Manufacturing process and structure of a spiral channel sand core mold for water-cooled motor casings of new energy vehicles

A new energy vehicle, sand core mold technology, applied in the direction of manufacturing tools, cores, casting molding equipment, etc., can solve the problem that the spiral water cooling channel cannot be formed normally, the structure of the water channel sand core mold is unstable, and the motor shell is easy to disperse, etc. problems, to achieve the effect of long storage time, fast molding and curing speed, and not easy to fall apart

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described further:

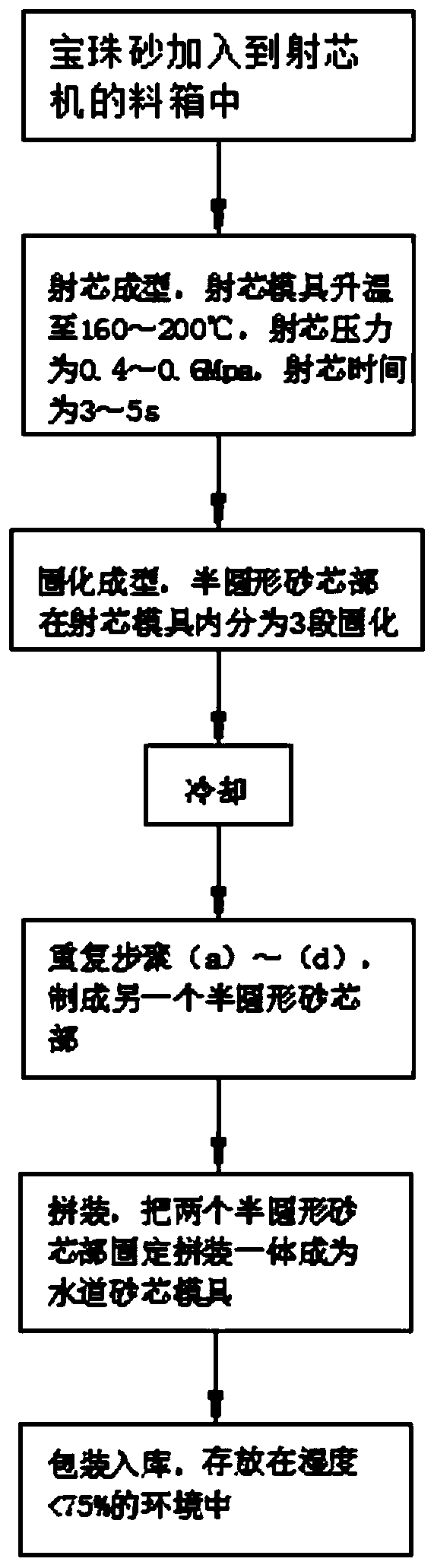

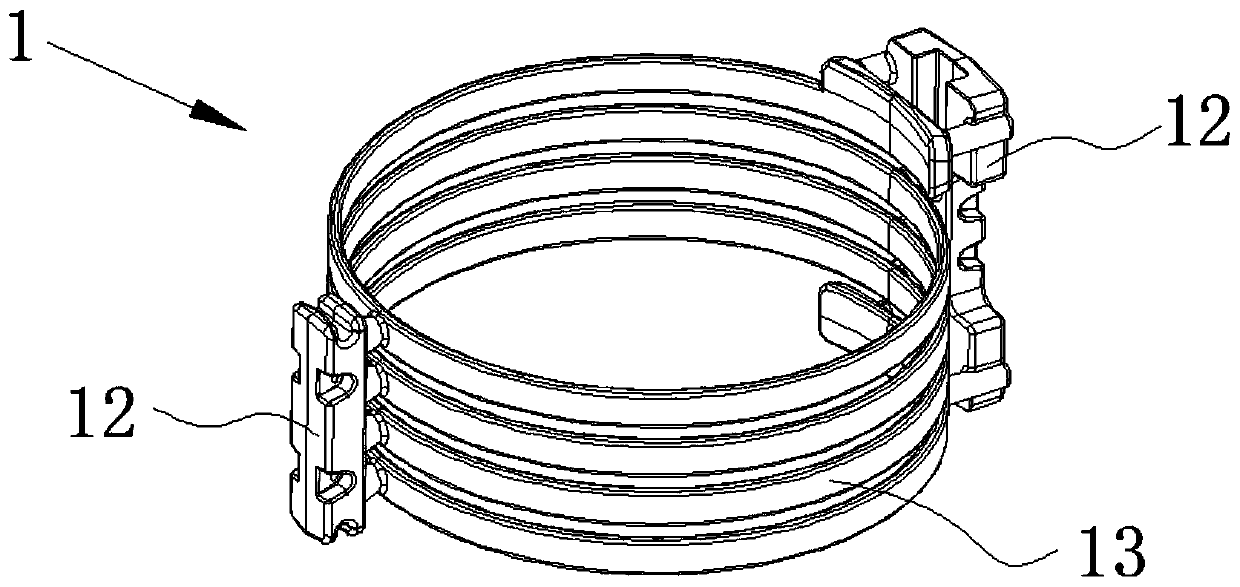

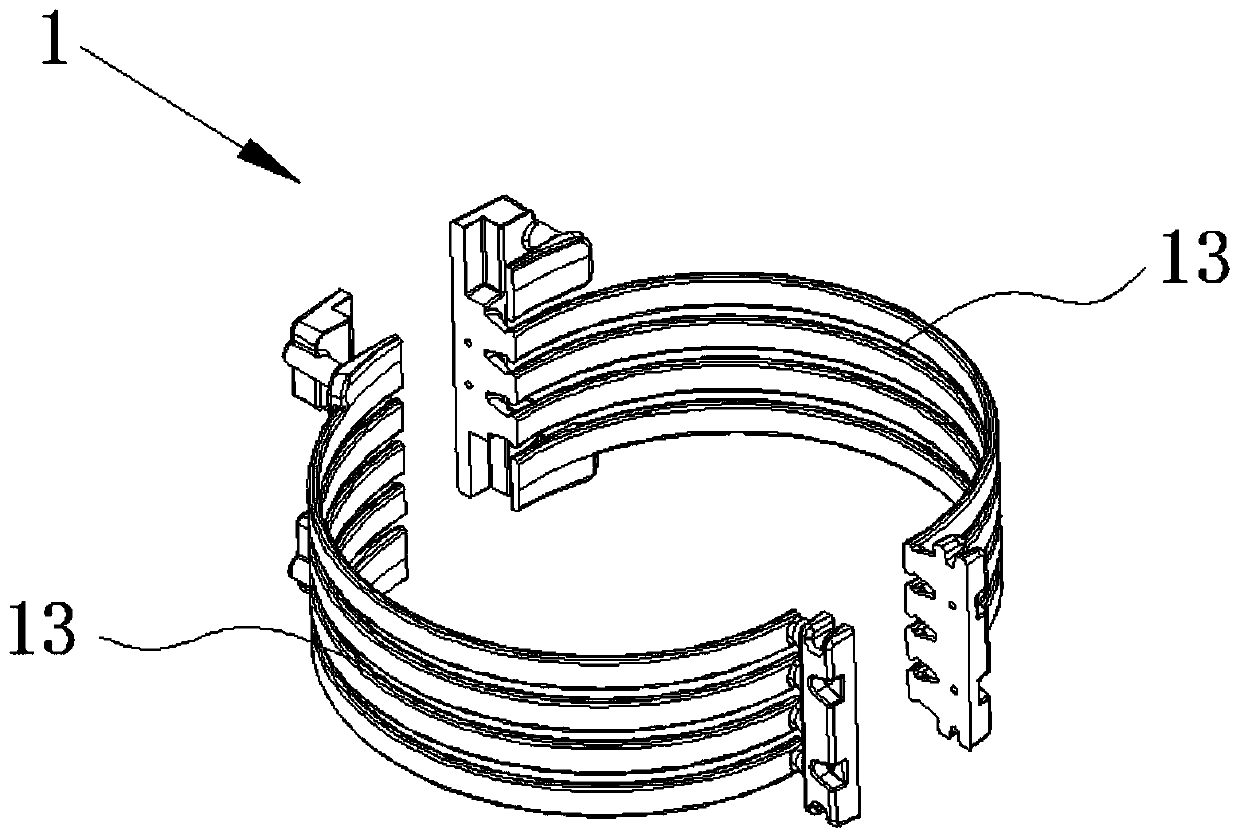

[0025] Such as figure 1 and figure 2 As shown, a new energy vehicle water-cooled motor casing spiral water channel sand core mold manufacturing process, the water channel sand core mold 1 is assembled from two semicircular sand core parts, followed by the following steps,

[0026] (a) Add raw materials, make from 70 to 85% AL 2 o 3 , 3~20%SiO2 2 , 1 ~ 3.5% TiO2 mixed pearl sand into the material box of the core shooter;

[0027] (b) Core-shooting molding, the core-shooting mold is heated to 160-200°C, the core-shooting pressure is 0.4-0.6Mpa, the core-shooting time is 3-5s, and the semicircular sand core is initially formed in the core-shooting mold;

[0028] (c) Curing molding, the semicircular sand core is divided into three stages of curing in the core shooting mold, the first stage of curing temperature is 160-180°C and the time is 50s, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com