A mechanochemical polymerization method for preparing graphene/metal oxide composite electrode materials

A mechanochemical method and in-situ preparation technology, which is applied in the field of mechanochemical in-situ preparation of graphene/metal oxide composite electrode materials, can solve problems such as high efficiency and large-scale preparation of unfavorable composite energy storage electrode materials, and achieve high yield High, simple process, high synthesis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

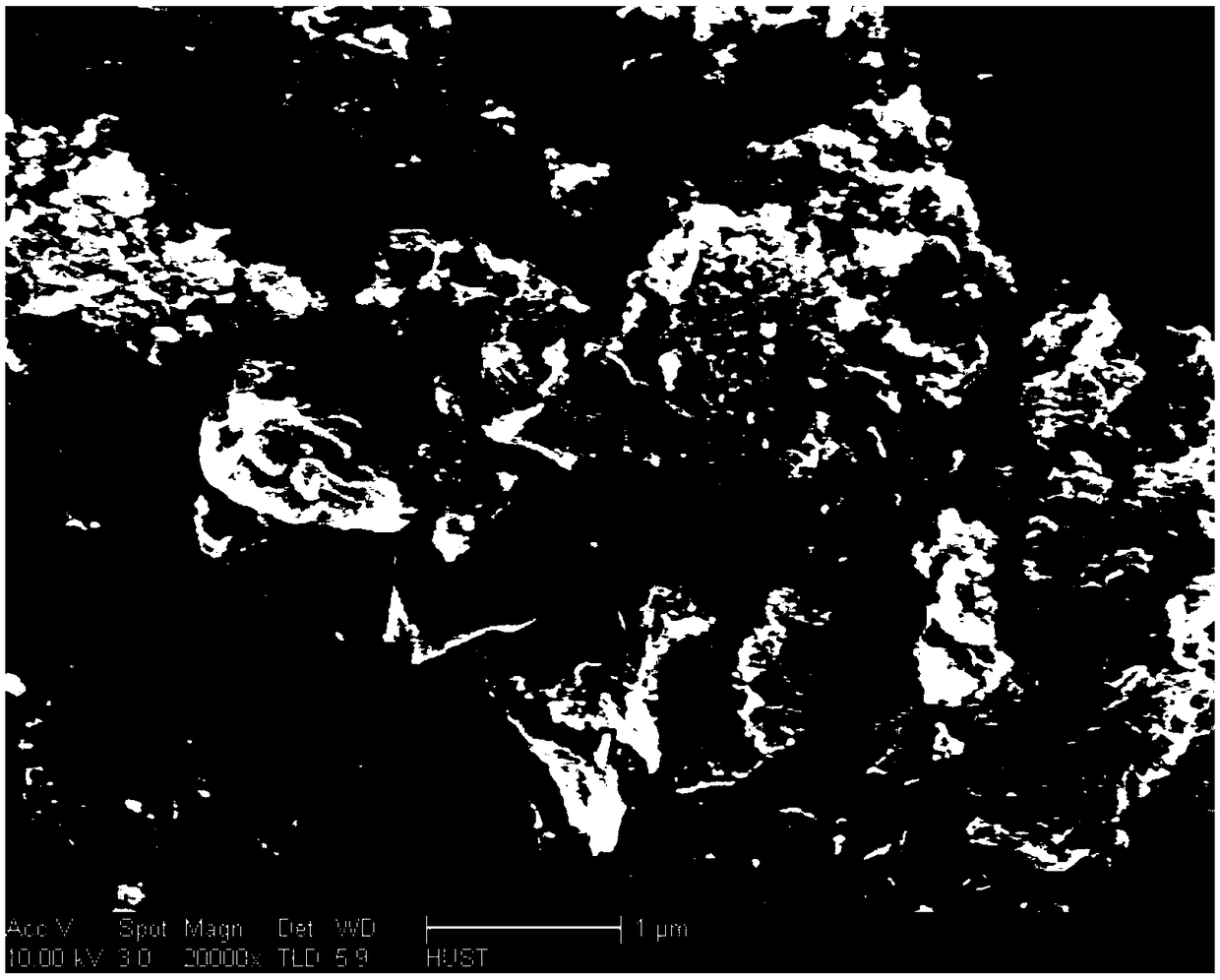

[0022] In the first example, the graphene / manganese dioxide composite electrode material was prepared by mechanochemical polymerization.

[0023] Preparation:

[0024] (1) Take 0.2 g of 100-mesh flake graphite and 1.58 g of potassium permanganate, add it to 50 mL of deionized water, mix evenly, and sonicate for 10 min, as liquid A.

[0025] (2) Add 2.27g of manganese sulfate and 0.5g of Tween 80 into 50mL of aqueous solution, stir for 30min, and use it as liquid B.

[0026] (3) Mix liquid A and liquid B evenly, and process it with a sand mill for 6 hours at a rotational speed of 2000 rpm to obtain mixture C.

[0027] (4) The mixture C was repeatedly washed with deionized water, filtered, washed with ethanol, filtered, and then vacuum-dried at 80° C. for 24 hours to obtain a graphene / manganese dioxide composite electrode material.

[0028] In this embodiment one, potassium permanganate and manganese sulfate are used as ion intercalation agents to promote graphite exfoliation ...

Embodiment 2

[0033] In the second embodiment, the graphene / cobalt tetroxide composite electrode material is prepared by mechanochemical polymerization, which specifically includes the following steps:

[0034](1) Take 0.25g of 80-mesh artificial graphite and 2.91g of cobalt nitrate hexahydrate, add it to 50mL of ethanol aqueous solution (volume ratio 1:1), mix evenly, and sonicate for 10min as liquid A.

[0035] (2) Take 8g of ammonium bicarbonate and 2.5g of polyoxyethylene ether, add it to 50mL of ethanol aqueous solution (volume ratio 1:1), stir for 30min, and use it as liquid B.

[0036] (3) Mix liquid A and liquid B evenly, and process it with a high-speed shear disperser for 2 hours at a rotation speed of 20,000 rpm, and control the reaction temperature to <50°C to obtain mixture C.

[0037] (4) The mixture C was repeatedly washed with ionized water and ethanol, filtered, and then vacuum-dried at 60° C. for 12 h to obtain complex D.

[0038] (5) The composite D was transferred to a ...

Embodiment 3

[0040] In this embodiment three, prepare graphene / NiCo by mechanochemical polymerization 2 o 4 Composite electrode material The composite electrode material specifically comprises the following steps:

[0041] (1) Take 0.5 g of 325-mesh expanded graphite, 1.77 g of nickel acetate, and 3.54 g of cobalt acetate and mix them uniformly as solid mixture A.

[0042] (2) Add 1.2 g of sodium hydroxide to the solid mixture A, mix well, and use it as the solid mixture B.

[0043] (3) The solid mixture B was transferred to a ball mill and sealed, and the solid phase mechanical ball mill was reacted for 6 hours at a rotation speed of 300 rpm to obtain a solid mixture C.

[0044] (4) The solid mixture C was repeatedly washed with deionized water and ethanol, filtered, and then vacuum-dried at 60° C. for 12 hours to obtain complex D,

[0045] (5) Transfer compound D to a tube furnace and treat it in an air atmosphere at 350°C for 4h to obtain graphene / NiCo 2 o 4 Composite electrode mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com