Resistance copper slurry and preparation method thereof

A technology of resistance and copper paste, which is applied in the direction of electrical components, printed circuits, printed circuit parts, etc., can solve the problems of complex fixed resistance components, complex production process of components, long curing time of paste, etc., and achieve production cost Low, short curing time, high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

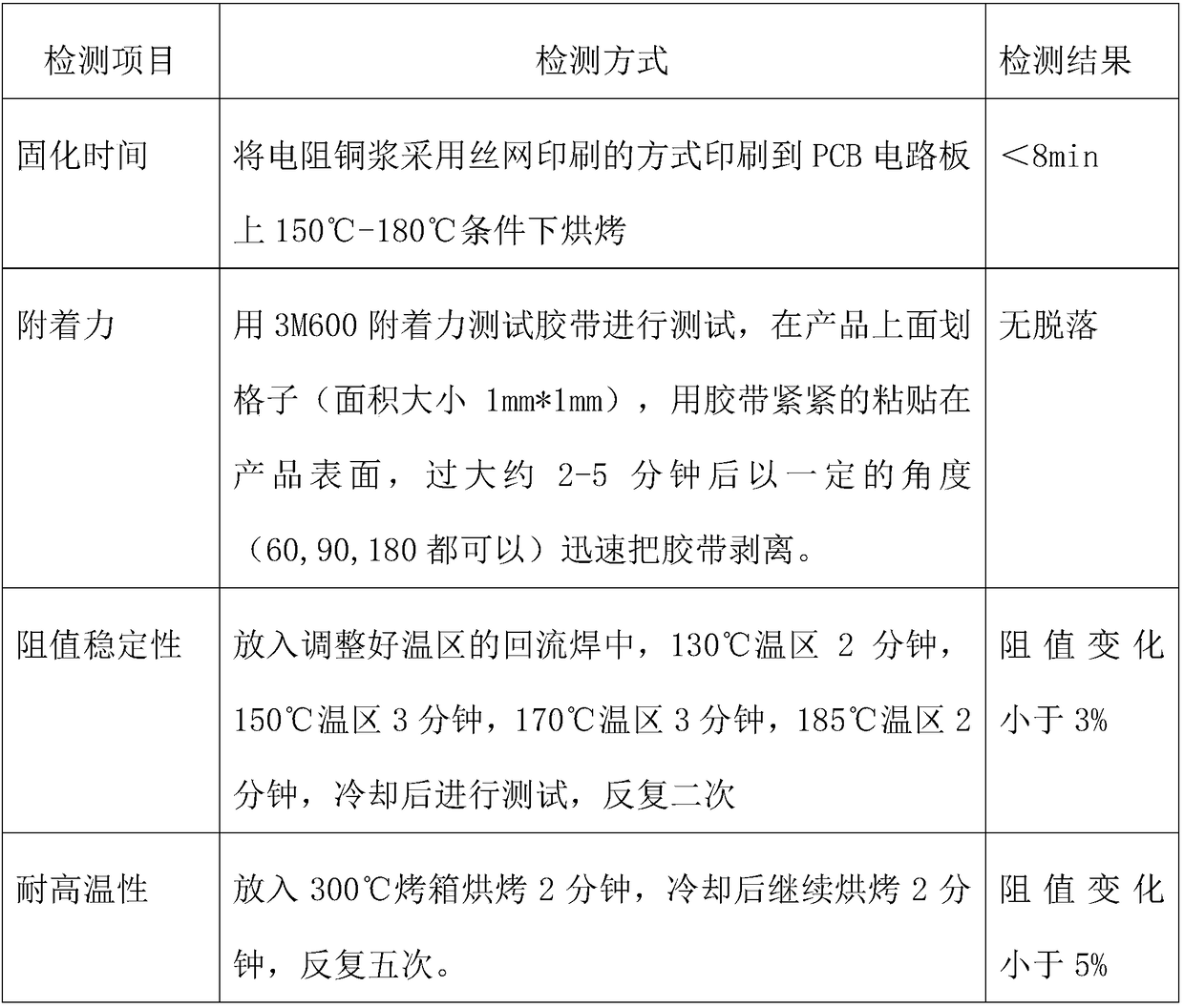

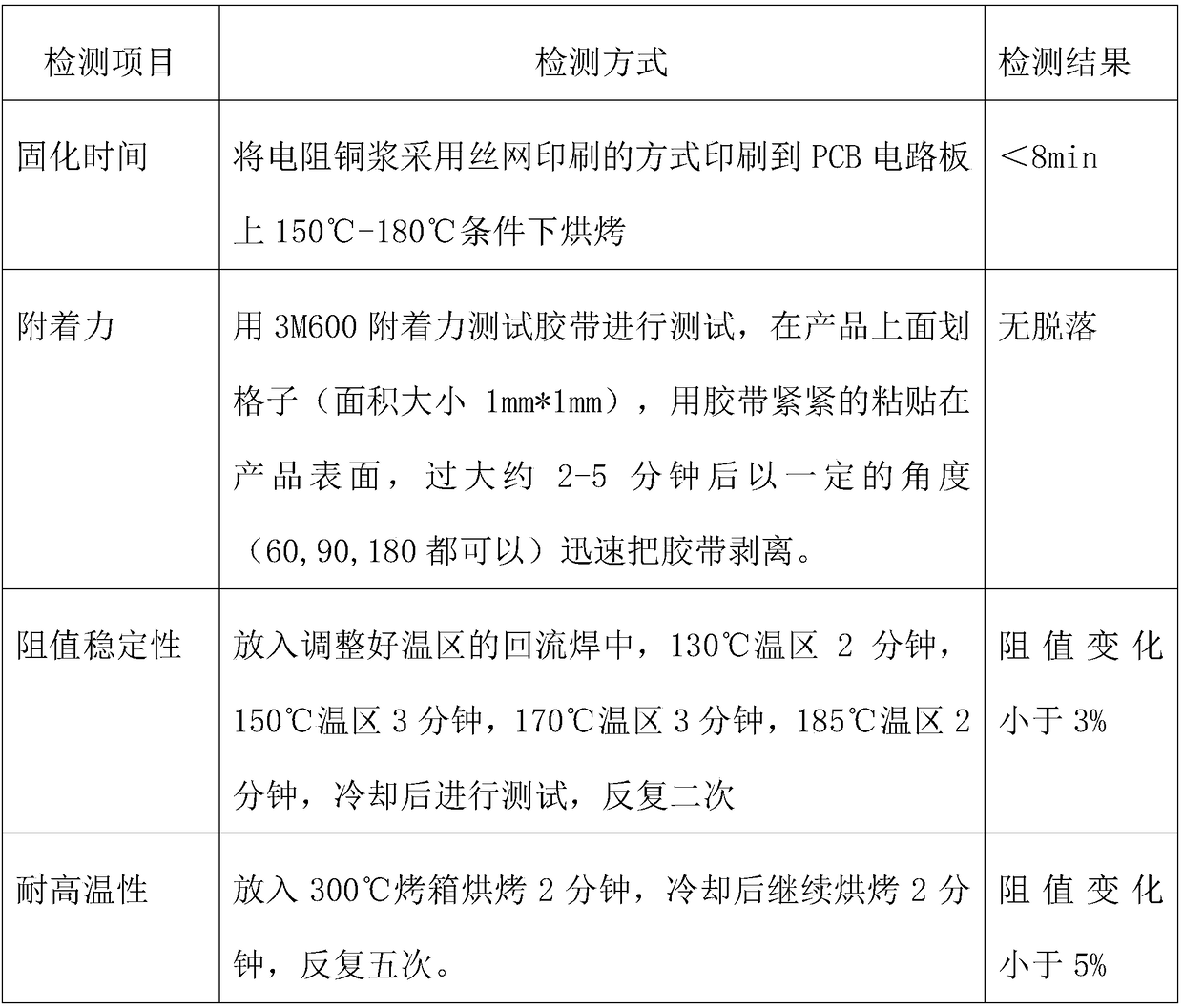

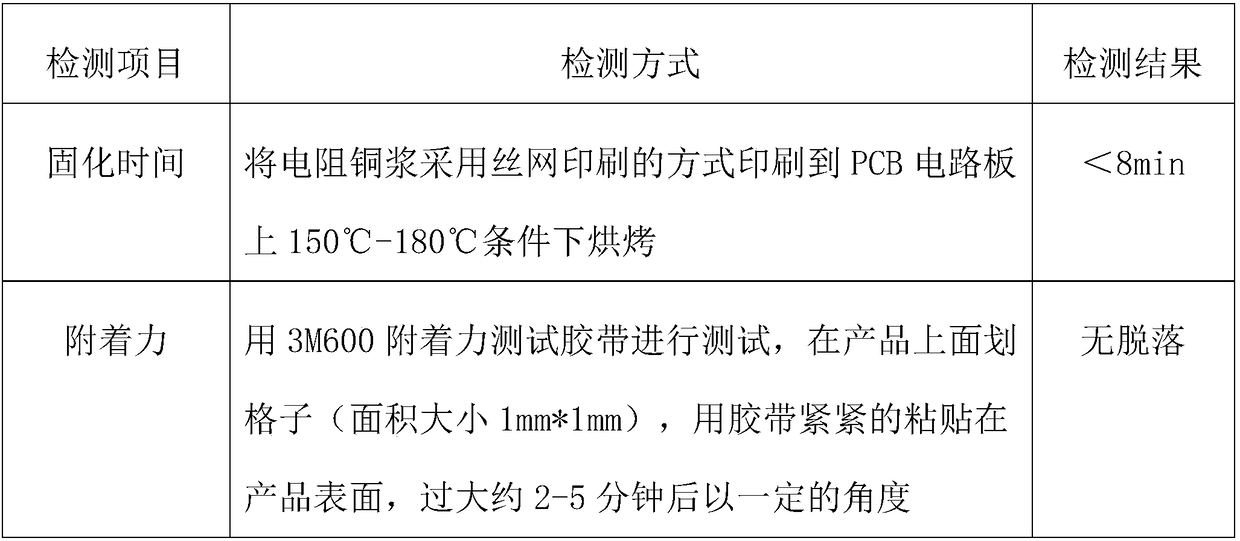

Image

Examples

Embodiment 1

