Nano silica-modified waterborne polyurethane emulsion, and preparation method and use thereof

A nano-silica, water-based polyurethane technology, applied in polyurea/polyurethane coatings, coatings, fireproof coatings, etc., can solve the problems of triethylamine volatilization, poor friction resistance, insufficient hardness, etc., and achieve high temperature resistance, transparency, Excellent peelability, effect of solving triethylamine VOC problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

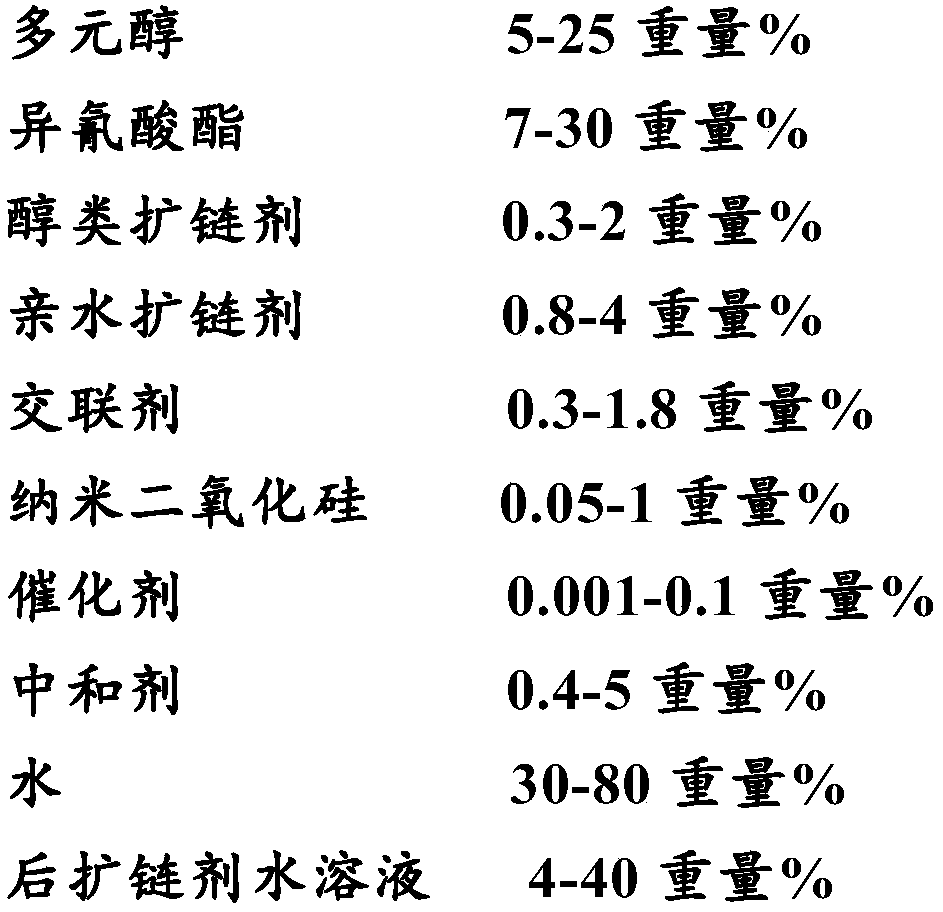

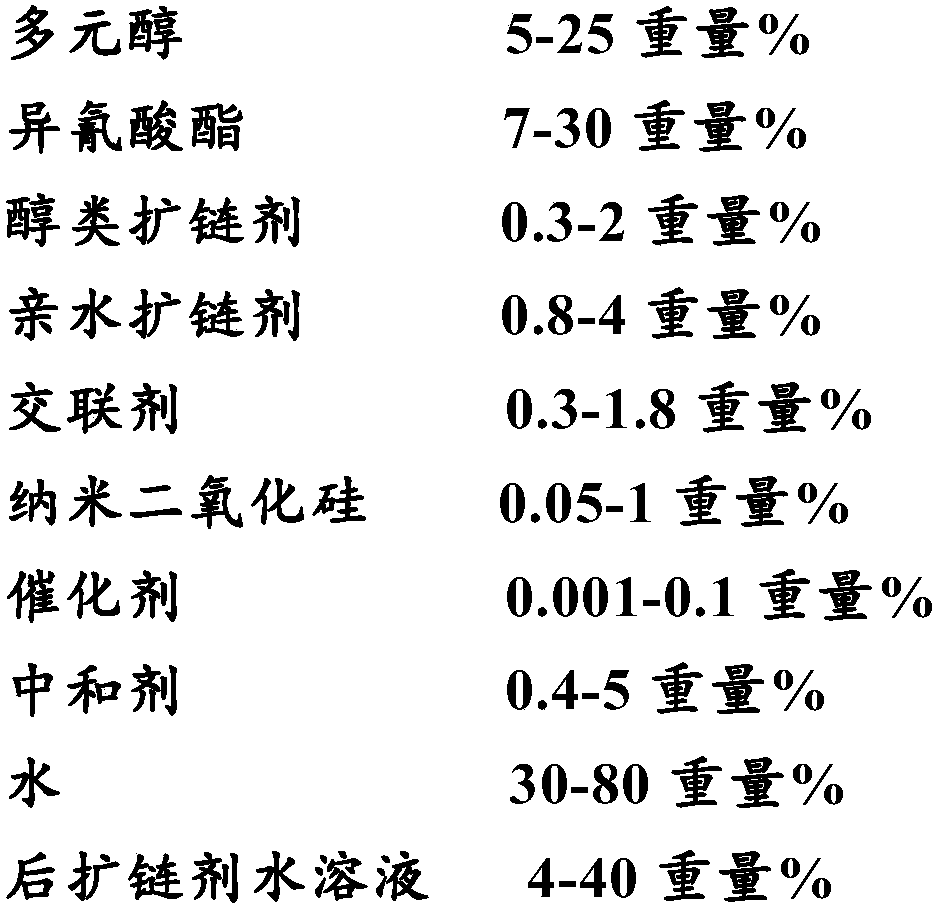

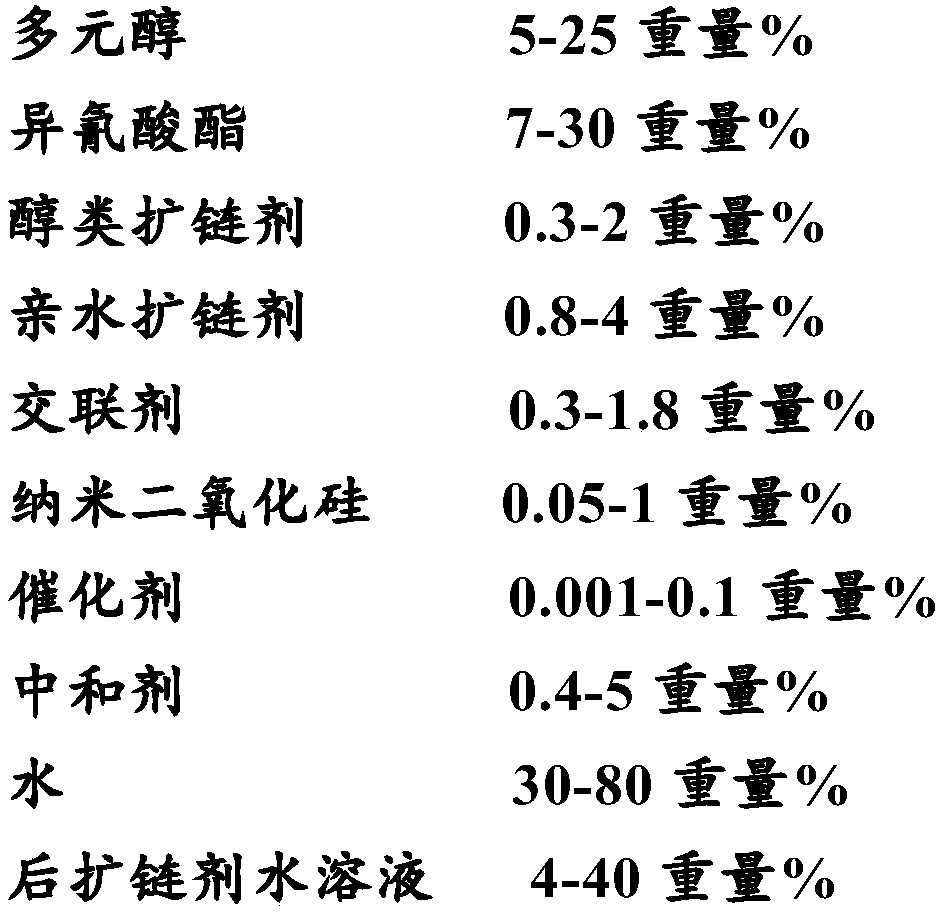

Method used

Image

Examples

Embodiment 1

[0067]200g of polyester polyol CMA-1044 (M based on 1,4-butanediol-adipic acid n =1000, OH value=106-118mgKOH / g, Huada Chemical Group) was placed in a vacuum oven (model YZF6250, manufacturer: Shanghai Yaoshi Instrument Equipment Factory) at 120°C and dried for 1.5 hours to remove moisture in CMA-1044; Reduce its moisture content to 0.1% by weight, wherein the determination of moisture is carried out according to the Karl Fischer method in GB / T 11275-2007;

