Thermosensitive three-stage color-changing medical antipyretic patch and preparation method thereof

A heat-reducing sticker and heat-sensitive technology, applied in the field of medical devices, can solve problems such as inability to effectively highlight low-grade and high-grade fever, difficult preservation of heat-sensitive materials, changes in physical and chemical properties, etc. The effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

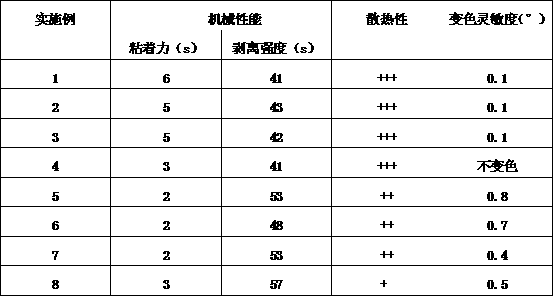

Examples

Embodiment 1

[0028] A heat-sensitive three-level color-changing medical antipyretic patch, including a spunlace non-woven fabric base cloth, a heat-sensitive hydrogel layer and a PP isolation film, the heat-sensitive hydrogel is coated on the spunlace non-woven fabric base fabric, and then laminated The PP isolation film can be obtained; among them, the heat-sensitive hydrogel layer directly contacts the human skin, absorbs the heat of the human body in the colloid, and then quickly evaporates the large amount of water stored in the hydrogel to take away the heat in the body, thereby reducing the temperature effect;

[0029] A preparation method of heat-sensitive three-stage color-changing medical antipyretic patch:

[0030] 1) By weight, weigh 0.5 part of the mixture of crystal violet lactone, fatty alcohol, and hydrated cobalt salt in a weight ratio of 0.5:4:1, and myristic acid, palmitic acid, and stearic acid in a weight ratio of 1:1: 1 part of the mixture of 2.5, 10 parts of polyviny...

Embodiment 2

[0033] A preparation method of heat-sensitive three-stage color-changing medical antipyretic patch:

[0034]1) By weight, weigh 0.3 parts of a mixture of crystal violet lactone, fatty alcohol, and hydrated cobalt salt in a weight ratio of 0.1:5:0.5, myristic acid, palmitic acid, and stearic acid in a weight ratio of 1:1: 1.6 parts of the mixture of 2.5, 3 parts of polyvinyl alcohol, dissolved in anhydrous alcohol, heated to 80°C and stirred continuously to allow it to react for 20 minutes, cooled with water to below 30°C, crystallized for 2 hours, suction filtered, and the filter residue was collected. Standby; mix and dissolve 10 parts of styrene, 3 parts of hydroxyethylacrylamide, and 0.5 parts of polyoxyethylene sorbitan monolaurate in water, stir at 45°C for 40 minutes to emulsify, and then add azobisisobutyl 0.1 part of amidine hydrochloride, heated to 80°C under stirring conditions, added the above filter residue at a rate of 0.5g / min, kept warm for 2 hours, then cooled ...

Embodiment 3

[0038] A preparation method of heat-sensitive three-stage color-changing medical antipyretic patch:

[0039] 1) By weight, weigh 0.8 parts of a mixture of crystal violet lactone, fatty alcohol, and hydrated cobalt salt in a weight ratio of 1:3:2, and myristic acid, palmitic acid, and stearic acid in a weight ratio of 1:1: 0.3 parts of the mixture of 2.5, 15 parts of polyvinyl alcohol, dissolved in anhydrous alcohol, heated to 70°C and stirred continuously to allow it to react for 20 minutes, cooled with water to below 30°C, crystallized for 1 hour, suction filtered, and the filter residue was collected. Standby; 1 part of styrene, 1 part of a mixture of divinylbenzene and methylol acrylamide, polyoxyethylene sorbitan monopalmitate, polyoxyethylene sorbitan monostearate, polyoxyethylene sorbitol Mix and dissolve 0.1 part of anhydride monooleate mixture in water, stir at 40-55°C for 40 minutes to emulsify, then add azobisisobutylamidine hydrochloride, azobisisobutylimidazoline h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com