Production technology of packaging composite film

A production process and composite film technology, which are applied in the directions of devices and coatings for coating liquid on the surface, can solve the problems of the barrier performance of the packaging composite film being difficult to meet the requirements of high-barrier drug packaging, and the complex preparation process of the packaging composite film. Achieve the effect of eliminating the corona step, shortening the working hours, and shortening the soaking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

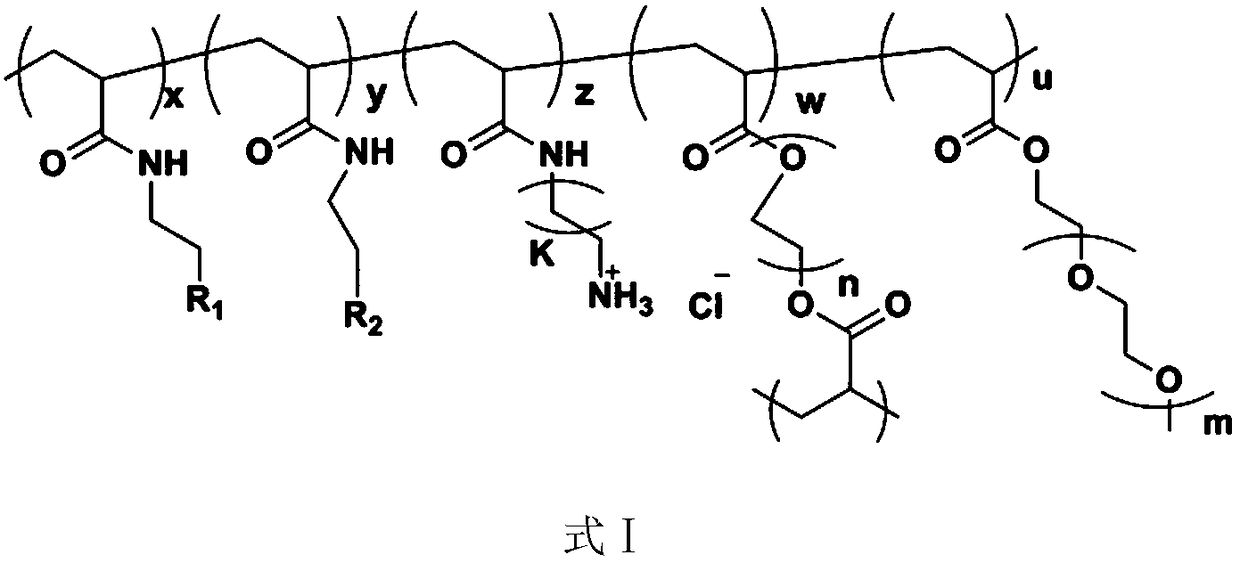

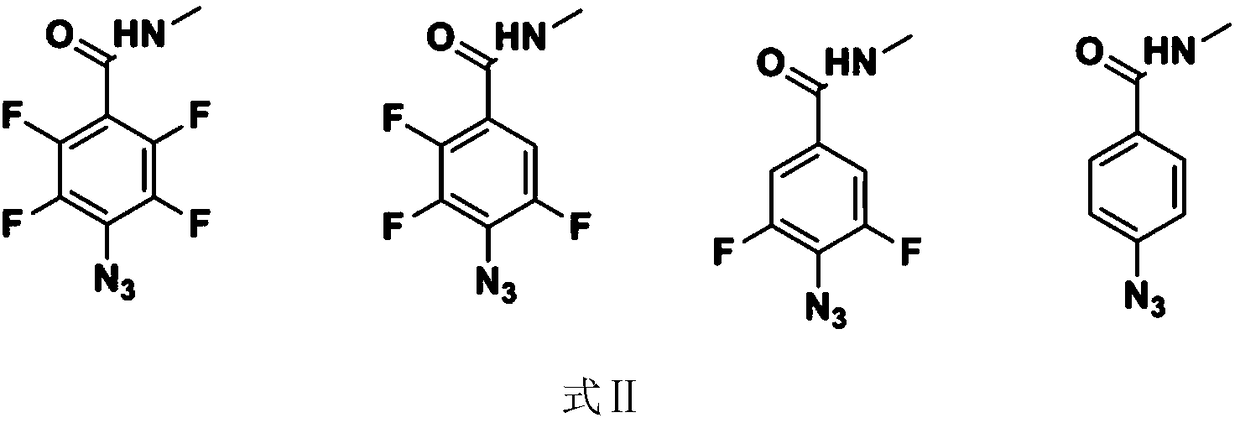

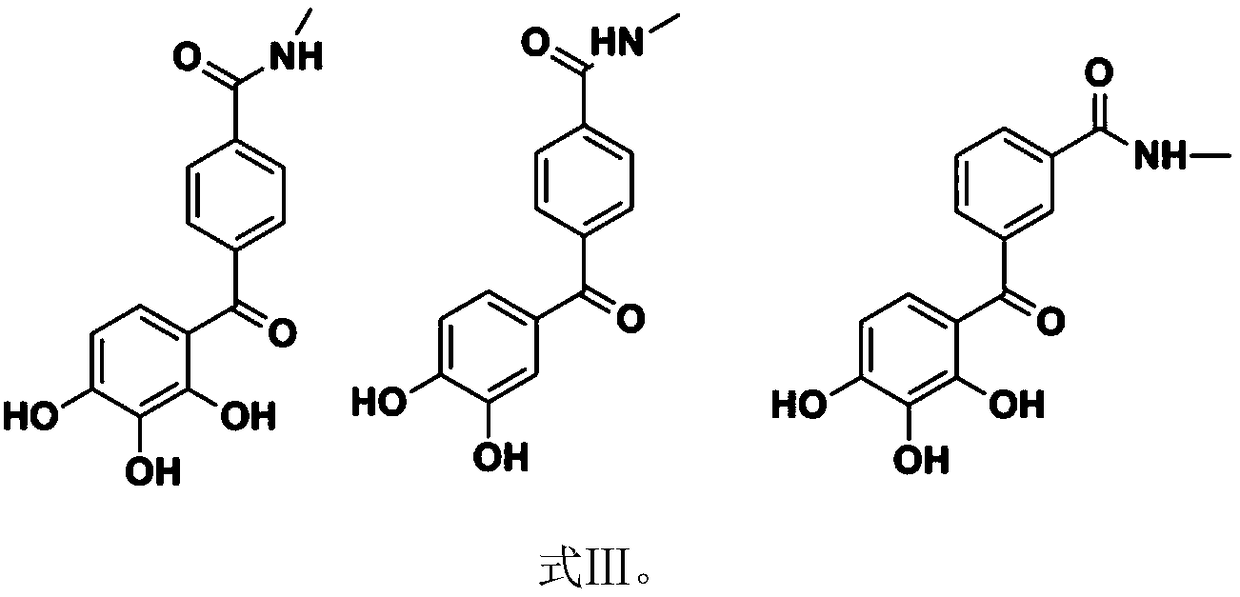

[0071] Preparation of hyperbranched cationic mussel-like polymer P1:

[0072]2,3,4-Trihydroxybenzoyl-isobenzoyl-(2-aminoethyl)acrylamide, N-(2-aminoethyl)(meth)acrylamide hydrochloride, 4-azide 2,3,5,6-tetrafluorobenzoylethylamine (meth)acrylamide, polyethylene glycol methyl ether acrylate (PEGMEA), polyethylene glycol diacrylate (PEGDEA, ethylene glycol The degree of polymerization is 22) and the RAFT reagent is added to the N,N-dimethylformamide solution with the concentration of 0.012M as the initiator 4,4'-azobis(4-cyanovaleric acid). Among them, the degree of polymerization of ethylene glycol in PEGMEA is 15, the degree of polymerization of ethylene glycol in PEGDEA is 22, 4,4'-azobis(4-cyanovaleric acid), RAFT reagent and all monomers involved in polymerization The molar ratio of the first reaction mixture is 1:2:100. 2,3,4-trihydroxybenzoyl-isobenzoyl-(2-aminoethyl)acrylamide:N-(2-aminoethyl) (Meth)acrylamide hydrochloride: 4-azido-2,3,5,6-tetrafluorophenacylethylamin...

Embodiment 2

[0079] Preparation of hyperbranched cationic mussel-like polymer P2:

