Lithium metal anode material based on tio2 nanotube array/titanium foam and preparation method thereof

A technology of nanotube array and lithium metal negative electrode, which is applied to battery electrodes, electrical components, circuits, etc., to achieve the effects of simple process, uniform electric field distribution, and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

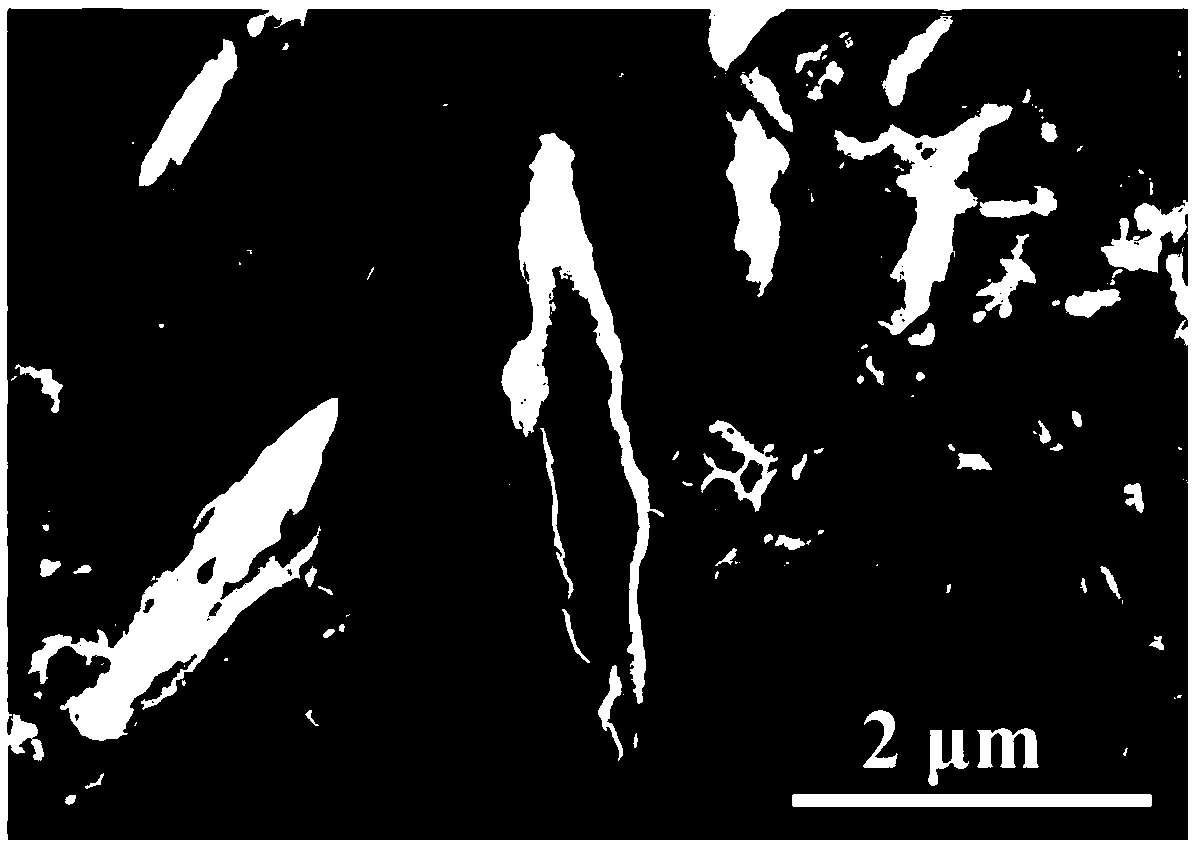

[0025] Preparation of TiO on the Surface of Porous Titanium Foam by Electrochemical Anodic Oxidation 2 Nanotube arrays, and crystallization annealing, and then using the melt infusion method, metal lithium and TiO 2 The nanotube array / titanium foam composite obtains a high metal lithium loading capacity, which can greatly limit the volume expansion of metal lithium and inhibit the production of metal lithium dendrites and "dead lithium" during the cycle charge and discharge process. Concrete preparation method steps are as follows:

[0026] 1. The titanium foam with a thickness of 0.5 mm and a pore size of 50 μm was cut to the required size.

[0027] 2. Ultrasonic cleaning of the cut foam titanium sheet in acetone, absolute ethanol and deionized water for 20 min respectively, and drying for use; prepare NH 4 F concentration is 0.25mol L -1 、H 2 8 % NH by volume of O 4 F—Water-ethylene glycol solution was used as the electrolyte, the cleaned foamed titanium sheet was use...

