A modified nickel-cobalt-manganese ternary cathode material and a preparation method thereof

A cathode material, nickel-cobalt-manganese technology, which is applied in the field of modified nickel-cobalt-manganese ternary cathode material and its preparation, can solve the problem of low stability of structure and composition electrochemical performance, slow solid-phase diffusion, and difficulty in uniform mixing and other problems, to achieve the effect of low requirements for equipment and reaction conditions, excellent electrochemical performance and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

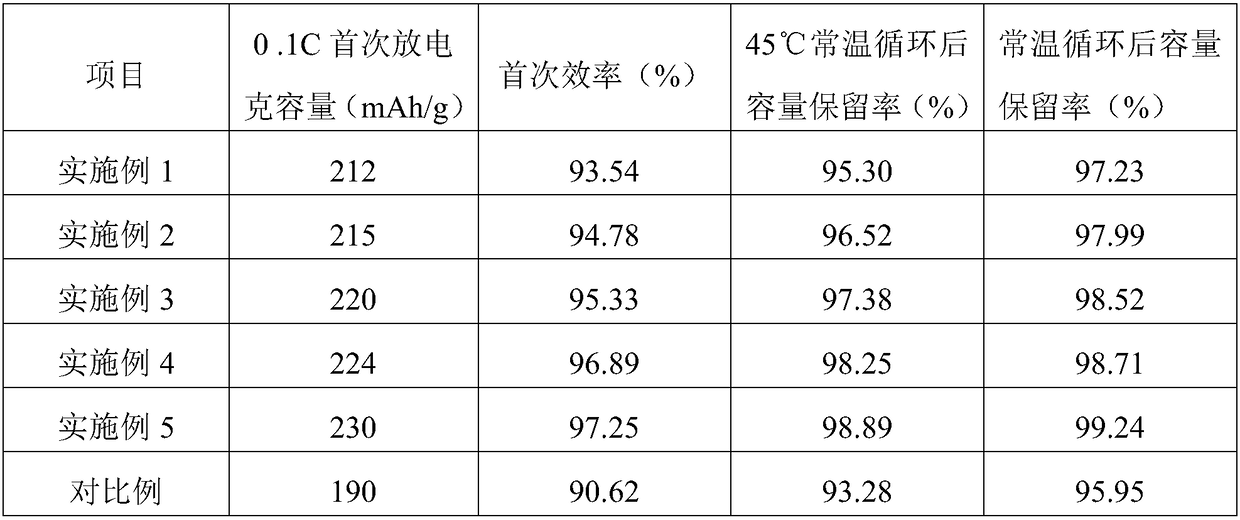

Examples

Embodiment 1

[0023] A method for preparing a modified nickel-cobalt-manganese ternary positive electrode material, comprising the steps of:

[0024] 1) Add cobalt sulfate, manganese sulfate, nickel sulfate, lithium carbonate, and tetraethylamine tetrafluoroborate into citric acid to make 0.5mol L -1 Then the solution is spray-dried to finally obtain precursor particles that are uniformly mixed at the molecular level; the precursor is heated at room temperature at 4°C / min to 750°C, and then kept at this temperature for 10-15h and then naturally cooled ; to be cooled to room temperature, the product is ground, and a 200-mesh sieve is obtained to obtain modified nickel-cobalt-manganese; the cobalt sulfate, manganese sulfate, nickel sulfate, lithium carbonate, and the mol ratio of tetraethylamine tetrafluoroborate are 0.2:0.2:0.6 :1:0.02;

[0025] 2) Add 20 g of the modified nickel-cobalt-manganese prepared in step 1) into 50 g of citric acid aqueous solution with a mass fraction of 20%, and ...

Embodiment 2

[0029] A method for preparing a modified nickel-cobalt-manganese ternary positive electrode material, comprising the steps of:

[0030] 1) Add cobalt nitrate, manganese nitrate, nickel nitrate, lithium acetate, and tetraethylamine tetrafluoroborate into citric acid to make 0.55mol L -1 solution, and then the solution was spray-dried to obtain precursor particles uniformly mixed at the molecular level; the precursor was heated at room temperature at 5 °C / min to 780 °C, and then kept at this temperature for 12 hours and then naturally cooled; Cool to room temperature, grind the product, and pass through a 250-mesh sieve to obtain modified nickel-cobalt-manganese; the molar ratio of cobalt nitrate, manganese nitrate, nickel nitrate, lithium acetate, and tetraethylamine tetrafluoroborate is 0.2:0.2:0.6:1 :0.02;

[0031] 2) Add 23 g of the modified nickel-cobalt-manganese prepared in step 1) into 65 g of citric acid aqueous solution with a mass fraction of 23%, and then add 1.5 g ...

Embodiment 3

[0035] A method for preparing a modified nickel-cobalt-manganese ternary positive electrode material, comprising the steps of:

[0036] 1) Add cobalt chloride, manganese chloride, nickel chloride, lithium chloride, and tetraethylamine tetrafluoroborate to citric acid to make 0.58mol L -1 Then the solution was spray-dried to finally obtain precursor particles mixed uniformly at the molecular level; the precursor was heated at room temperature at 6 °C / min to 800 °C, and then kept at this temperature for 13 hours and then naturally cooled; Cool to room temperature, grind the product, and pass through a 300-mesh sieve to obtain modified nickel-cobalt-manganese; the molar ratio of cobalt chloride, manganese chloride, nickel chloride, lithium chloride, and tetraethylamine tetrafluoroborate is 0.2:0.2 :0.6:1:0.02;

[0037] 2) Add 27 g of the modified nickel-cobalt-manganese prepared in step 1) into 85 g of citric acid aqueous solution with a mass fraction of 26%, and then add 2 g of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com