Lightweight insulation decorative external wall panel of rear bar planting anchoring foamed ceramics or foaming glass and preparation method thereof

A technology of foamed ceramics and foamed glass, applied in floors, coverings/linings, buildings, etc., can solve the problems of low cost performance, light weight, waterproof and anti-corrosion, aging resistance, and insufficient use of decorative materials. , achieve structural safety, significant economic and social benefits, and increase the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

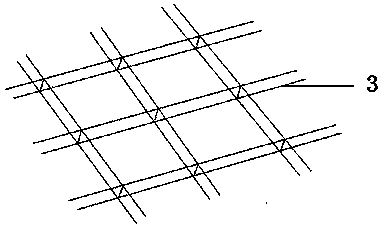

[0042] First set the bulk density to 400kg / m 3 The foamed pottery is cut into 20 small unit plates 1 with a thickness of 25cm × length 80cm × width 60cm. The structural diagram of the small unit plates 1 is as follows figure 1 shown. Place the above-mentioned unit plates horizontally on a steel platform, bond and cure the contact surface of the unit plates with polyurethane adhesive, and then open a groove 15 cm deep and 2 cm wide along the joints of the unit plates, clean the floating dust with a vacuum cleaner, and place a double-layer Φ12 The reinforced mesh sheet 3 of epoxy coating, the structural representation of reinforced mesh sheet 3 is as image 3 As shown, plug the side grooves around the side, pour self-leveling cement-based mortar binder 4, and place 160g / m on the surface 2 Alkali-resistant mesh cloth; soaked in cement-based mortar binder, the surface is smoothed, such as Figure 4 shown. After solidification, thick 5mm, wide 10cm steel strip hoop 5 is enclose...

Embodiment 2

[0044]First set the bulk density to 400kg / m 3 The foamed pottery is cut into 20 small unit plates with a thickness of 25cm × length 80cm × width 60cm. The small unit plates are cut 7mm around and 15cm in the thickness direction to form a stepped rectangular parallelepiped unit plate 2. Its structure diagram Such as figure 2 shown. Put the above-mentioned step-shaped cuboid with the big head down and the small head up on the steel platform horizontally, and assemble it into a wallboard shape of 320cm x 300cm x 25cm in thickness. The contact surface of the big cuboid is bonded and cured with epoxy resin adhesive. A groove with a depth of 15 cm and a width of 1.4 cm is formed on the head surface, and a double-layer Φ12 stainless steel steel mesh 3 is placed. The structural diagram of the steel mesh 3 is as follows image 3 As shown, plug the side grooves around the block, pour magnesium phosphate-based mortar binder, and place 200g / m2 on the surface 2 Basalt fiber mesh cloth ...

Embodiment 3

[0046] First set the bulk density to 600kg / m 3 The foamed pottery is cut into 50 unit plates with a thickness of 15cm×length 60cm×width 60cm, and the two pieces are stacked together, bonded and cured with an epoxy adhesive to form a small unit plate with a thickness of 30cm×length 60cm×width 60cm 25 pieces, the structural diagram of the unit plate is as follows figure 1 shown. Place the above-mentioned unit plates horizontally on a steel platform, bond and cure the contact surface of the unit plates with polyurethane adhesive to form a foamed ceramic plate with a length of 300cm×width 300cm×thickness 30cm, and then open a 20cm deep joint along the unit plate , 2cm wide groove, clean the floating dust with a vacuum cleaner, place Φ14 epoxy-coated steel mesh, seal the surrounding grooves, pour self-leveling cement-based mortar adhesive, and place 160g / m on the surface 2 Alkali-resistant mesh cloth, soaked in cement-based adhesive mortar, and the surface is smoothed. After sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com