Method for preparing boron-nitrogen-doped porous carbon material applied to super capacitor under microwave hydrothermal assistance

A supercapacitor and microwave-assisted technology, applied in hybrid capacitor electrodes, applications, household appliances, etc., can solve the problems of complex preparation process, many instruments, and long preparation time of porous carbon materials, and achieve shortened preparation time, fast heating, and improved The effect of binding volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

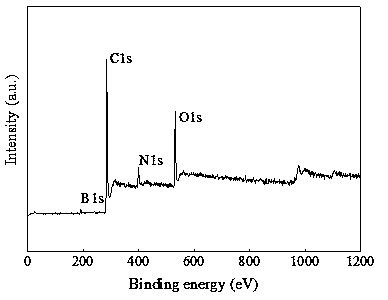

[0024] Preparation of boron-nitrogen co-doped porous carbon material: Take 2g of fir bark powder, put it in a glass beaker, add 8g of ammonium pentaborate tetrahydrate solid, then add 40ml of deionized water, and then use a magnetic stirrer at a speed of 800r / min Stir for 30 minutes, transfer the stirred mixture to a microwave hydrothermal reaction kettle, place it in a microwave hydrothermal synthesizer, and react for 10 minutes at a temperature of 180°C and a pressure of 1.85 MPa. After cooling naturally to room temperature, take it out, and then Dry in a vacuum oven at 105°C for 12h, then place the dried powder in a horizontal tube furnace, sinter at 700°C in a nitrogen atmosphere for 1h, then wash and filter twice with hot water at 90°C, and bake After drying, the boron-nitrogen co-doped porous carbon material is obtained. According to the XPS test, the boron content of the material is 10.14wt%, and the nitrogen content is 15.13wt%.

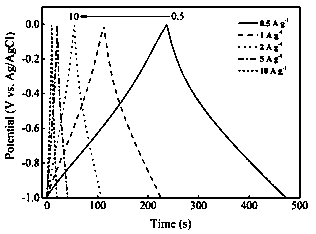

[0025] Supercapacitor electrode prepa...

Embodiment 2

[0027] Preparation of boron-nitrogen co-doped porous carbon material: Take 2g of fir bark powder, put it in a glass beaker, add 8g of ammonium pentaborate tetrahydrate solid, then add 45ml of deionized water, and then use a magnetic stirrer at a speed of 800r / min Stir for 30 minutes, transfer the stirred mixture to a microwave hydrothermal reaction kettle, place it in a microwave hydrothermal synthesizer, and react for 20 minutes at a temperature of 180°C and a pressure of 1.85 MPa. After cooling naturally to room temperature, take it out, and then place it in a microwave hydrothermal synthesizer. Dry in a vacuum oven at 105°C for 12h, then place the dried powder in a horizontal tube furnace, sinter at 800°C for 1h in a nitrogen atmosphere, wash and filter twice with hot water at 90°C, and dry The boron-nitrogen co-doped porous carbon material is obtained. According to the XPS test, the boron content of the material is 13.05wt%, and the nitrogen content is 16.69wt%.

[0028] ...

Embodiment 3

[0030] Preparation of boron-nitrogen co-doped porous carbon material: Take 2g of fir bark powder, put it in a glass beaker, add 8g of ammonium pentaborate tetrahydrate solid, then add 50ml of deionized water, and then use a magnetic stirrer at a speed of 800r / min Stir for 30 minutes, transfer the stirred mixture to a microwave hydrothermal reaction kettle, place it in a microwave hydrothermal synthesizer, react at a temperature of 180°C and a pressure of 1.85MPa for 30 minutes, wait for natural cooling to room temperature, take it out, and place Dry in a vacuum oven at 105°C for 12h, then place the dried powder in a horizontal tube furnace, sinter at 800°C for 1h in a nitrogen atmosphere, wash and filter twice with hot water at 90°C, and dry The boron-nitrogen co-doped porous carbon material is obtained. According to the XPS test, the boron content of the material is 10.19wt%, and the nitrogen content is 17.97wt%.

[0031] Supercapacitor electrode preparation: Take 80 mg of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

| Specific capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com