[0068] Add 80g of dried CMA-1044 into a 1000ml four-neck flask, then add 88g of isophorone diisocyanate (purchased from Bayer, Germany), and react at 85°C for 2.5h to obtain a polyurethane prepolymer. Then keep the temperature at 70°C, first add 5g of 1,4-butanediol, react for 0.5 hours; then add 9g of dimethylolpropionic acid, react for 0.5 hours, add 40ml of methyl ethyl ketone to adjust the viscosity of the prepolymer; After adding 0.09g of dibutyltin dilaurate catalyst, 4g of trimethylolpropane and 1.5g of nano silica...

Embodiment 2

[0072] 200g polytetrahydrofuran ether glycol (PTMG)-1000 (M n =1000, OH value=107-117mgKOH / g, purchased from Mitsubishi Chemical Co., Ltd. of Japan) and dried in a vacuum oven (model YZF6250, manufacturer: Shanghai Yaoshi Instrument Equipment Factory) at 120°C for 1.5 hours to remove PTMG-1000 Moisture; reduce its moisture content to 0.1% by weight, wherein the determination of moisture is carried out according to the Karl Fischer method in GB / T 11275-2007;

[0073] Add 70g of dried PTMG-1000 into a 1000ml four-neck flask, then add 85g of 4,4-dicyclohexylmethane diisocyanate (purchased from Bayer, Germany), and react at 87°C for 2.5h to obtain a polyurethane prepolymer . Then keep the temperature at 70°C, first add 4g of 1,4-butanediol, react for 0.5 hours; then add 12g of dimethylolpropionic