Tower-type photothermal power generation high-temperature molten salt (640 DEG C) thermal absorber tube panel

A heat absorber tube panel and photothermal power generation technology, which is applied to solar collectors, components of solar collectors, solar collectors using working fluids, etc., can solve problems such as corrosion and reduce manufacturing difficulty , Guarantee the effect of strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

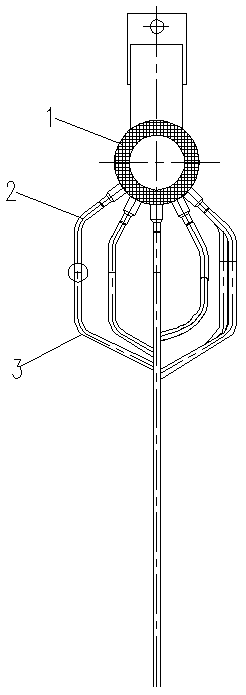

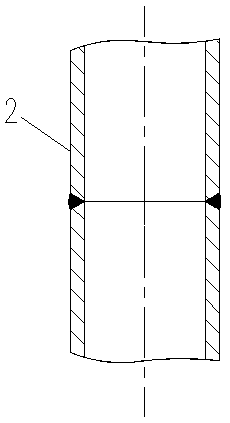

[0021] A tower-type photothermal power generation high-temperature molten salt (640°C) absorber tube panel, which consists of: header body 1, header pipe joint 2 and heat absorber tube panel 3, the header body and a The ends of the header pipe joints of the set are connected, and the other end of the header pipe joints is connected with the set of heat absorber tube panels, wherein the header pipe joints are connected with the The tube panel of the heat absorber is welded with a V-shaped groove.

Embodiment 2

[0023] According to the tube panel of the tower-type photothermal power generation high-temperature molten salt (640°C) absorber tube panel described in Example 1, the material of the header body is Sanicro25 large-diameter tube, and the material of the header pipe joint is Sanicro25 small-caliber tube The material of the tube panel of the heat absorber is Sanicro25, wherein the material of the Sanicro25 is austenite in the metallographic structure.

Embodiment 3

[0025] According to the tower-type photothermal power generation high-temperature molten salt (640°C) absorber tube panel described in embodiment 1 or 2, the yield strength of the Sanicro25 material is greater than or equal to 310MPa, the tensile strength is greater than or equal to 655MPa, and the elongation is greater than or equal to Equal to 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com