Embodiment 2

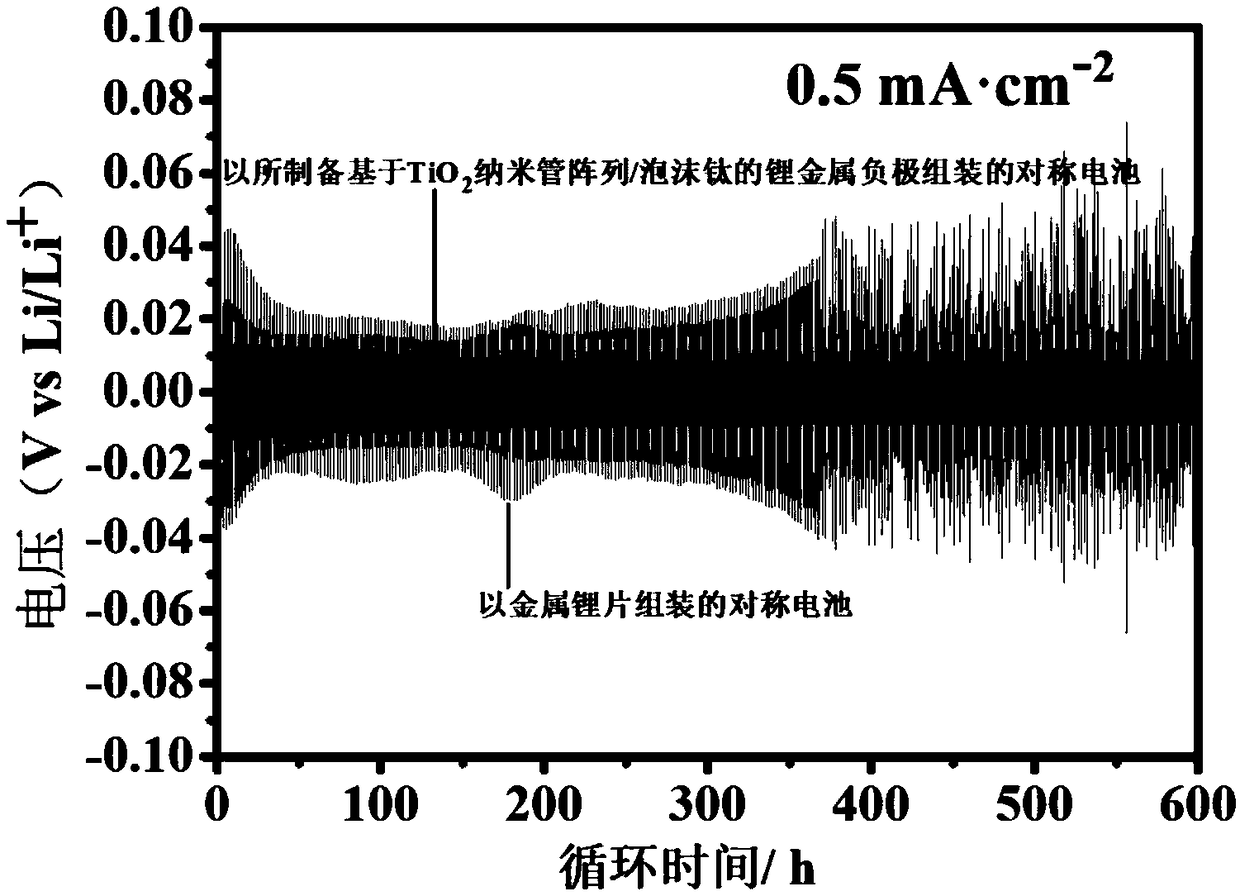

[0035] The preparation method of this embodiment is the same as that of embodiment 1, and the difference is that step 3 is skipped, that is, in step 4, the amorphous TiO 2 Nanotube array / titanium foam matrix immersed in molten lithium, allowing liquid molten lithium to absorb TiO 2 Nanotube array / titanium foam three-dimensional framework, other conditions remain unchanged, prepared based on TiO 2 Li metal anode material of nanotube array / titanium foam (amorphous TiO 2 ). Based on the TiO obtained in Example 1 2 Compared with the lithium metal anode material of nanotube array / titanium foam, the TiO-based 2 Li metal anode material of nanotube array / titanium foam (amorphous TiO 2 ) metal lithium loading decreased to 53.2wt.%, the hysteresis voltage of the assembled symmetric battery increased, and the cycle charge and discharge to 269 cycles (538 hours) failed.

Embodiment 3

[0037] The preparation method of this example is the same as that of Example 1, except that the titanium foam used in step 1 has a thickness of 0.5 mm, a pore size of 20 μm, and other conditional parameters remain unchanged. Based on the TiO obtained in Example 1 2 Compared with the lithium metal anode material of nanotube array / titanium foam, the TiO-based 2 The metal lithium loading of the lithium metal anode material of the nanotube array / titanium foam decreased to 47.3wt.%, and the hysteresis voltage of the assembled symmetrical battery increased slightly, and the cycle charge and discharge failed to 278 cycles (556 hours).

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Tube wall thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com