Hot melt adhesive capable of being rapidly formed at low temperature and excellent in boiling resistance and preparation method thereof

A technology of hot-melt adhesives and formulations, applied in the direction of adhesives, etc., can solve the problems of poor boiling resistance, easy softening and falling off, high sizing temperature, etc., and achieve fast molding speed, excellent boiling resistance and low melting temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

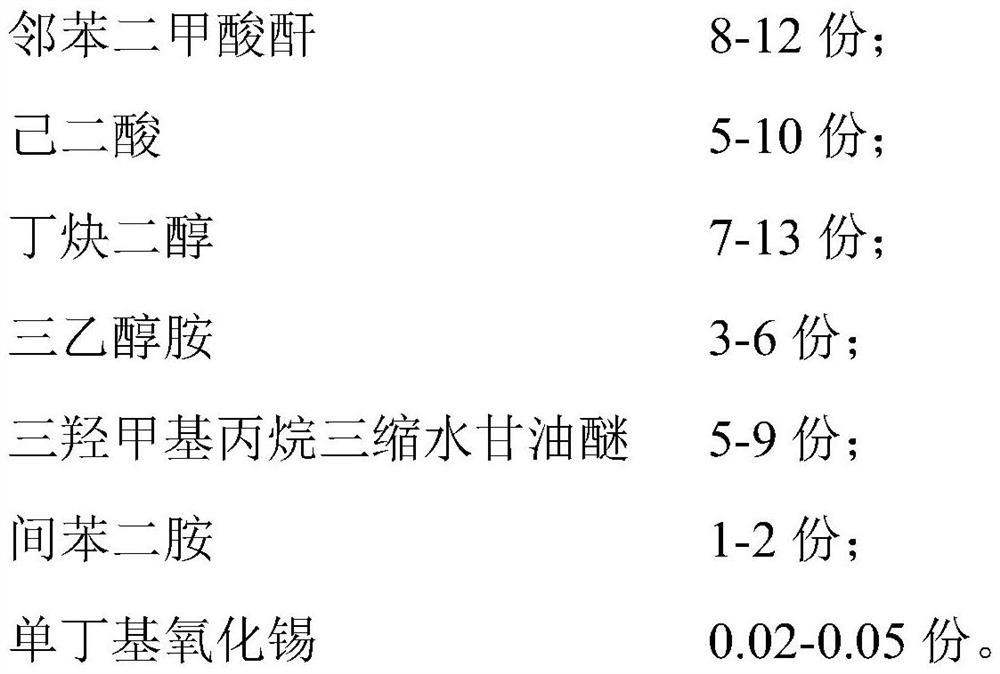

[0028] A method for preparing a hot melt adhesive, comprising the following raw materials in molar parts:

[0029]

[0030] Further, the preparation method comprises the following steps:

[0031] A. Add the formula amount of butynediol and triethanolamine into the reaction kettle, heat up to 110°C for full melting, then add the formula amount of phthalic anhydride, adipic acid and monobutyltin oxide, / h Gradually raise the temperature to 200°C, and keep warm for reaction;

[0032] B. When the acid value of the system mixture is reduced to 58mgKOH / g, lower the temperature to 120°C, add the prescribed amount of trimethylolpropane triglycidyl ether, and continue the heat preservation reaction;

[0033] C. When the acid value of the system mixture is less than 10mgKOH / g, and the epoxy equivalent is 875g / mol, cool down to 95°C, and then add m-phenylenediamine in the formulated amount to melt and mix for 1min;

[0034] D. After mixing evenly, the material is then discharged thr...

