A kind of two-dimensional metal oxide nanosheet and its preparation method

An oxide and nanosheet technology, applied in the field of nanomaterials, can solve the problems of low yield of metal oxide nanosheets, insufficient preparation methods, and harsh reaction conditions, so as to avoid uncontrollable growth and avoid further growth. , the effect of good universality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1. Preparation of magnesium oxide nanosheets

[0029] (1): 0.1 g of layered graphene framework material is added to 10 milliliters of magnesium nitrate solution with a concentration of 1 mol / liter, soaked and filtered to obtain wet layered graphene framework material particles containing magnesium nitrate solution;

[0030] (2): Add the wet-state layered graphene framework material particles obtained in step (1) into 100 ml of sodium hydroxide solution with a concentration of 0.5 mol / liter, and the precipitate is filtered, washed and dried to obtain the graphene framework material / magnesium hydroxide complex;

[0031] (3): The graphene framework material / magnesium hydroxide composite obtained in step (2) was calcined in air at 500° C. for 2 hours to obtain the final magnesium oxide nanosheets.

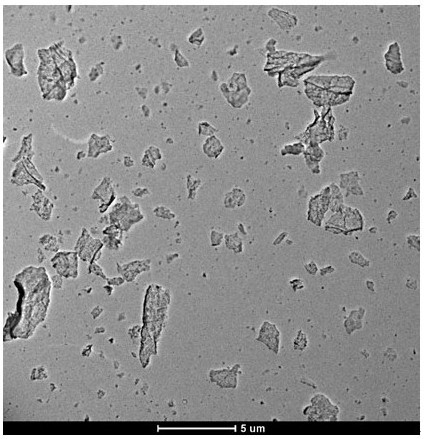

[0032] The characterization results of the obtained magnesium oxide nanosheets are shown in the attached figure 1 .

Embodiment 2

[0033] Embodiment 2. Preparation of titanium dioxide nanosheets

[0034] (1): Add 0.1 g of layered graphene framework material to 10 ml of titanyl sulfate aqueous solution with a concentration of 0.1 mol / liter, soak and filter to obtain wet-state layered graphene framework material particles containing titanyl sulfate solution;

[0035] (2): Add the wet-state layered graphene framework material particles obtained in step (1) into 100 ml of sodium hydroxide solution with a concentration of 1 mol / liter, and the precipitate is filtered, washed and dried to obtain the graphene framework material / titanium hydroxide complex;

[0036] (3): The graphene framework material / titanium hydroxide composite obtained in step (2) was calcined in air at 700° C. for 2 hours to obtain the final titanium dioxide nanosheets.

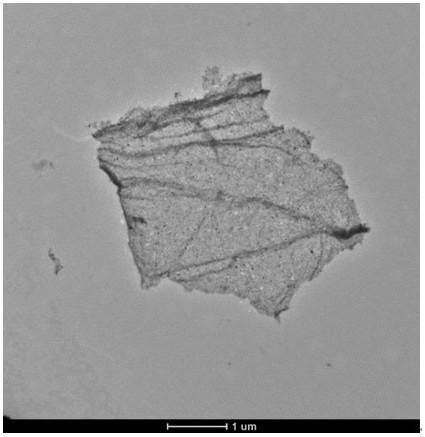

[0037] The characterization results of the obtained titanium dioxide nanosheets are shown in the attached figure 2 .

Embodiment 3

[0038] Embodiment 3. Preparation of ferric oxide nanosheets

[0039] (1): Add 0.1 g of layered graphene frame material to 10 ml of ferric sulfate solution with a concentration of 5 mol / liter, soak and filter to obtain wet layered graphene frame material particles containing ferric sulfate solution;

[0040] (2): Add the wet-state layered graphene framework material particles obtained in step (1) into 100 ml of ammonia solution with a concentration of 1 mol / liter, and the precipitate is filtered, washed and dried to obtain the graphene framework material / hydrogen Iron oxide complex;

[0041] (3): Calcining the graphene framework material / iron hydroxide composite obtained in step (2) at 400° C. in air for 5 hours to obtain the final ferric oxide nanosheets.

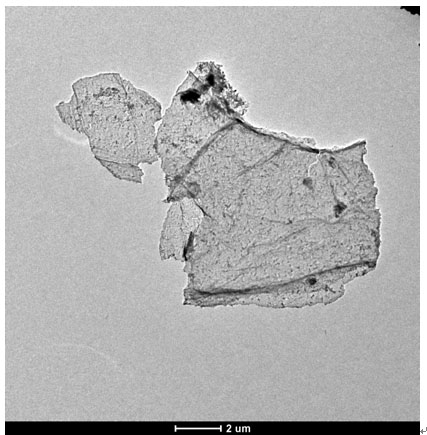

[0042] The characterization results of the obtained ferric oxide nanosheets are shown in the attached image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com