A method for regulating and preparing in-situ binary nanoparticle-reinforced aluminum matrix composites

A composite material and nanoparticle technology, which is applied in the field of in-situ binary nanoparticle reinforced aluminum matrix composite materials, can solve the problems of low yield of binary nanoparticles, limited effective depth of melt, and difficulty in particles reaching nanometer size. , to achieve the effect of inhibiting the tendency of agglomeration, inhibiting further growth and finer particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

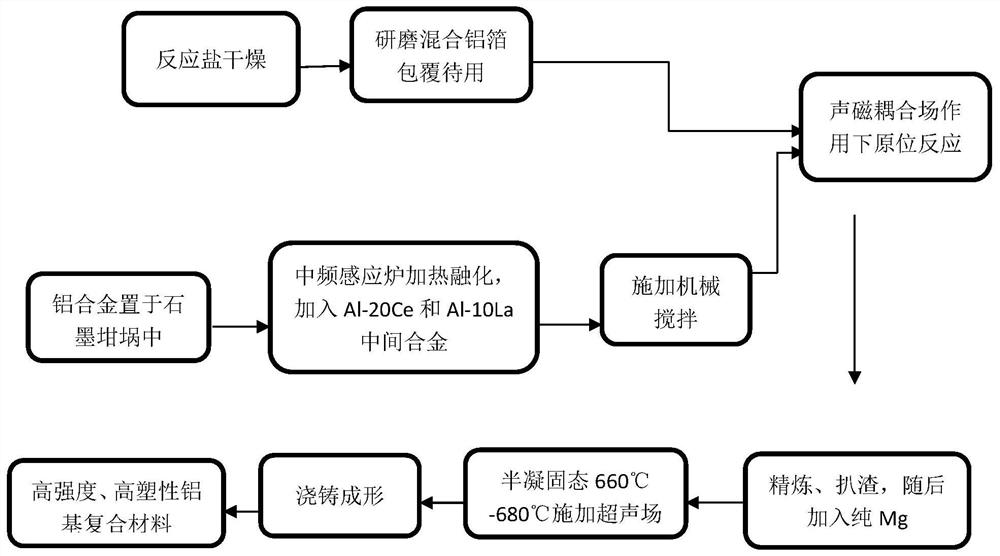

Method used

Image

Examples

Embodiment 1

[0036] Prepared Al 2 o 3 and ZrB 2 A high-strength, high-plastic aluminum matrix composite material with a particle volume fraction of 3%.

[0037] This reaction uses industrial grade borax Na 2 B 4 o 7 and K 2 ZrF 6 The powder is a reactant, which is dried in a drying oven to remove crystal water at a temperature of 200°C for 120 minutes. The dried powder is ground to 200 mesh fine powder on the ball mill, then according to the mass ratio Na 2 B 4 o 7 :K 2 ZrF 6 =38:65, weigh Na 2 B 4 o 7 Powder 164.7g, K 2 ZrF 6 Powder 256.4g. Mix well and wrap with aluminum foil for later use. Weigh 930.5g of 6111 aluminum alloy. The 6111 aluminum alloy is melted in an intermediate frequency orange pot induction furnace. After the temperature rises to 760 ° C, 27.9g of Al-10Ce master alloy and 74.4g of Al-10La master alloy are added, and mechanical stirring is applied. The graphite rotor speed is 200r / min , the mechanical stirring time is 3min. Then keep warm for 5min. ...

Embodiment 2

[0040] Industrial grade borax Na 2 B 4 o 7 and K 2 ZrF 6 The powder is a reactant, according to the volume fraction of 1.5% nanometer (Al 2 o 3 +ZrB 2 ) binary nanoparticles for stoichiometric proportioning. It was dried in a drying oven to remove crystal water, the drying temperature was 150° C., and the drying time was 150 minutes. The dried powder is ground to 200 mesh fine powder on the ball mill, then according to the mass ratio Na 2 B 4 o 7 :K 2 ZrF 6 =38:65, weigh Na 2 B 4 o 7 Powder 123.2g, K 2 ZrF 6 Powder 191.8g. Mix well and wrap with aluminum foil for later use. Weigh 1382.7g of 6111 aluminum alloy. The 6111 aluminum alloy is melted in an intermediate frequency orange pot induction furnace. After the temperature rises to 760°C, add 41.5g Al-10Ce master alloy and 110.6g Al-10La master alloy, apply mechanical stirring, and the graphite rotor speed is 250r / min , mechanical stirring time is 5min, followed by 5min insulation. After the temperature r...

Embodiment 3

[0043] Prepared Al 2 o 3 and ZrB 2 A high-strength, high-plastic aluminum matrix composite material with a particle volume fraction of 5%.

[0044] This reaction uses industrial grade borax Na 2 B 4 o 7 and K 2 ZrF 6The powder is the reactant, and it is dried in a drying oven to remove crystal water at a temperature of 200°C for 180 minutes. The dried powder is ground to 200 mesh fine powder on the ball mill, then according to the mass ratio Na 2 B 4 o 7 :K 2 ZrF 6 =38:65, weigh Na 2 B 4 o 7 Powder 269.5g, K 2 ZrF 6 Powder 419.4g. Mix well and wrap with aluminum foil for later use. Weigh 921.5g of 6111 aluminum alloy. The 6111 aluminum alloy was melted in an intermediate frequency orange pot-type induction furnace. After the temperature rose to 780°C, 27.6g of Al-10Ce master alloy and 73.7g of Al-10La master alloy were added, and mechanical stirring was applied. The graphite rotor speed was 300r / min, and the mechanical stirring time is 5 min. Then keep wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com