Boiler water cooling wall high-temperature anti-corrosion anti-staining anti-slagging ceramic coating material

A technology of ceramic coatings and water-cooled walls, applied in the field of coatings, can solve the problems that affect the service life of the coating, cannot solve the problems of high contamination and high-temperature corrosion reductive corrosion, coating cracking, etc., and achieve long service life and low surface energy , the effect of preventing contamination and slagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1) Preparation of binder liquid: slowly add 35 parts of aluminum dihydrogen phosphate into 15.88 parts by mass of water, and stir for 10-20 minutes.

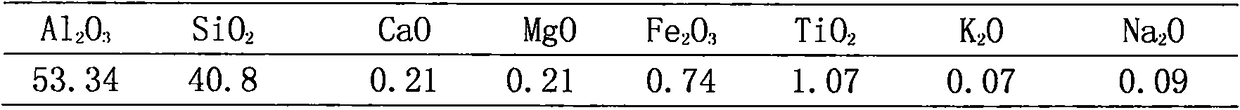

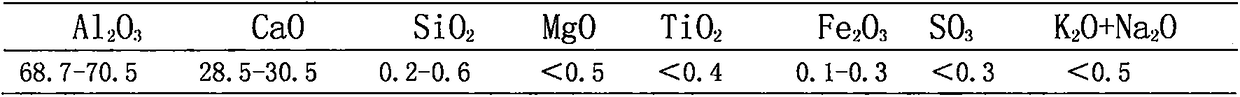

[0046] 2) Preparation of filler mixture: 27.5 parts by mass of synthetic mullite, 9.9 parts by mass of corundum powder, 1.5 parts by mass of pure calcium aluminate micropowder, 3.2 parts by mass of activated alumina micropowder, 1.8 parts by mass of silicon micropowder , 3.0 parts by mass of expansion agent (andalusite), 2.0 parts by mass of sintering agent (spodumene), 0.10 parts by mass of water reducer (composite phosphate), 0.12 parts by mass of anti-knock agent (organic fiber) are mixed in the ball mill Grind until the fineness reaches ≤5 μm.

[0047] 3) Add the filler mixture to the binder liquid, then add 0.7 part of dispersant, 0.2 part of wetting agent, and 0.5 part of defoamer, stir at 1000 rpm for 40 minutes, mix evenly and filter before packaging.

[0048] Examples 2 to 9, the proportions are shown in Table 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com