acid, react for 0.5 hours, add 30ml of methyl ethyl ketone to adjust the viscosity of the prepolymer; Then add 0.1g of dibutyltin dilaurate catalyst, 5g of trimethylolpropane and 2g of ...

Embodiment 3

[0077] 200g of polyester polyol CMA44-600 (M based on 1,4-butanediol-adipic acid n =600, OH value=185-205mg KOH / g, Huada Chemical Group) was placed in a vacuum oven (model YZF6250, manufacturer: Shanghai Yaoshi Instrument Equipment Factory) at 120°C and dried for 1.5 hours to remove moisture in the CMA44-600 ; Reduce its moisture content to 0.1% by weight, wherein the determination of moisture is carried out according to the Karl Fischer method in GB / T 11275-2007;

[0078] Add 50g of dried CMA44-600 into a 1000ml four-neck flask, then add 70g of hexamethylene diisocyanate (purchased from Wanhua Chemical Group), and react at 85°C for 2.5h to obtain a polyurethane prepolymer. Then keep the temperature at 70°C, first add 4g of 1,4-butanediol, react for 0.5 hours; then add 9g of dimethylol formic acid, react for 0.5 hours, add 25ml of methyl ethyl ketone to adjust the viscosity of the prepolymer; Add 0.12g of stannous octoate catalyst, 4g of trimethylolpropane and 1g of nano-sili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com