An application of litmus as a dielectric layer of memristor devices

A memristive device and dielectric layer technology, applied in electrical components and other directions, can solve the problems of high price, complex process, high preparation cost, etc., and achieve excellent performance, low manufacturing cost, good memristive effect and capacitance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose of the present invention, technical solutions and advantages clearer, the present invention will be described in further detail below in conjunction with accompanying drawing:

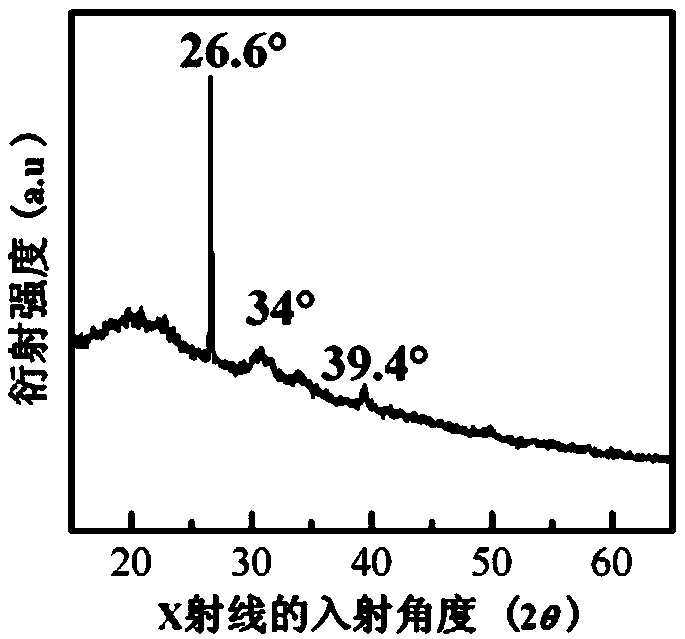

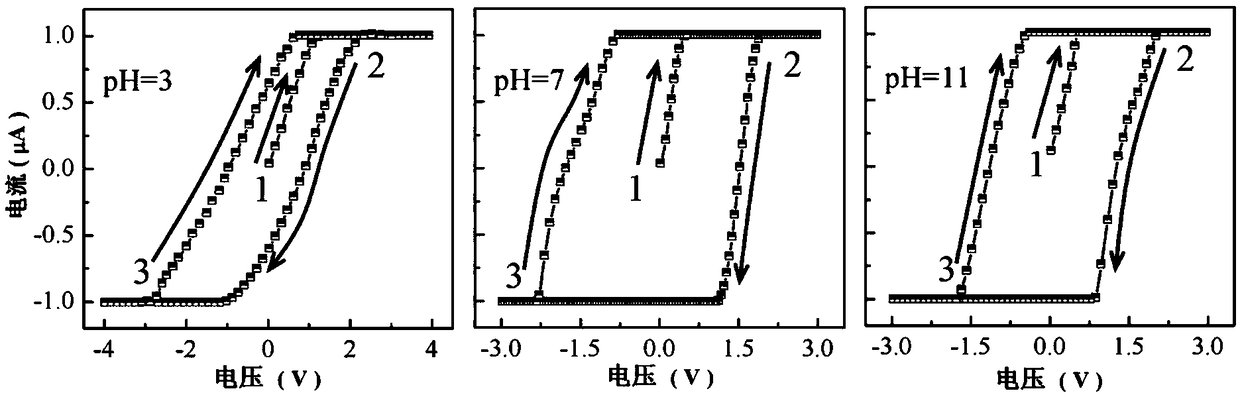

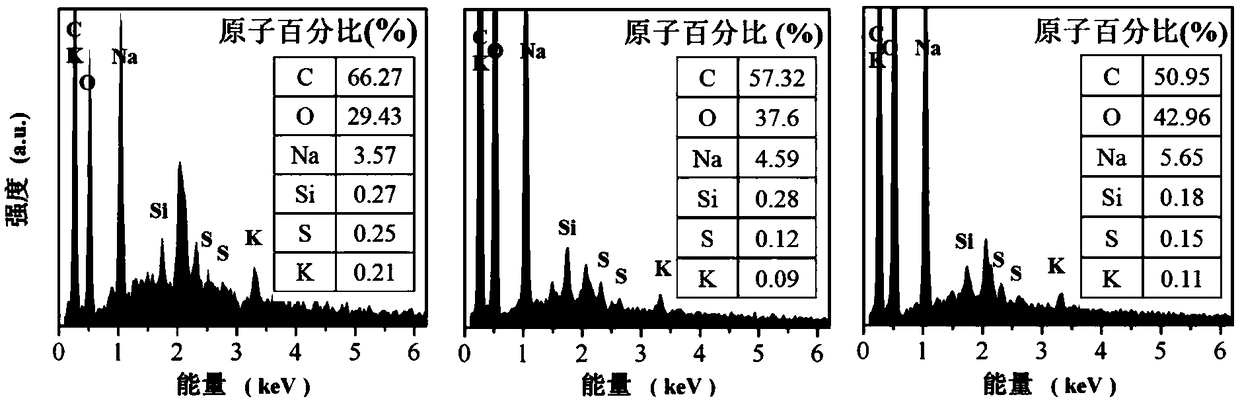

[0028] The present invention will be described in detail below with reference to the accompanying drawings: an application of litmus as a dielectric layer of a memristive device, which specifically includes the following steps:

[0029] Step 1, the extracted litmus is cleaned and dried in a drying box for subsequent use;

[0030] Step 2, crushing the dried litmus, grinding, filtering through a sieve to obtain micron-sized litmus powder, and storing in a dry environment;

[0031] Step 3, using deionized water to dilute 0.03ml of 37% concentrated hydrochloric acid (HCl) solution with a density of 1.19g / ml to obtain a reagent with a total volume of 1L and a pH value of 0.001mol / L, and then 0.04g sodium hydroxide (NaOH) solid is dissolved and diluted with deionized wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com