Straw/aluminium polychlorid composite water treatment material and preparation method thereof

A polyaluminum chloride, water treatment technology, applied in water/sewage treatment, water/sludge/sewage treatment, flocculation/sedimentation water/sewage treatment, etc. Abundant sources of raw materials, the effect of solving the high concentration of water and aluminum ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

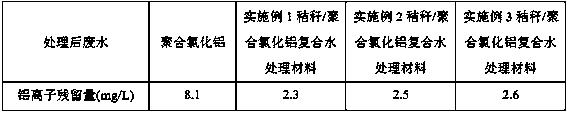

Examples

Embodiment 1

[0023] 1) Put 20g of fly ash in a reaction bottle, add 60 mL of 10wt% hydrochloric acid solution to soak for 5 hours, then add 20wt% sodium hydroxide solution to adjust the pH to 11, filter, and in the obtained filtrate by volume Add 10wt% hydrochloric acid solution at a ratio of 1:1, react at 70°C for 1.5 hours under stirring conditions; filter and separate after the reaction to obtain a filtrate containing aluminum chloride, add 6g of calcium carbonate powder to the obtained filtrate to adjust the basicity , after stirring, filtering, and drying the filtrate, polyaluminum chloride powder is obtained (the undried filtrate can also be directly used as a water purifying agent);

[0024] 2) At room temperature, the rice straw was washed with water to remove soil, dried and crushed, and then added to 5wt% sodium hydroxide solution to prepare a solution with a straw concentration of 2wt%, and then stirred rapidly at 200 r / min. Stir at a slow speed of 120 r / min for 24 hours to obta...

Embodiment 2

[0029] 1) Put 20g of fly ash in the reaction bottle, add 60 mL, 20wt% hydrochloric acid solution to soak for 6 hours, then add 25wt% sodium hydroxide solution to adjust the pH to 12, filter, and in the obtained filtrate according to the volume ratio Add 15wt% hydrochloric acid solution at 1:1, react at 80°C for 1.5 hours under stirring conditions; filter and separate after the reaction to obtain a filtrate containing aluminum chloride, add 7g of calcium carbonate powder to the obtained filtrate to adjust the basicity, After stirring, filtering, and drying the filtrate, polyaluminum chloride powder is obtained (the undried filtrate can also be directly used as a water purifier);

[0030] 2) At room temperature, the rice straw was washed with water to remove soil, dried and crushed, then added to 10wt% sodium hydroxide solution to prepare a solution with a straw concentration of 3wt%, and then stirred rapidly at 230 r / min. Stir at a slow speed of 130 r / min for 24 hours to obtain...

Embodiment 3

[0035] 1) Put 20g of fly ash in a reaction bottle, add 60 mL of 30wt% hydrochloric acid solution to soak for 8 hours, then add 30wt% sodium hydroxide solution to adjust the pH to 13, filter, and in the obtained filtrate by volume Add 10wt% hydrochloric acid solution at a ratio of 1:1 mL, react at 90°C for 1.5 hours under stirring conditions; filter and separate after the reaction to obtain a filtrate containing aluminum chloride, add 8g of calcium carbonate powder to the obtained filtrate to adjust the base degree, after stirring, filtering, and drying the filtrate, polyaluminium chloride powder is obtained (the undried filtrate can also be directly used as a water purifying agent);

[0036] 2) At room temperature, the rice straw was washed with water to remove soil, dried and crushed, then added to 15wt% sodium hydroxide solution to prepare a solution with a straw concentration of 5wt%, and then stirred rapidly at 250 r / min. Stir at a slow speed of 150 r / min for 24 hours to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com