Batch transfer device and transfer method for microchip

A transfer device and chip technology, applied in transportation and packaging, conveyor objects, furnaces, etc., can solve problems such as efficiency, yield and transfer accuracy, and practical application obstacles.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

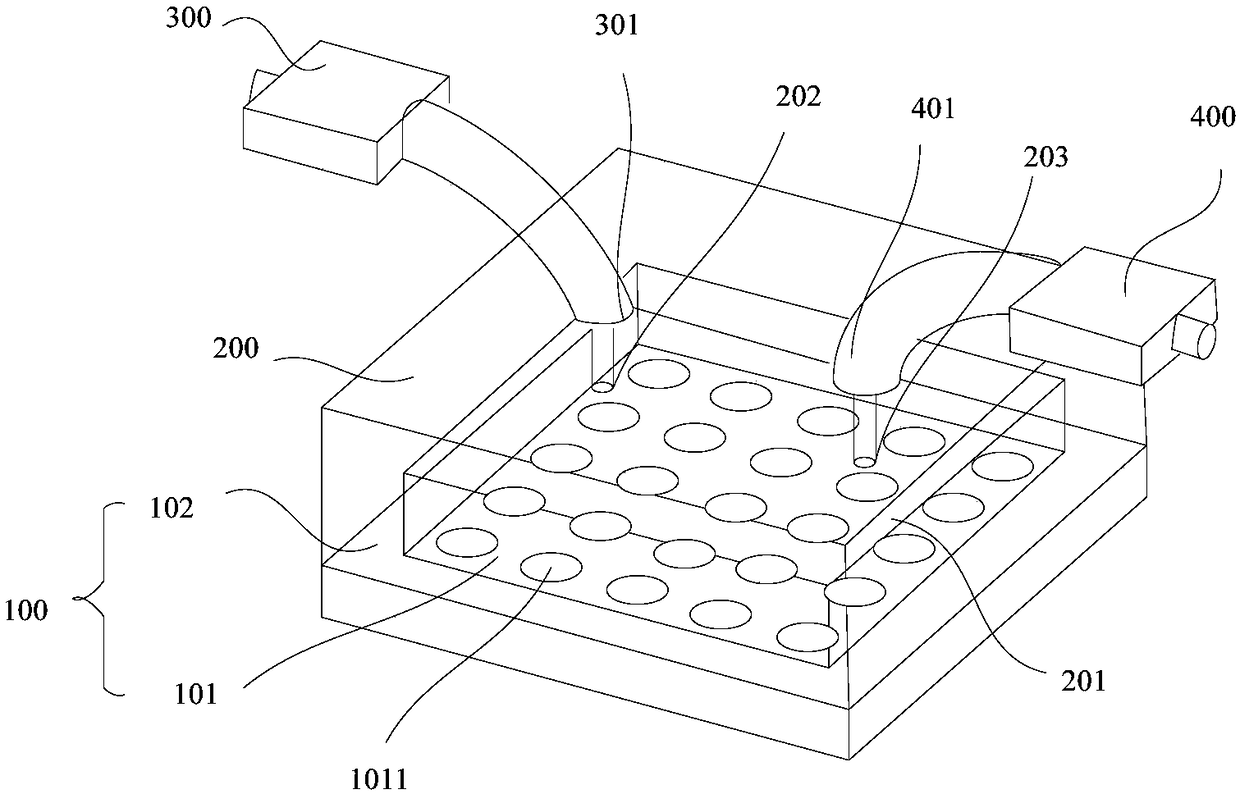

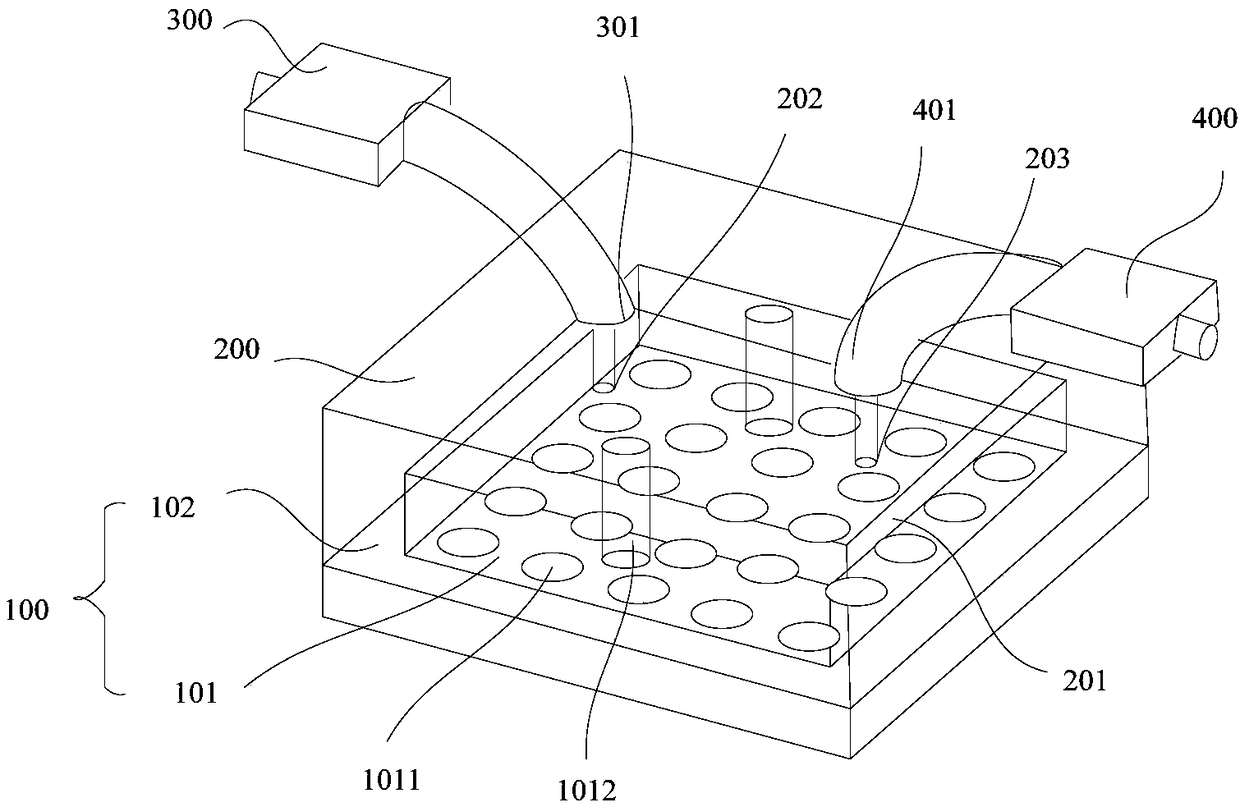

[0036] Embodiments of the present invention provide a batch transfer device for microchips. see figure 1 , the batch transfer device for microchips specifically includes: a loading mold 100, the loading mold 100 includes a loading area 101 and a non-loading area 102 located at the edge of the loading area 101; a plurality of chip suction holes arranged in an array formed on the loading area 101 1011; the outer cover 200 formed on the non-loading area 102, the cavity 201 is formed between the outer cover 200 and the loading mold 100; the air suction holes 202 and the inflation holes 203 formed on the outer cover 200; The input port 301 is sealedly connected to the air suction hole 202 for extracting the gas in the chamber 201 ; the inflator 400 , the output port 401 of the inflator 400 is sealedly connected to the inflation hole 203 for inflating the chamber 201 .

[0037] Through high-precision equipment, a large number of microchips are arranged on the target substrate or ci...

