Polyimide matting powder and preparation method thereof, polyimide film containing the matting powder and preparation method thereof

A technology of polyimide matting powder and polyamic acid resin, which is applied in the field of polyimide film, can solve the problems of high energy consumption and increased cost of polyimide particles, and achieve low reaction temperature, good mechanical properties and The effect of low electric strength and production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

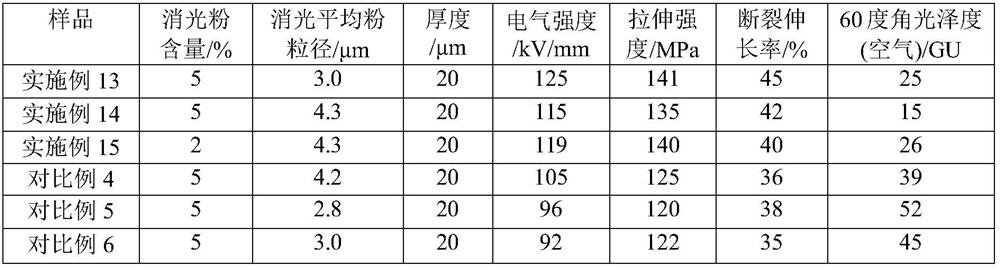

Examples

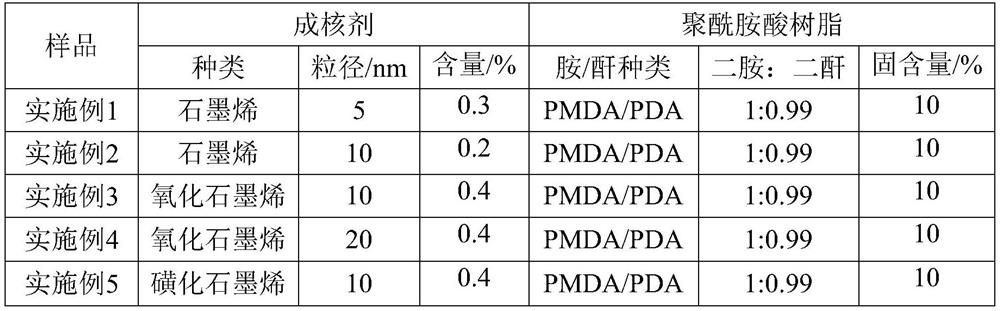

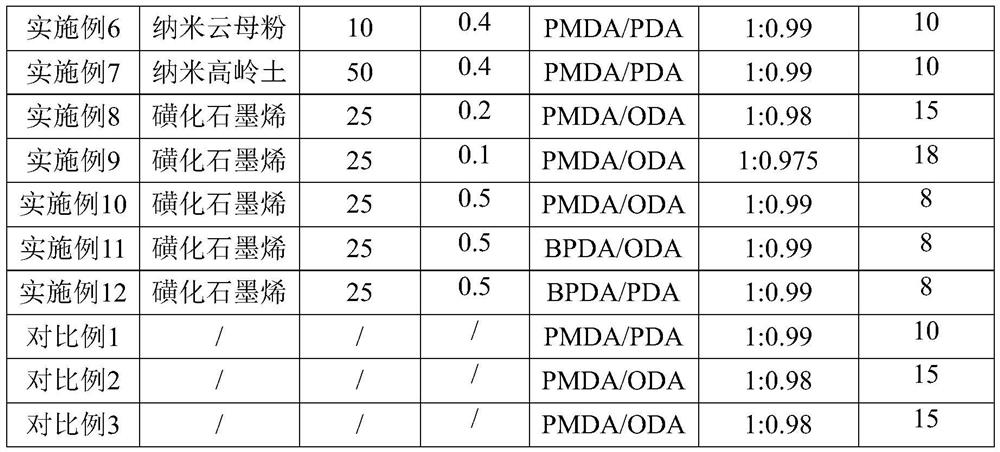

Embodiment 1

[0030] 1) Add 1350 g of DMAc and 0.460 mol of PDA to a reaction vessel with a capacity of 2000 ml of reflux condensing device, dissolve for 40 minutes, add 0.455 mol of PMDA in batches, react at room temperature for 3 hours, and heat the system during stirring to 100°C, and react for 1 hour to obtain a homogenized polyamic acid resin solution, which is set aside;

[0031] 2) When preparing the above-mentioned resin solution, 0.45 g of graphene with an average particle diameter of 5 nm was dissolved in 50 g of DMAc, and ultrasonically dispersed to obtain a nucleating agent dispersion for subsequent use;

[0032] 3) Add the nucleating agent dispersion liquid obtained in step 2) to the homogenized polyamic acid resin solution obtained in step 1), continue to stir and heat to 150 ° C for 4 hours, and the polyimide particles are precipitated, stop After heating and stirring, after cooling to room temperature, collect the polyimide particles, wash with ethanol, filter, collect the f...

Embodiment 2

[0034] Repeat Example 1, the difference is:

[0035] In steps 1) and 2), the aprotic polar solvent is changed to N-methyl-2-pyrrolidone (NMP);

[0036] Step 2) in, nucleating agent adopts the graphene that average particle diameter is 10nm, and weight is 0.3g;

[0037] In step 3), the reaction temperature is 180° C., and the reaction time is 1 h.

Embodiment 3

[0039] Repeat Example 1, the difference is:

[0040] In step 2), the nucleating agent adopts graphene oxide with an average particle diameter of 10 nm and a weight of 0.6 g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com