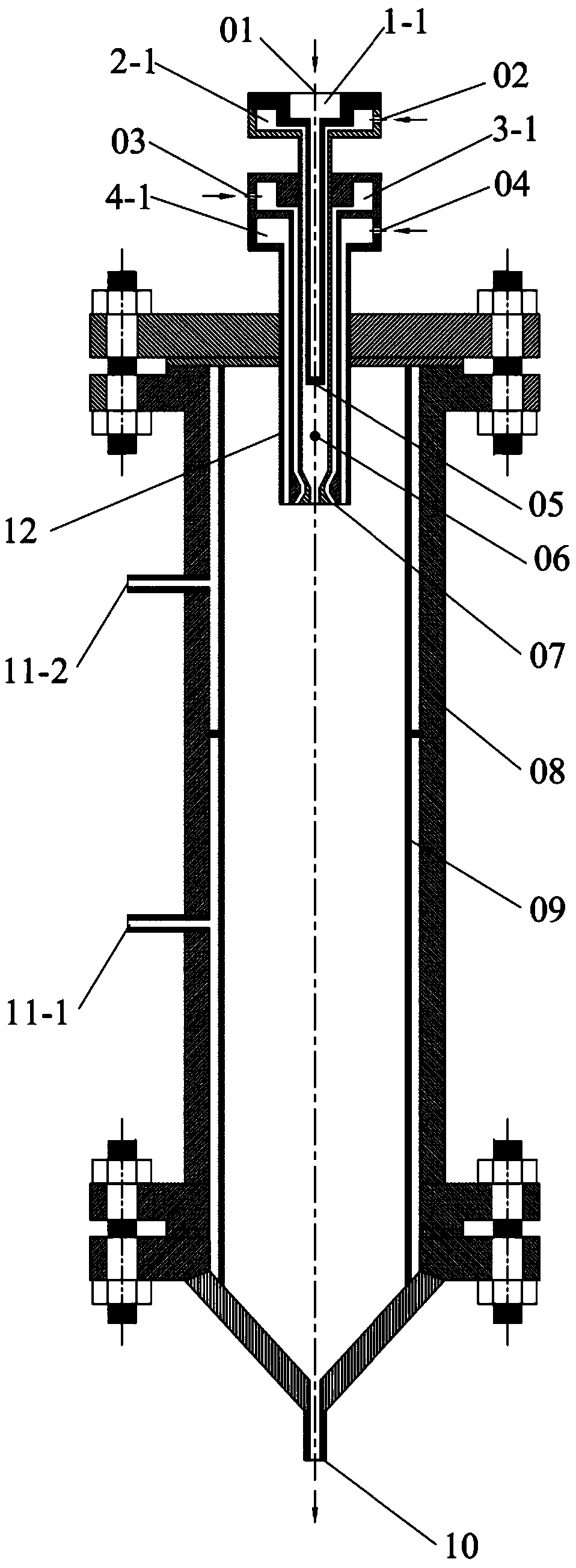

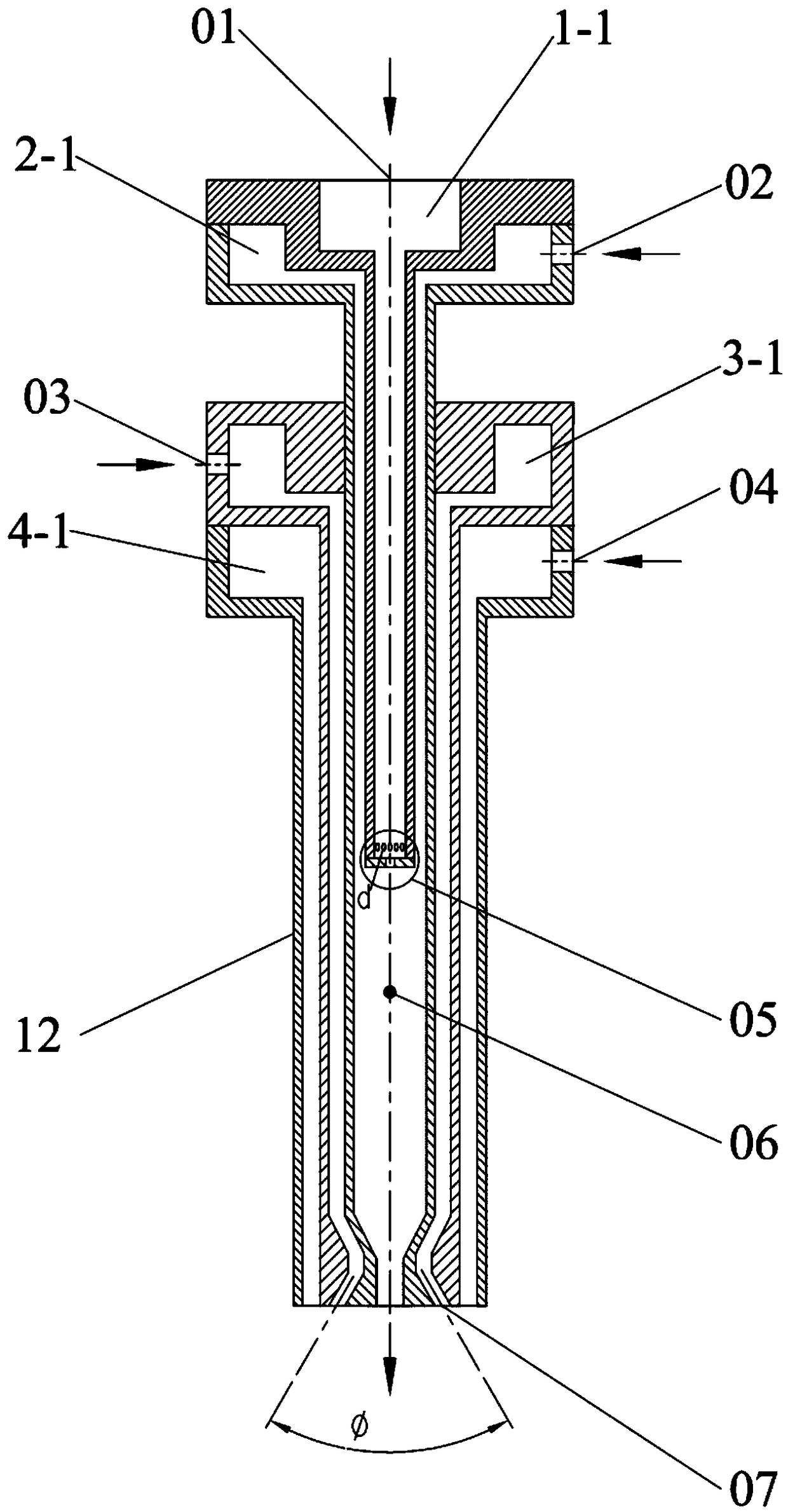

Gas-liquid mixing device for supercritical hydrothermal combustion reactor and application thereof

A technology of supercritical water and supercritical water oxidation, which is applied in the direction of combustion methods, liquid fuel supply/distribution, etc., can solve problems such as carbon deposition, coking and salt deposition, safety accidents, heat transfer deterioration, etc., and achieve saving Equipment investment, reducing high temperature and high pressure heat exchangers, and increasing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

[0051] Experimental example using the supercritical water oxidation reactor of the present invention to treat high-concentration organic wastewater

[0052] The COD value of high-concentration organic wastewater to be treated is 50000-70000mg / L,

[0053] The inlet temperature of the wastewater is 20 degrees Celsius

[0054] The liquid fuel used is methanol with a mass fraction of 8% to 20%.

[0055] The oxidizing agent is oxygen,

[0056] The methanol preheating temperature is 300-400 degrees centigrade and the peroxygen coefficient is 1.5-2.5.

[0057] The feed material (sewage) is preheated through the outer wall of the combustion chamber (06), and after being heated to a supercritical state by a supercritical hydrothermal combustion flame, a supercritical water oxidation reaction occurs in the (08) supercritical water oxidation reactor. The oxidizing agent entering by the first oxidizing agent inlet (02) is pure oxygen (the concentration of oxygen is higher than 99%), an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com