FCC gasoline mercaptan etherification method

A technology of mercaptan ether and gasoline, applied in chemical instruments and methods, cracking, petroleum industry, etc., can solve the problems of difficult control of catalyst product quality, thioetherification catalyst not involved, catalyst composition and content, etc., to achieve octane The effect of low value loss, high catalyst activity and strong oil adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

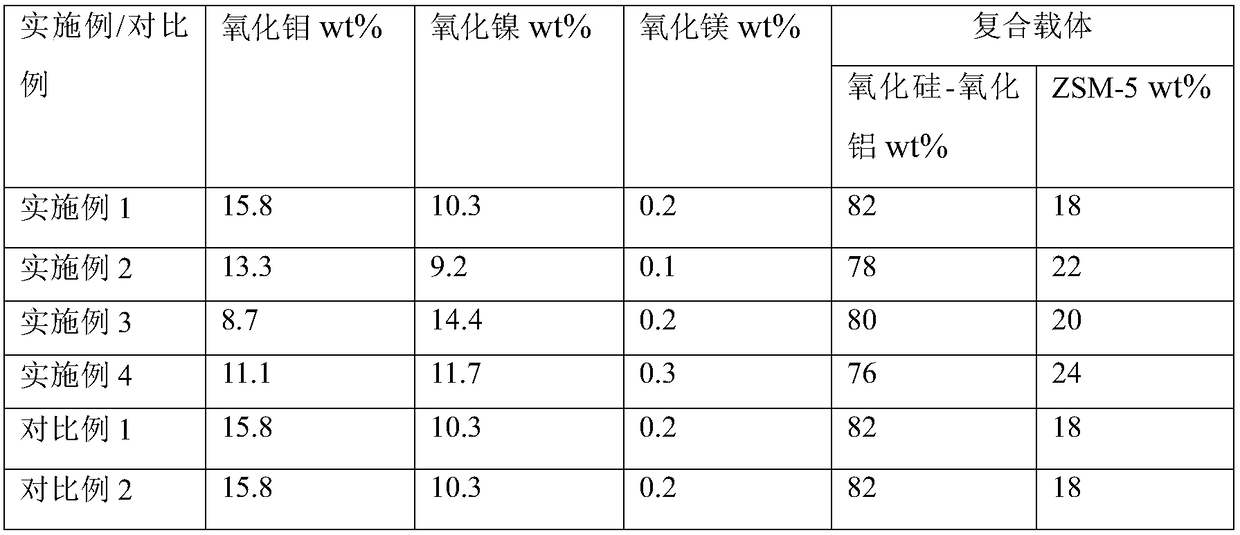

Examples

Embodiment 1

[0025] 1. Preparation of nickel-doped lanthanum ferrite

[0026] Under stirring conditions, dissolve 2.51mol lanthanum nitrate in 120mL water, add citric acid and stir to dissolve; then add 4.79mol iron nitrate, then add 190g sodium polyacrylate, then add 42g nickel nitrate aqueous solution, continue stirring for 30min, after drying Drying, roasting and grinding to obtain nickel-doped lanthanum ferrite.

[0027] 2. Preparation of silica-alumina carrier

[0028]Dissolve 5g of sodium polyacrylate in nitric acid, then add 38g of microsilica powder and 50g of pseudoboehmite powder, and stir evenly to obtain a mixture of microsilica powder-pseudoboehmite-sodium polyacrylate (abbreviated silicon-aluminum-organic mixture) , take 1 / 8 of the amount for later use, and add citric acid to 4.5g of nickel-doped lanthanum ferrite for later use. Add 300g of pseudo-boehmite powder and 25.0g of fenugreek powder into the kneader, add nitric acid, then add 40.2g of sodium polyacrylate nitric ac...

Embodiment 2

[0034] The preparation of nickel-doped lanthanum ferrite is the same as in Example 1, except that 260g of sodium polyacrylate is added, and the preparation of the silica-alumina carrier is the same as in Example 1. The silica-alumina carrier contains 4.4wt% of silicon oxide, 5.7wt% % nickel-doped lanthanum ferrite, 1.6wt% potassium, carrier mesopores accounted for 64.2% of the total pores, and macropores accounted for 25.6% of the total pores. The unit content of sodium polyacrylate in the alumina precursor is 3 times higher than the content of sodium polyacrylate in the silicon source-organic polymer mixture. The preparation of the composite carrier is the same as in Example 1, and the preparation method of catalyst 2 is the same as in Example 1.

Embodiment 3

[0036] The preparation of nickel-doped lanthanum ferrite is the same as in Example 1, except that 220g of polyacrylic acid is added, and the preparation of the silica-alumina carrier is the same as in Example 1. The silica-alumina carrier contains 8.4wt% of silicon oxide, 2.6wt% Nickel-doped lanthanum ferrite, 0.8wt% potassium, the carrier mesopores account for 54.6% of the total pores, and the macropores account for 33.5% of the total pores. The unit content of polyacrylic acid in the alumina precursor is 3.3 times higher than that in the silicon source-organic polymer mixture. The preparation of the composite carrier is the same as in Example 1, and the preparation method of catalyst 3 is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com