Embodiment 2

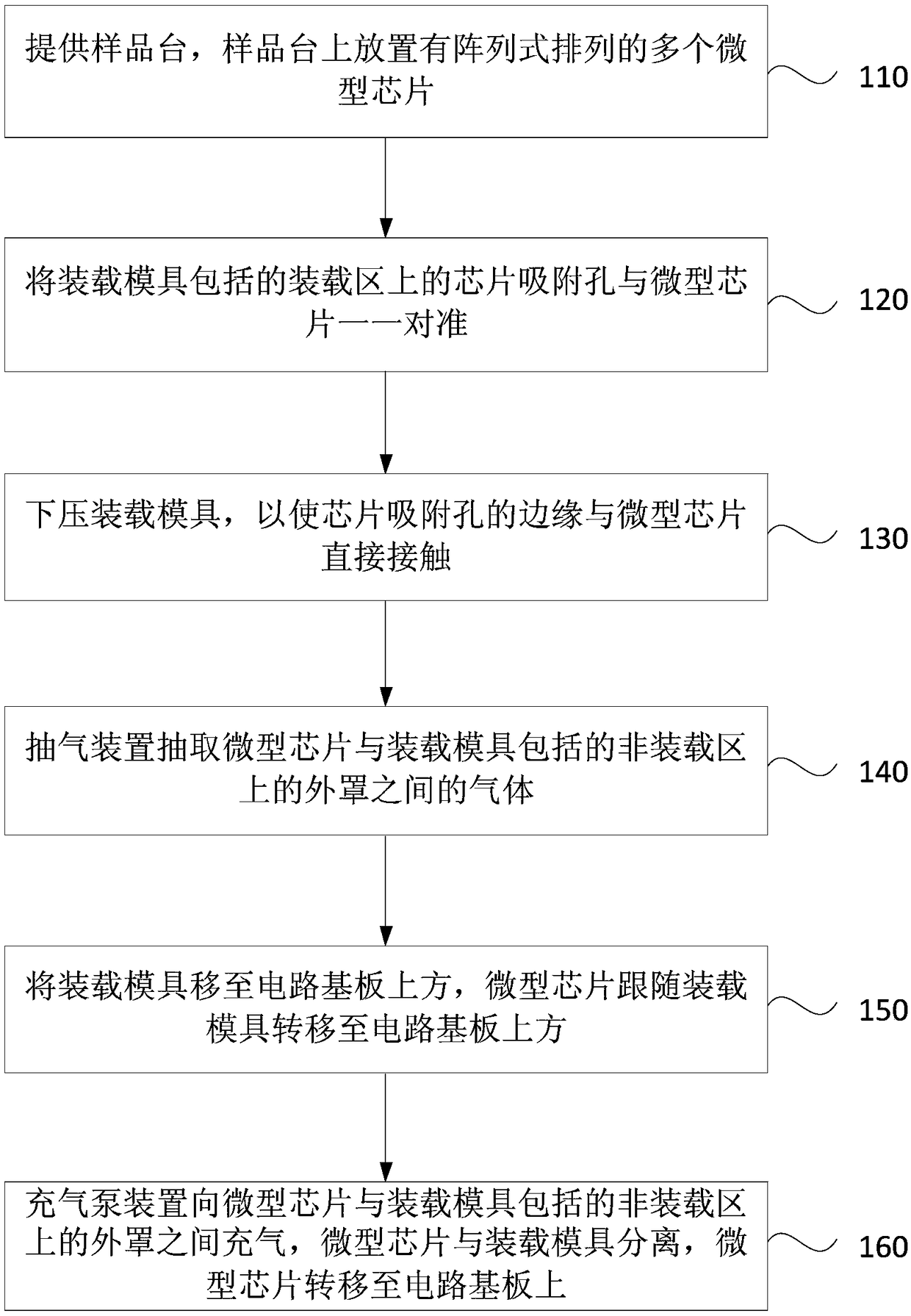

[0048] Based on the same concept as the above-mentioned embodiments, the embodiments of the present invention provide a batch transfer method for microchips, see image 3 , the method steps are as follows:

[0049] Step 110 , providing a sample stage on which a plurality of microchips arranged in an array are placed.

[0050] see Figure 4 , a sample stage 500 is provided, and a plurality of microchips 501 arranged in an array are placed on the sample stage 500 .

[0051] In this embodiment, the micro chip is exemplarily a micro light emitting diode chip. The specific preparation method of the miniature light-emitting diode chip can use metal organic chemical vapor deposition, deposit a gallium nitride GaN epitaxial layer on a clean sapphire substrate, and the epitaxial layer includes but is not limited to n-type GaN epitaxial layer, multiple quantum well layer, p-type GaN layer The epitaxial layer is made by lithography, cleaning, etching, electrode deposition and other ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com