High-barrier PVA-based composite film and preparation method thereof

A high-barrier, composite film technology, applied in the field of packaging film materials, can solve problems such as swelling and film performance degradation, and achieve the effect of increased internal friction, high mechanical properties, and less relative slippage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

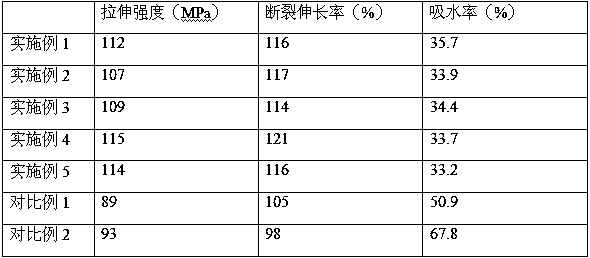

Examples

Embodiment 1

[0021] A high-barrier PVA-based composite film, the following components are weighed by weight: 20 parts of corn starch, 50 parts of PVA, 10 parts of modified hydrotalcite, 30 parts of keratin solution, 10 parts of sodium carboxymethyl cellulose, polyethylene glycol 15 parts of diol, 3 parts of crosslinking agent, 10 parts of trimethylolpropane, 100 parts of water;

[0022] The modification method of hydrotalcite is as follows: add hydrotalcite to 50% ethanol aqueous solution, heat to 60°C, stir at constant temperature for 2 hours, then add potassium lauryl ether phosphate, adjust pH to 4, and react at 60°C 4h, it can be filtered, washed and dried, wherein the mass ratio of hydrotalcite to potassium lauryl ether phosphate is 5:1;

[0023] Further, the crosslinking agent is a mixture of boric acid, polyethylene glycol diglycidyl ether and glutaraldehyde, the mass ratio of which is 1:2:2.

[0024] The preparation method of above-mentioned a kind of high barrier property PVA bas...

Embodiment 2

[0030] A high-barrier PVA-based composite film, the following components are weighed by weight: 30 parts of cornstarch, 40 parts of PVA, 20 parts of modified hydrotalcite, 50 parts of keratin solution, 20 parts of sodium carboxymethylcellulose, polyethylene glycol 5 parts of diol, 10 parts of crosslinking agent, 3 parts of glycerin, 150 parts of water;

[0031] The modification method of hydrotalcite is as follows: add hydrotalcite to 50% ethanol aqueous solution, heat to 60°C, stir at constant temperature for 2 hours, then add potassium lauryl ether phosphate, adjust pH to 4, and react at 60°C 4h, it can be filtered, washed and dried, wherein the mass ratio of hydrotalcite to potassium lauryl ether phosphate is 4:1;

[0032] Further, the crosslinking agent is a mixture of boric acid, polyethylene glycol diglycidyl ether and glutaraldehyde, the mass ratio of which is 1:1:2.

[0033] The preparation method of above-mentioned a kind of high barrier property PVA base composite f...

Embodiment 3

[0039] A high-barrier PVA-based composite film, the following ingredients are weighed in parts by weight: 22 parts of corn starch, 48 parts of PVA, 12 parts of modified hydrotalcite, 35 parts of keratin solution, 12 parts of sodium carboxymethyl cellulose, polyethylene glycol 12 parts of diol, 7 parts of crosslinking agent, 8 parts of trimethylolpropane, 120 parts of water;

[0040] The modification method of hydrotalcite is as follows: add hydrotalcite to 50% ethanol aqueous solution, heat to 60°C, stir at constant temperature for 2 hours, then add potassium lauryl ether phosphate, adjust pH to 4, and react at 60°C 4h, it can be filtered, washed and dried, wherein the mass ratio of hydrotalcite to potassium lauryl ether phosphate is 5:1;

[0041] Further, the crosslinking agent is a mixture of boric acid, polyethylene glycol diglycidyl ether and glutaraldehyde, the mass ratio of which is 1:2:1.

[0042] The preparation method of above-mentioned a kind of high barrier propert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com