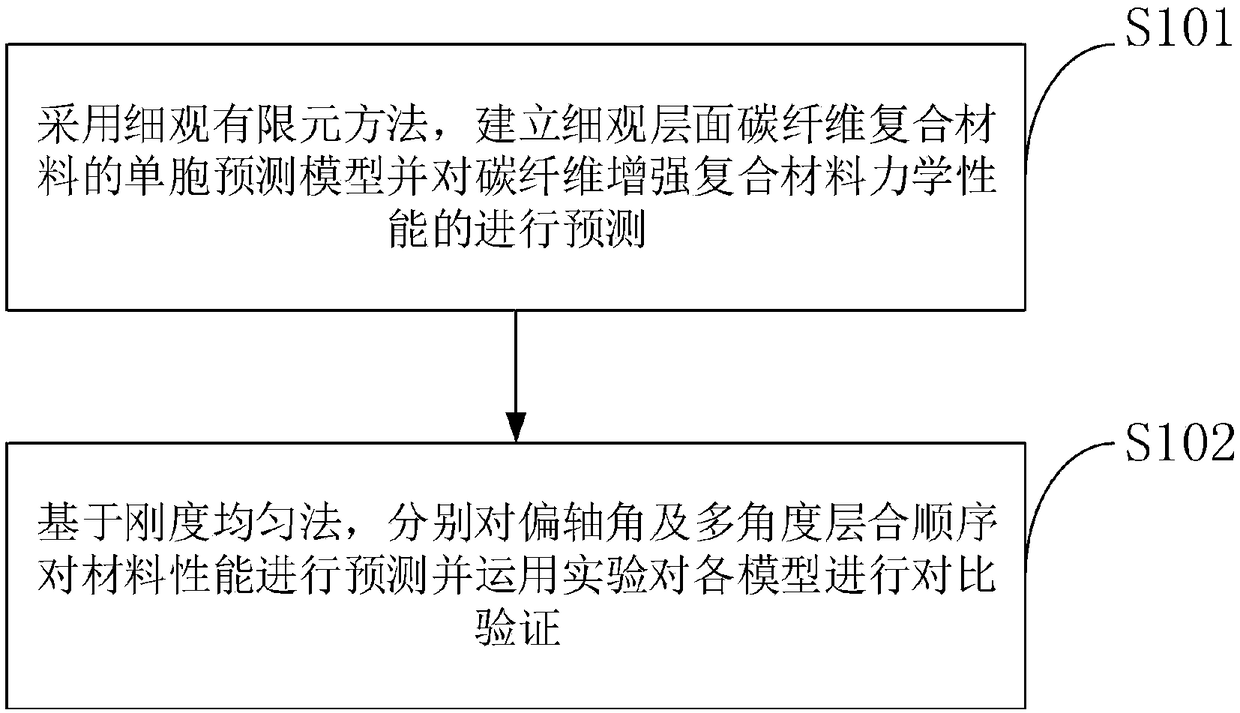

Carbon fiber reinforced composite material mechanical performance prediction method based on cross-scale simulation

A technology for reinforced composite materials and performance prediction, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve bottlenecks in the prediction of parameters such as transverse elastic modulus and shear modulus, and multi-directional composite structures Problems such as complex calculation process, scholar modeling, network division, heavy calculation workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0093] Performance Prediction of Unidirectional Composite Laminates

