Production system for anti-aging linear low density polyethylene resin

A linear low-density, polyethylene resin technology, applied in the field of polyethylene resin, can solve problems such as affecting the quality of finished products and inability to meet storage requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

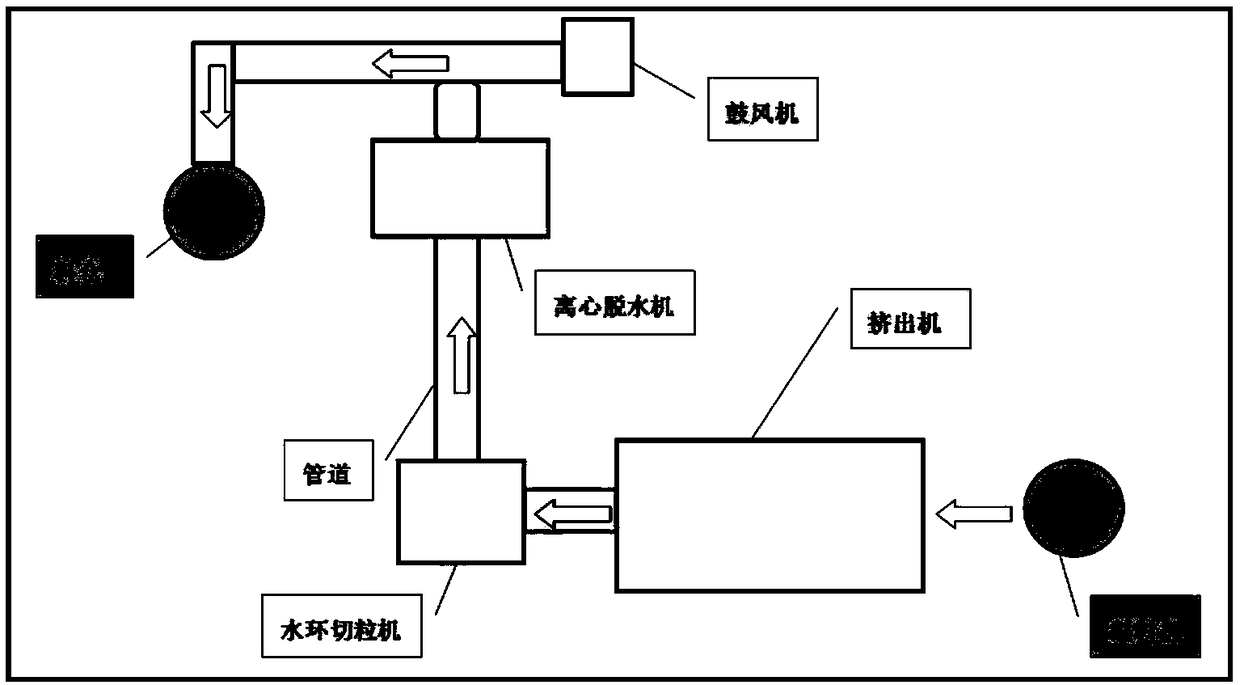

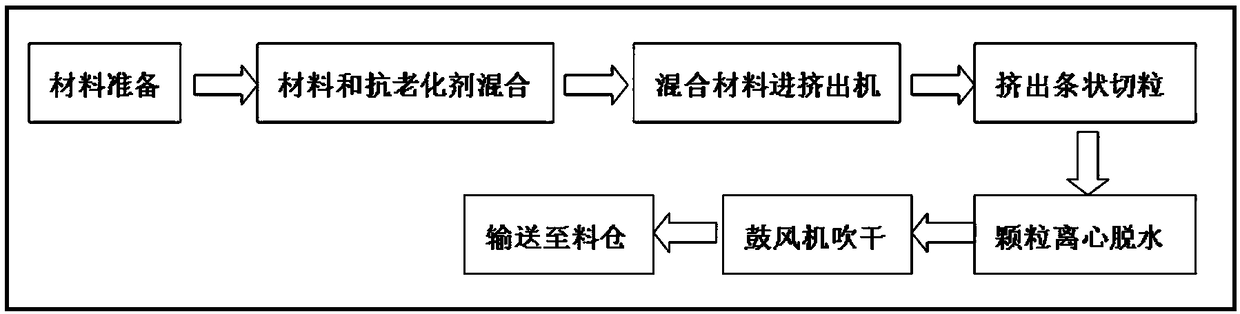

[0028] refer to figure 1 as well as figure 2 , a kind of anti-aging linear low-density polyethylene resin manufacturing method, comprises the following steps:

[0029] S1: take linear low density polyethylene resin, anti-aging agent and pigment;

[0030] S2: Grind the pigment into fine foam, mix it with the anti-aging agent, and stir evenly; then add it to high-density polyethylene resin and mix evenly;

[0031] S3: the section regulation extruder is equipped with the barrel temperature mixed in S2;

[0032] S4: Extrude a linear low-density polyethylene resin in a strip shape.

[0033] The linear low density polyethylene resin model is LL1001 or LL1002.

[0034] The anti-aging agent is one or more of the antioxidant BHT, the antioxidant TNP distearoylthiodipropionate DSTDP, and barium stearate.

[0035] Wherein antioxidant BHT (100g / kg), antioxidant TNP (140g / kg) / distearyl thiodipropionate DSTDP (90g / kg), barium stearate (110g / kg).

[0036] The first section of the barr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com