Rapid solidifying and shaping equipment for high-pressure cast aluminum alloy workpiece

A rapid solidification and aluminum alloy technology, which is applied in the field of high-pressure casting aluminum alloy related equipment, can solve the problems of slow solidification and shaping of workpieces, waste of raw materials for workpieces, and increase in manufacturing costs, so as to achieve fast curing and shaping, reduce unqualified products, and save The effect of product raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

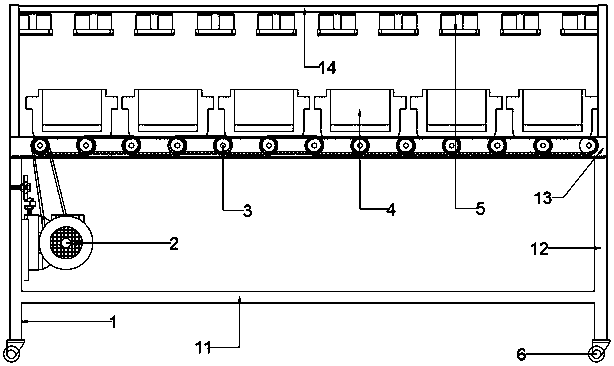

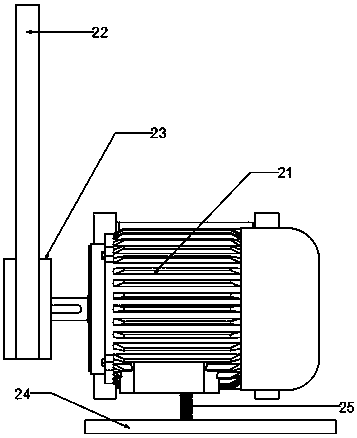

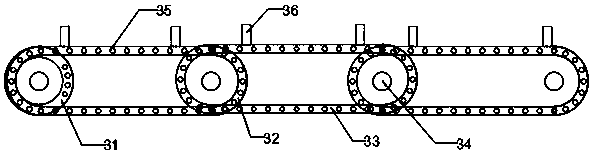

[0024] see Figure 1-5 , in an embodiment of the present invention, a high-pressure cast aluminum alloy workpiece rapid solidification and shaping equipment includes a frame assembly 1 and a roller 6, the roller 6 is fixedly installed at the bottom of the frame assembly 1, and the frame assembly 1 includes a bottom plate 11 , side plate 12, support plate 13 and top plate 14, described side plate 12 is two, and two side plates 12 are arranged in parallel, and described bottom plate 11 is installed on the bottom of side plate 12, and described top plate 14 is installed on side plate 12 The top end, the support plate 13 is installed in the middle of the side plate 12; also includes a drive assembly 2, a transmission assembly 3, a mold assembly 4 and a heat dissipation assembly 5, the drive assembly 2 is fixedly installed on the side plate 12, the drive assembly 2 is connected with the transmission assembly 3, the transmission assembly 3 is installed on the support plate 13, the m...

Embodiment 2

[0032] In an embodiment of the present invention, a casting solidification and shaping production line including rapid solidification and shaping equipment for high-pressure cast aluminum alloy workpieces is provided. The structure of the rapid solidification and shaping equipment for high-pressure cast aluminum alloy workpieces is the same as that described in Embodiment 1.

[0033] It should be further explained that the specific workflow of the present invention is:

[0034] Place the high-pressure cast aluminum alloy workpiece to be formed in the mold assembly 4, start the drive assembly 2 and the heat dissipation assembly 5, the cooling plate 43 in the mold assembly 4 quickly absorbs the heat of the workpiece to cool and solidify it, and at the same time the heat dissipation assembly 5 blows out The wind further cools and solidifies the workpiece in the inner mold 41 to complete the rapid solidification and finalization of the high-pressure cast aluminum alloy workpiece to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com