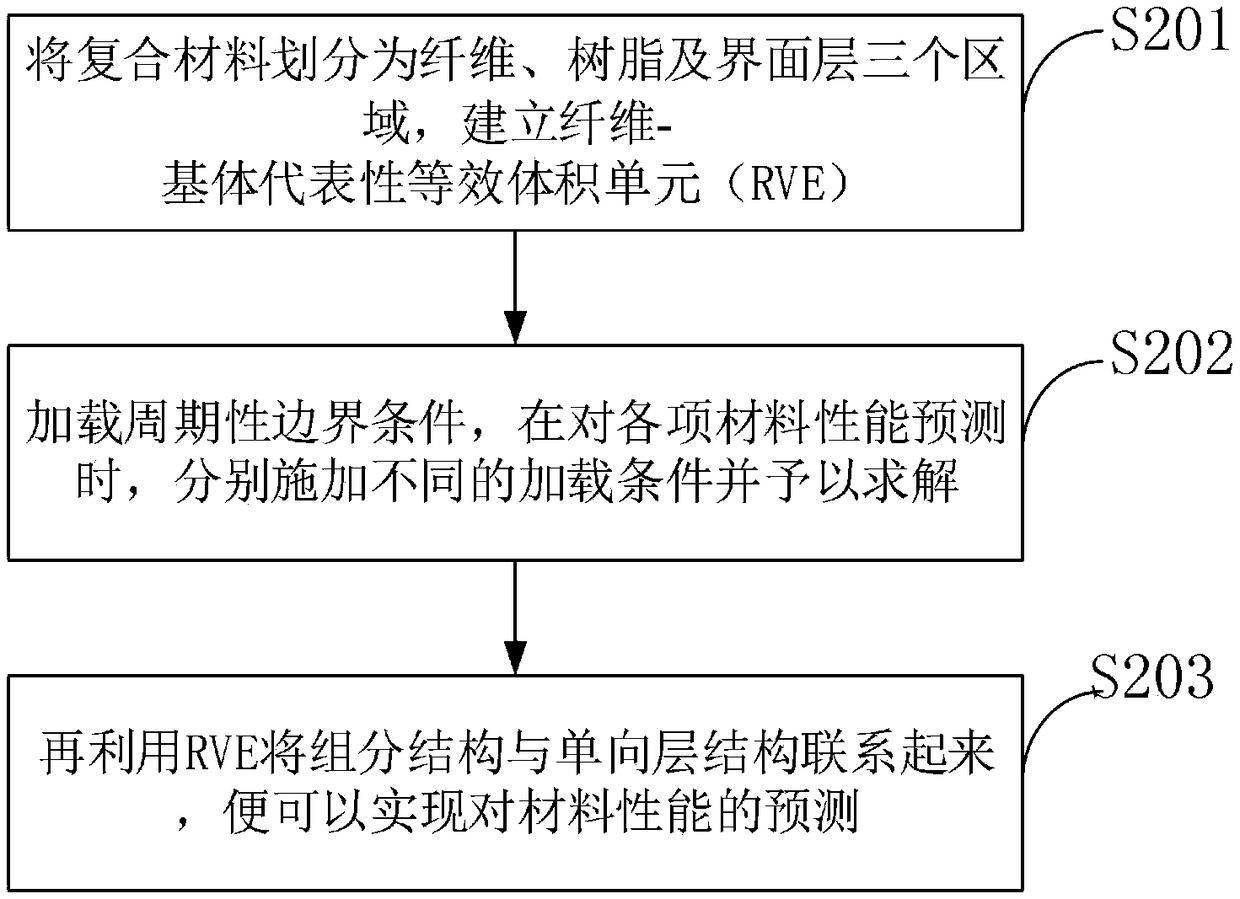

[0094] 1.1 Representative Volume Element (RVE)

[0095] Unidirectional carbon fiber reinforced composite materials are mainly composed of fibers, matrix and interface. In order to realize the modeling and solution of materials, it is necessary to idealize the composite materials at the structural level. Assuming that the composite material is intact, the fiber and the matrix are perfectly combined, and the voids and initial microcracks generated during the preparation are ignored. The fiber is a transversely isotropic material, and the matrix is an isotropic material. Due to the randomness of the fiber arrangement in the actual structure, as shown in 4(a), in the modeling process, the fiber arrangement is generally simplified to a uniform distribution ( Figure 4 (b)) and staggered distribution ( Figure 4 (c)), since the staggered arrangement form is closer to the random distribution of fibers, square a...

Embodiment 2

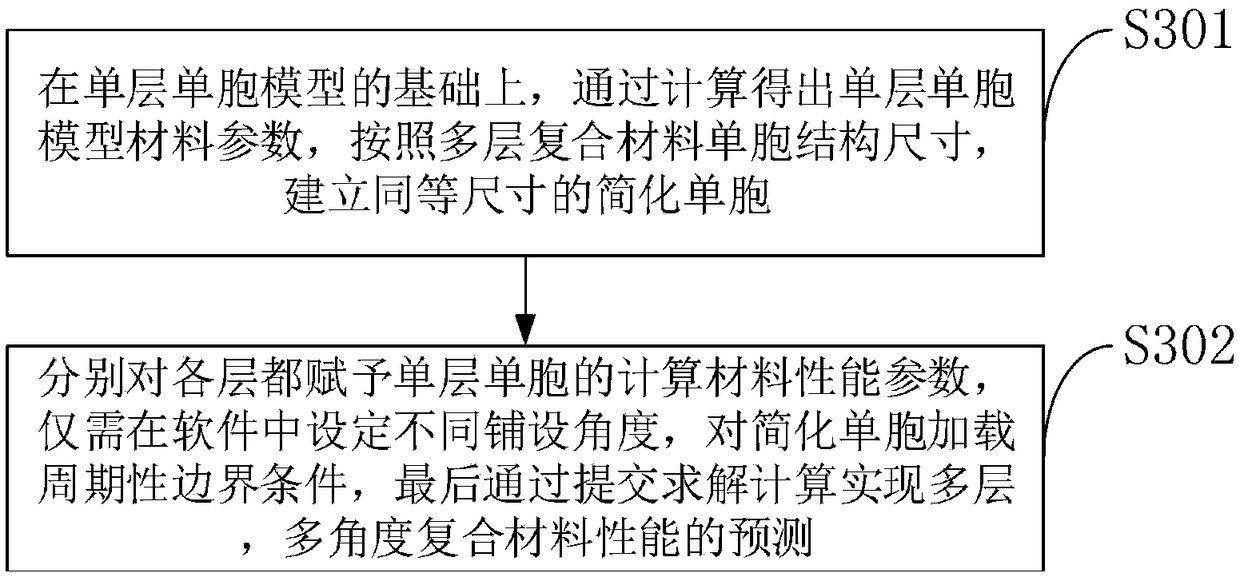

[0123] 2.1 Prediction of mechanical properties of multi-directional composite materials

[0124] Since the preparation process of the multi-angle composite laminate is to lay the single-layer prepreg according to a certain angle, under the action of high temperature and high pressure, each layer of prepreg is bonded, and it becomes a whole by cooling and solidification. Structural components, and the interlacing between the fibers of each layer of prepreg keeps it in its original state under heating, cooling, and solidification (regardless of the fracture during fiber preparation), and there is no mutual embedding between the fiber bundles , therefore, the multi-angle laminate unit cells are modeled in a uniform arrangement. In the single-layer fiber bundle unit cell model, the staggered arrangement of fiber bundles is considered in order to be closer to the random distribution of fibers. The unit cell model adopts a rectangular structure. The interlacing effect of the impreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com