Chemical forming process of a lithium ion battery

A lithium-ion battery and process technology, which is applied in the field of lithium-ion battery formation process, can solve problems such as electrolyte gushing out and difficult control of gas production speed, and achieve the effects of eliminating polarization, excellent performance, and avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

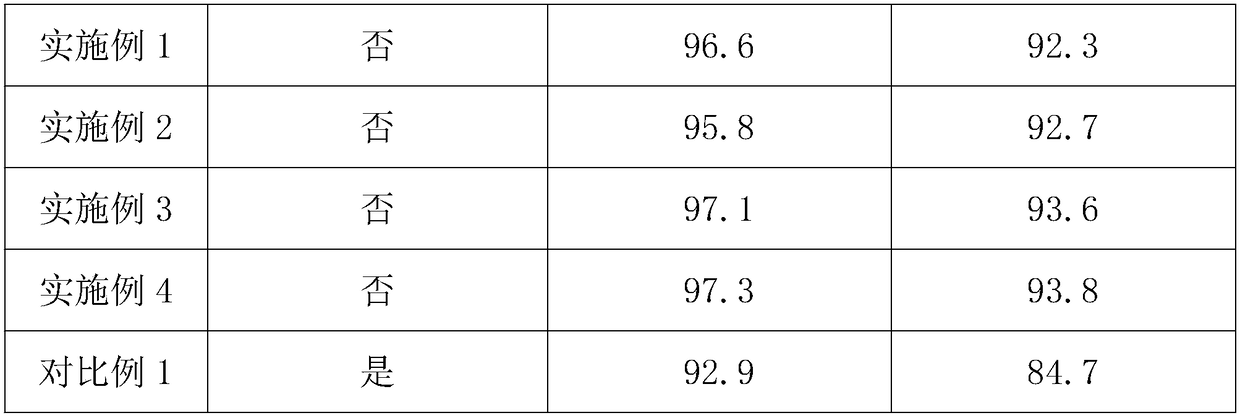

Examples

Embodiment 1

[0035] 1), inject the first electrolytic solution accounting for 50% of the total volume of the electrolytic solution to the lithium-ion battery to be injected, the first electrolytic solution includes an electrolyte salt, a non-aqueous solvent and an additive of 3% volume, and the electrolytic salt is A mixed electrolyte salt of 1.5mol / L lithium hexafluorophosphate and 0.01mol / L sodium bisoxalate borate, the non-aqueous solvent is ethylene carbonate, the additive is vinylene carbonate, and the battery after liquid injection is placed on the chemical conversion device, so Said chemical conversion device is located in the glove box;

[0036] 2), repeat the process of vacuuming-introducing nitrogen 4 times, adjust the air pressure in the glove box to 0.01MPa, and let it stand for 0.1h; the nitrogen contains 500ppm nitric oxide;

[0037] 3), feed the nitrogen gas, adjust the pressure in the sealing device to 0.3MPa, charge with a constant current of 0.02C, and charge to the first...

Embodiment 2

[0048] 1), inject the first electrolytic solution accounting for 70% of the total volume of the electrolytic solution to the lithium-ion battery to be injected, the first electrolytic solution includes an electrolyte salt, a non-aqueous solvent and an additive of 5% volume, and the electrolytic salt is A mixed electrolyte salt of 1.8mol / L lithium hexafluorophosphate and 0.02mol / L sodium bisoxalate borate, the non-aqueous solvent is ethylene carbonate, the additive is ethylene sulfite, the battery after the liquid injection is placed on the chemical conversion device, the Said chemical conversion device is located in the glove box;

[0049] 2), repeat the process of vacuuming-introducing nitrogen 4 times, adjust the air pressure in the glove box to 0.01MPa, and let it stand for 1h; the nitrogen contains 2000ppm nitric oxide;

[0050] 3), feed the nitrogen gas, adjust the pressure in the sealing device to 0.5MPa, charge with a constant current of 0.05C, and charge to the first s...

Embodiment 3

[0061] 1), inject the first electrolytic solution accounting for 60% of the total volume of the electrolytic solution to the lithium-ion battery to be injected, the first electrolytic solution includes electrolyte salt, non-aqueous solvent and 4% volume additive, and the electrolytic salt is A mixed electrolyte salt of 1.6mol / L lithium hexafluorophosphate and 0.01mol / L sodium bisoxalate borate, the non-aqueous solvent is ethylene carbonate, the additive is vinylene carbonate, and the battery after the liquid injection is placed on the chemical conversion device. Said chemical conversion device is located in the glove box;

[0062] 2), repeat the process of vacuuming-introducing nitrogen 4 times, adjust the air pressure in the glove box to 0.01MPa, and let it stand for 1h; the nitrogen contains 1000ppm nitric oxide;

[0063] 3), feed the nitrogen gas, adjust the pressure in the sealing device to 0.4MPa, charge with a constant current of 0.04C, and charge to the first set voltag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com