A method for surface modification of insulating braided material

A woven material and surface modification technology, used in electrolytic inorganic material coating, textile and papermaking, fiber processing, etc., can solve the problems of inability to uniformly process the surface of the material, burn the material surface, limit the application prospect, etc., to achieve a large area Continuous processing, low cost, good coating uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for surface modification of an insulating material, the method steps are as follows:

[0029] Step 1. Weigh AlCl 3 , adding deionized water to prepare AlCl with a concentration of 60g / L 3 solution and pour it into the reaction vessel.

[0030] Step 2: Introduce a copper rod into the reaction vessel as the cathode and a graphite plate as the anode, connect a high-frequency DC power supply and apply a voltage of 190V between the cathode and the anode to form a uniform and stable cathode plasma arc area at the cathode.

[0031] Step 3. Pass the high silica fiber braided material (plain weave cloth woven with A-type quartz yarn, produced by Hubei Feilihua Quartz Glass Co., Ltd.) continuously through the cathode plasma arc described in step 2 at a speed of 0.1m / s area, the distance between the insulating braided material and the cathode material is about 40 mm, and the surface modification treatment of the high-silica fiber braided material is realized, and alumin...

Embodiment 2

[0039] A method for surface modification of an insulating braided material, the steps of the method are as follows:

[0040] Step 1. Weigh AlCl 3 , adding deionized water to prepare AlCl with a concentration of 30g / L 3 solution and pour it into the reaction vessel.

[0041] Step 2: Introduce tungsten wire into the reaction vessel as the cathode and platinum as the anode, turn on the high-frequency DC power supply and apply a voltage of 240V between the cathode and the anode to form a uniform and stable cathode plasma arc area on the cathode.

[0042] Step 3. Pass the PE fiber flexible woven material (white PE woven cloth, produced by Shandong Weifang Haoyuan Plastic Knitting Factory) at a speed of 0.6m / s continuously through the cathode plasma arc area described in step 2, and insulate the woven material from the cathode The distance between the materials is about 15mm to realize the surface modification treatment of the PE fiber flexible braided material, and deposit alumin...

Embodiment 3

[0050] A method for surface modification of an insulating braided material, the steps of the method are as follows:

[0051]Step 1. Weigh NaAlO 2 , adding deionized water to prepare NaAlO with a concentration of 80g / L 2 solution and pour it into the reaction vessel.

[0052] Step 2: Introduce a copper rod into the reaction vessel as the cathode and a graphite plate as the anode, connect a high-frequency DC power supply and apply a voltage of 400V between the cathode and the anode to form a uniform and stable cathode plasma arc area at the cathode.

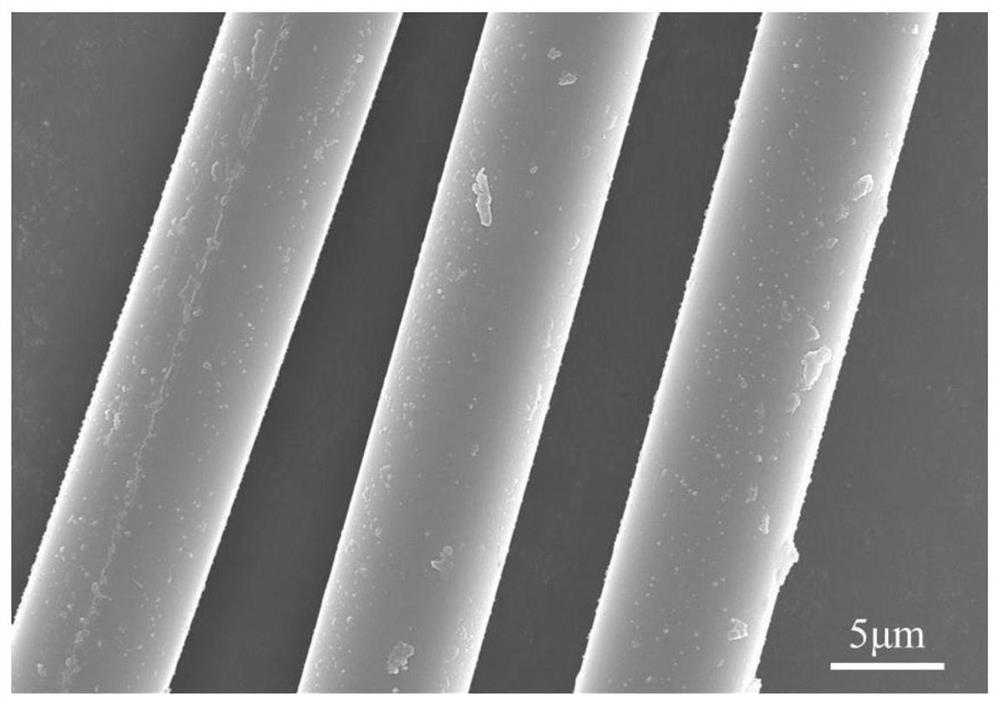

[0053] Step 3. Pass the braided quartz fiber material (quartz fiber cloth with a specification of 5 μm, produced by Henan Shenjiu Composite Material Co., Ltd.) at a speed of 0.02 m / s continuously through the cathode plasma arc area described in step 2, and insulate the braided material from the cathode The distance between the materials is about 10mm, and the surface modification treatment of the quartz fiber braided material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com