High-strength alkali activated gel material applicable to special environments

A gel material, high-strength technology, applied in the field of building materials, can solve problems such as potential safety hazards, and achieve the effect of enhancing compressive strength, good bonding effect and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

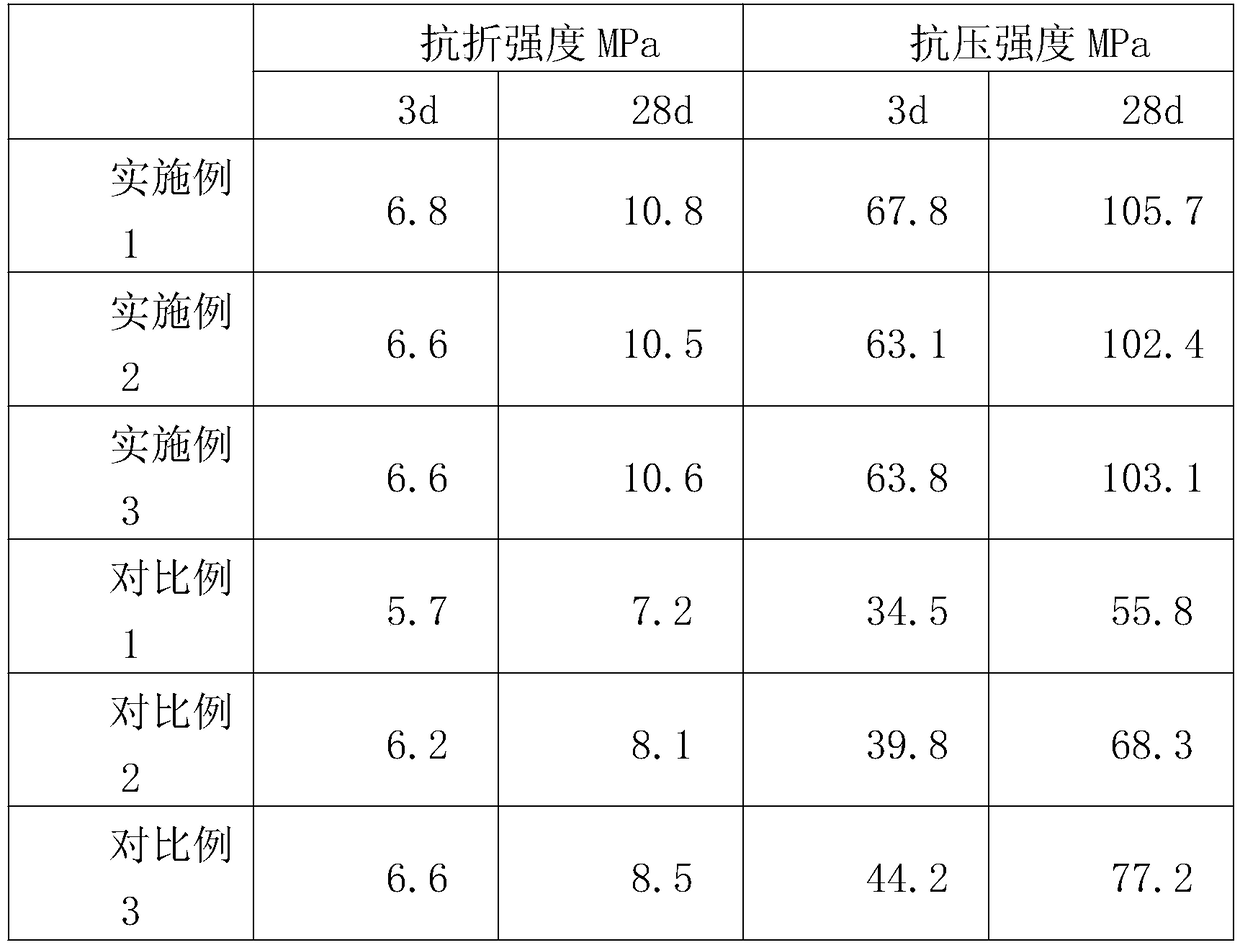

Examples

Embodiment 1

[0035] A high-strength alkali-activated gel material applicable to special environments, consisting of the following components by weight percentage:

[0036] Fly Ash 42%

[0037] Iron slag 9%

[0038] Retarder 3.5%

[0039] Polymer rubber powder 2%

[0040] Iron, cesium hydrotalcite 0.15%

[0041] Base activator balance.

[0042] The iron slag contains CaO, SiO 2 、Al 2 o 3 , MgO, MnO, Fe 2 o 3 and other ingredients, wherein the content of iron is 2.5%.

[0043] Described alkali activator is liquid water glass (Na 2 O nSiO 2 ); Described liquid water glass (Na 2 O nSiO 2 ) modulus n is 1.8.

[0044] The preparation method of described iron, cesium hydrotalcite, comprises the following steps:

[0045] Step 1: dissolving sodium metaaluminate and sodium hydroxide in deionized water to prepare solution A;

[0046] Step 2: dissolving ferric chloride in deionized water to prepare solution B;

[0047] Step 3: dissolving cesium oxide with dilute hydrochloric acid and ...

Embodiment 2

[0058] A high-strength alkali-activated gel material applicable to special environments, consisting of the following components by weight percentage:

[0059] Fly Ash 35%

[0060] Iron slag 12%

[0061] Retarder 2%

[0062]Polymer rubber powder 5%

[0063] Iron, cesium hydrotalcite 0.1%

[0064] Base activator balance.

[0065] The iron slag contains CaO, SiO 2 、Al 2 o 3 , MgO, MnO, Fe 2 o 3 and other ingredients, wherein the iron content is 2.1%.

[0066] Described alkali activator is liquid water glass (Na 2 O nSiO 2 ).

[0067] The liquid water glass (Na 2 O nSiO 2 ) modulus n is 2.0.

[0068] The preparation method of described iron, cesium hydrotalcite, comprises the following steps:

[0069] Step 1: dissolving sodium metaaluminate and sodium hydroxide in deionized water to prepare solution A;

[0070] Step 2: dissolving ferric chloride in deionized water to prepare solution B;

[0071] Step 3: dissolving cesium oxide with dilute hydrochloric acid and po...

Embodiment 3

[0082] A high-strength alkali-activated gel material applicable to special environments, consisting of the following components by weight percentage:

[0083] Fly Ash 45%

[0084] Iron slag 8%

[0085] Retarder 5%

[0086] Polymer rubber powder 1%

[0087] Iron, cesium hydrotalcite 0.3%

[0088] Base activator balance.

[0089] The iron slag contains CaO, SiO 2 、Al 2 o 3 , MgO, MnO, Fe 2 o 3 and other ingredients, wherein the iron content is not less than 2%.

[0090] Described alkali activator is liquid water glass (Na 2 O nSiO 2 ).

[0091] The liquid water glass (Na 2 O nSiO 2 ) modulus n is 1.6.

[0092] The preparation method of described iron, cesium hydrotalcite, comprises the following steps:

[0093] Step 1: dissolving sodium metaaluminate and sodium hydroxide in deionized water to prepare solution A;

[0094] Step 2: dissolving ferric chloride in deionized water to prepare solution B;

[0095] Step 3: dissolving cesium oxide with dilute hydrochloric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com