[0080] 2,3,4-trihydroxybenzoyl p-benzamide ethyl (meth)acrylamide hydrochloride, N-(3-aminopropyl) (meth)acrylamide hydrochloride, 4- Nitro-2,3,5,6-tetrafluorobenzoylethylamine (meth)acrylamide, polyethylene glycol methyl ether acrylate (PEGMEA), polyethylene glycol diacrylate (PEGDEA) and RAFT The reagent is added to the N,N-dimethylformamide solution with the concentration of 0.012M of the initiator 2,2'-azobis(2-methylpropionitrile). Among them, the degree of polymerization of ethylene glycol in PEGMEA is 45, the degree of polymerization of ethylene glycol in PEGDEA is 10, 2,2'-azobis(2-methylpropionitrile), RAFT reagent and all monomers participating in polymerization The molar ratio of the first reaction mixture is 1:2:100. 2,3,4-trihydroxybenzoylbenzamide ethyl (meth)acrylamide hydrochloride: N-(3-aminopropyl) (Meth)acrylamide hydrochloride: 4-azido-2,3,5,6-tetrafluorophenacylethylamine (meth)acryla...

Embodiment 3

[0088] Preparation of hyperbranched cationic mussel-like polymer P3:

[0089] 2,3-Dihydroxybenzoylbenzoate amine ethyl (meth)acrylamide hydrochloride, N-(4-aminobutyl) (meth)acrylamide hydrochloride, 4-azide Base-phenacylethylamine (meth)acrylamide, polyethylene glycol methyl ether acrylate (PEGMEA), polyethylene glycol diacrylate (PEGDEA) and RAFT reagent 2-(dodecyltrithio Carbonate group)-2-methylpropionic acid was added to the N,N-dimethylformamide solution with a concentration of 0.012M of the initiator 2,2'-azobis(2-methylpropionitrile). Among them, the degree of polymerization of ethylene glycol in PEGMEA is 5, the degree of polymerization of ethylene glycol in PEGDEA is 8, 2,2'-azobis(2-methylpropionitrile), RAFT reagent and all monomers participating in polymerization The molar ratio of the first reaction mixture is 1:2:100. 2,3-Dihydroxybenzoylbenzoate amine ethyl(meth)acrylamide hydrochloride: N-(4-aminobutyl) (Meth)acrylamide hydrochloride: 4-azido-phenacylethylam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com