Embodiment 2

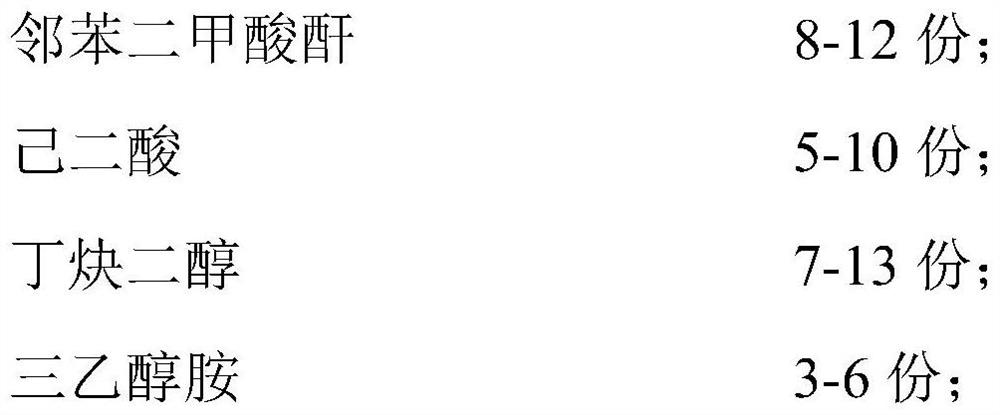

[0037] A method for preparing a hot melt adhesive, comprising the following raw materials in molar parts:

[0038]

[0039] Further, the preparation method comprises the following steps:

[0040] A. Add the formula amount of butynediol and triethanolamine into the reaction kettle, heat up to 120°C for full melting, then add the formula amount of phthalic anhydride, adipic acid and monobutyltin oxide, / h Gradually raise the temperature to 210°C, and keep warm for reaction;

[0041] B. When the acid value of the system mixture is reduced to 51mgKOH / g, lower the temperature to 130°C, add the formulated amount of trimethylolpropane triglycidyl ether, and continue the heat preservation reaction;

[0042] C. When the acid value of the system mixture is less than 10mgKOH / g, and the epoxy equivalent is 812g / mol, the temperature is lowered to 100°C, and then the m-phenylenediamine of the formulated amount is added to melt and mix for 0.5min;

[0043] D. After mixing evenly, the ma...

Embodiment 3

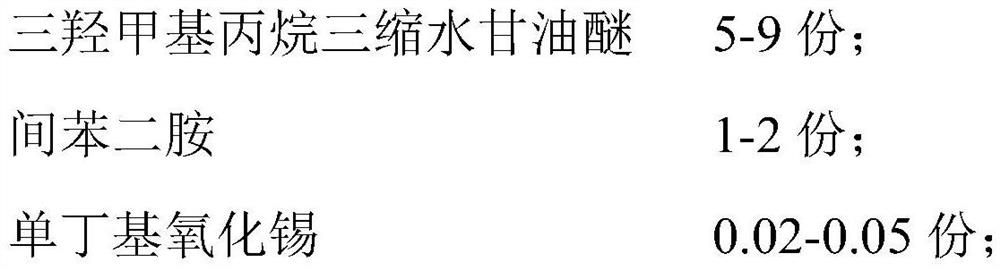

[0046] A method for preparing a hot melt adhesive, comprising the following raw materials in molar parts:

[0047]

[0048] Further, the preparation method comprises the following steps:

[0049] A. Add the formula amount of butynediol and triethanolamine into the reaction kettle, heat up to 110°C for full melting, then add the formula amount of phthalic anhydride, adipic acid and monobutyltin oxide, / h Gradually raise the temperature to 205°C, and keep warm for reaction;

[0050] B. When the acid value of the system mixture is reduced to 56mgKOH / g, lower the temperature to 125°C, add the prescribed amount of trimethylolpropane triglycidyl ether, and continue the heat preservation reaction;

[0051] C. When the acid value of the system mixture is less than 10mgKOH / g, and the epoxy equivalent is 960g / mol, cool down to 98°C, and then add m-phenylenediamine in the formulated amount to melt and mix for 1min;

[0052] D. After mixing evenly, the material is then discharged thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

| Acid value | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com