, and react with C matrix to form SiC, and then cool down to room temperature at a rate of 10°C / min....

Embodiment 3

[0026] Example 3: Two-dimensional laminated wave-transparent Al with a fiber volume fraction of 45% using the CVI process 2 o 3 A uniform BN interface layer (500nm in thickness) was prepared inside / on the surface of the fiber preform. The preform with the BN interface layer was placed in a pyrolytic carbon deposition furnace, and the pyrolytic carbon matrix was prepared by the CVI method at 1000 °C with methane as the precursor gas to obtain porous two-dimensional Al 2 o 3f The prefabricated body of / C composite material has a porosity of about 35vol.%, which is ultrasonically cleaned and dried for use. In the resulting SiC f The surface of the / PyC composite preform is coated with industrial silicon powder with a particle size of 20 μm, placed in a vacuum furnace with an absolute pressure of 1000 Pa, and the temperature is raised to 1500 °C at a heating rate of 30 °C / min, and the temperature is kept for 0.5 h to melt the silicon. Infiltrated into porous Al 2 o 3f / C pre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com