Multiphase high-entropy alloy and preparation method thereof

A high-entropy alloy and alloy technology, applied in the field of high-performance advanced structural materials, can solve the problems of insufficient plasticity and toughness, high strength, etc., and achieve the effect of improving purity, strong bonding ability, high temperature oxidation resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

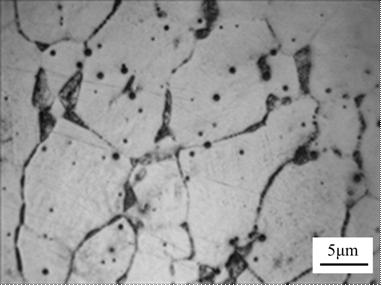

[0026] Example 1: High Entropy Alloy with FeCrNiAlNb Base Composition

[0027] The first designed composition system is: 30Fe-22Cr-32Ni-15Al-1.0Nb (at.%). The raw material is a high-purity metal block, which is smelted according to the above method-casting molding. The actual measured chemical composition of the high-entropy alloy is: 30.2Fe-21.9Cr-31.8Ni-14.7Al-1.1Nb (at.%), which is similar to the design composition content. Its as-cast microstructure is as figure 2 As shown, it can be seen that its microstructure is based on the BCC structure and contains part of the eutectic group structure. The mechanical properties in Table 1 show that the tensile strength and yield strength at room temperature are greater than 2 times that of the comparative example nickel-based alloy 718, and the mechanical properties at high temperatures are less obvious compared with the comparative example; but the elongation after fracture There is still room for improvement. Under this compos...

Embodiment 2

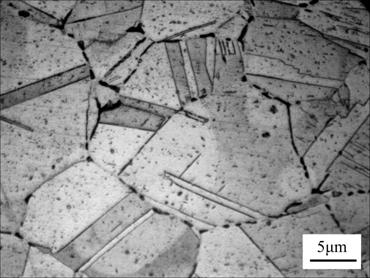

[0028] Example 2: Adding Mo to FeCrNiAlNb basic high-entropy alloy

[0029] On the basis of Example 1, Mo element is added, and the design value of Mo element is 2.2 at.%. The designed composition system is: 32Fe-21Cr-32Ni-12Al-0.8Nb-2.2Mo (at.%). Its as-forged microstructure is as follows: figure 2 As shown, it can be seen that the grains are elongated, and a small amount of dendrites are crushed and distributed at the grain boundaries. The performance test results are shown in Table 1. It can be seen that after adding Mo, the room temperature strength of the steel plate is significantly improved, the tensile strength is increased by about 150MPa compared with Example 1, the yield strength is increased by about 100MPa, and the microhardness is increased by 25Hv. The strengthening effect is significant. But the elongation after break of Example 2 is still not ideal compared with the comparative example. Example 2 shows that the addition of Mo can increase the strength of s...

Embodiment 3

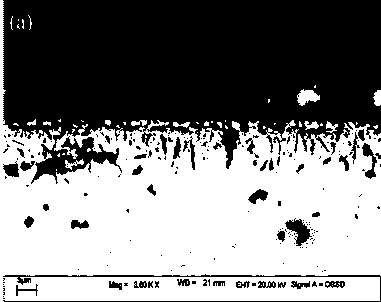

[0030] Example 3: FeCrNiAlNb based high-entropy alloy with addition of Cu and Y

[0031] The raw material, smelting and thermal processing process are as above. The designed composition system is: 25Fe-20Cr-25Ni-9Al-0.6Nb-20Cu-0.4Y (at.%). After the above smelting---casting---homogenization---forging---aging and then, its microstructure is as follows: image 3 As shown, it can be seen that the precipitates are dispersedly distributed in the austenite matrix. Its properties are shown in Table 1. After adding Cu combined with Y, the room temperature and high temperature strengths are higher than the corresponding strength of the comparative example. At the same time, the elongation is significantly higher than that of Examples 1 and 2, close to the elongation of the comparative example. The room temperature tensile strength of the aged high-entropy alloy increased by 62.2% compared with the comparison; the 700°C high temperature tensile strength increased by 5.4%; the room tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com