Paint-spraying device with desusting and drying integrated structure

An all-in-one, drying cavity technology, applied in liquid spraying devices, devices for coating liquid on surfaces, spraying devices, etc., can solve problems such as low drying efficiency, internal heat loss, affecting production efficiency, etc., to ensure long-term Use, prolong the service life, improve the effect of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

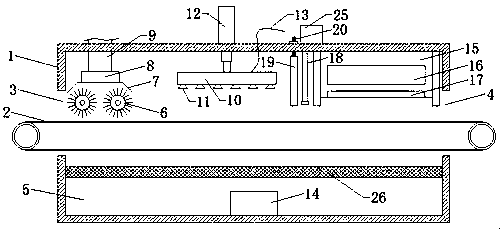

[0019] Please refer to the figure, in the embodiment of the present invention, a dust-removing and drying-integrated paint spraying device includes a housing 1, a conveyor belt 2, a feed port 3, a discharge port 4 and a paint collection tank 5; Port 3 and discharge port 4 are set on the left and right sides of the housing 1 respectively, and the conveyor belt 2 passes through the feed port 3 and the discharge port 4 on the left and right sides at the same time horizontally, so that the wood placed on the conveyor belt 2 flows from the left to the right. Conveying to the right, the bottom in the housing 1 is set as a paint collection tank 5, which stores a large amount of paint in the paint collection tank 5, and is also convenient to collect the paint dripping from the top.

[0020] The conveyor belt 2 is formed by connecting a plurality of support rods 22 of elongated structure through connecting rubber strips 24. The material of the connecting rubber strips 24 is rubber, and ...

Embodiment 2

[0025] In the paint collection tank 5, a horizontal filter screen 26 is detachably installed by bolts, filters the impurities in the paint above by the filter screen 26, reduces the impurities of the paint in the paint collection tank 5, and is installed at the bottom of the paint collection tank 5 Paint pump 14 extracts the paint in the paint collection tank 5, and the other end of the paint pump 14 is communicated on the paint input pipe 13 by a tee, so that the paint in the paint collection tank 5 can be reused, reducing the waste of paint.

[0026]The wood to be painted is placed on the conveyor belt 2 at the left end, and the conveyor belt 2 transports the wood on it to the right. First, the wood is cleaned by a plurality of brush rollers 6, and the dust and impurities on the surface of the wood are swept up and suspended in the air. At the same time The vacuum blower 8 extracts the swept air, so that the dust is discharged through the exhaust pipe 9, reducing the dust in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com