Degradable compound fertilizer anti-blocking agent produced through natural grease and preparation method

An anti-caking agent and natural oil technology, applied in application, fertilization equipment, fertilizer mixture, etc., can solve the problems of weak hydrophobicity of vegetable oil, environmental hazards, unpleasant odor, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

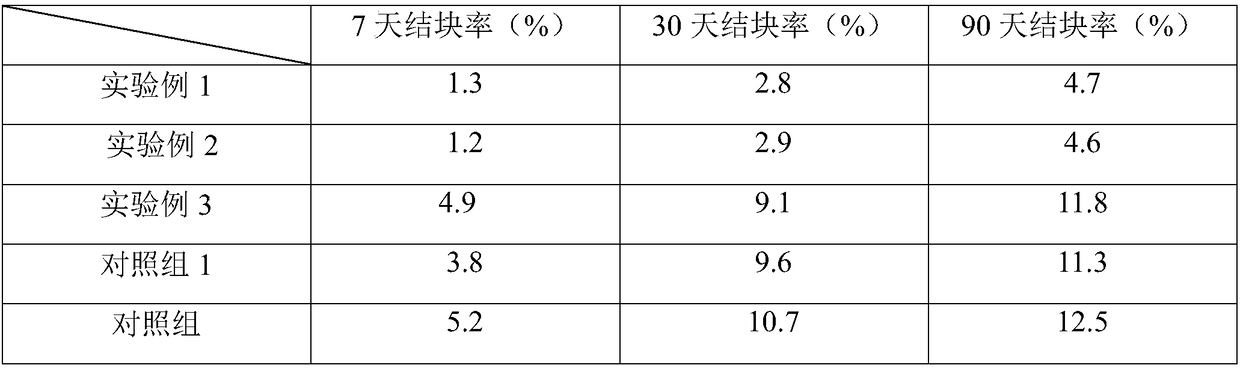

Embodiment 1

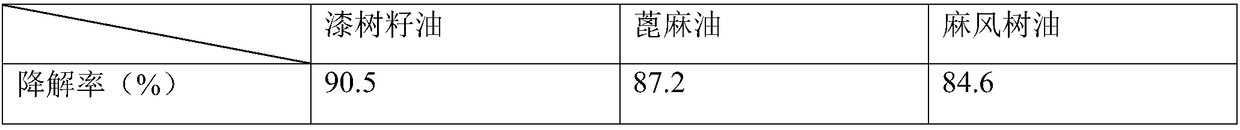

[0035] In a 500L reaction kettle, 20kg of sumac oil, 30kg of castor oil, and 15kg of jatropha oil were successively weighed, and slowly heated to 80°C. Start stirring now, add tree wax 10kg, pectin 5kg, acacia gum 8kg and alkyl glucoside 5kg simultaneously, after raw material is added, stir 50min under 150r / min state and get final product.

[0036] The moisture in the sumac oil is 95%. The fatty acid composition of castor oil is: ricinoleic acid 80%-85%, oleic acid 3%-9% and linoleic acid 2%-3%.

Embodiment 2

[0038] In a 500L reactor, 21kg of sumac oil, 28kg of castor oil, and 13kg of jatropha oil were successively weighed, and slowly heated to 80°C. Start stirring now, add sumac wax 9kg simultaneously, pectin 6kg, acacia gum 8kg and alkyl glucoside 6kg, after raw material is added, stir 50min under 150r / min state and get final product.

[0039] The moisture in the sumac oil is 95%. The fatty acid composition of castor oil is: ricinoleic acid 80%-85%, oleic acid 3%-9% and linoleic acid 2%-3%.

Embodiment 3

[0041] In a 500L reaction kettle, 15 parts of sumac oil, 25 parts of castor oil, and 20 parts of jatropha oil were successively weighed, and slowly heated to 70°C. Start stirring at this time, and add 20 parts of tree wax, 6 parts of pectin, 12 parts of gum arabic and 5 parts of alkyl glucoside at the same time. After adding the raw materials, stir at 100 r / min for 60 minutes.

[0042]The moisture in the sumac oil is 95%. The fatty acid composition of castor oil is: ricinoleic acid 80%-85%, oleic acid 3%-9% and linoleic acid 2%-3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com