[0036] Embodiment 1 of the present invention provides a resistance copper paste, which is mainly made of the following components in proportion by weight: 14 parts of trimethylolpropane triacrylate, 26 parts of N-vinylpyrrolidone, 5 parts of dibasic acid ester 40 parts, 40 parts of epoxy acrylic resin, 3 parts of fatty alcohol polyoxyethylene ether, 2 parts of sodium dodecylbenzenesulfonate, 10 parts of tert-butyl peroxybenzoate and 90 parts of silver-coated copper powder.

[0037] The preparation method of the resistance copper paste of the present embodiment is as follows:

[0038] Under normal temperature and pressure, trimethylolpropane triacrylate and N-vinylpyrrolidone were mixed together and stirred together for about five minutes according to the weight parts of the above ratio, so that they were fully mixed to obtain mixture A; Add the divalent acid ester to the mixture A and stir for about five minutes to ensure that the divalent acid ester and the mixture A are full...

Embodiment 2

[0044] Embodiment 2 of the present invention provides a resistance copper paste, which is mainly made of the following components in proportion by weight: 12 parts of trimethylolpropane triacrylate, 25 parts of N-vinylpyrrolidone, 3 parts of dibasic acid ester Parts, 38 parts of epoxy acrylic resin, 2 parts of fatty alcohol polyoxyethylene ether, 1 part of surfactant, 8 parts of initiator and 100 parts of silver-coated copper powder.

[0045] The preparation method of the resistance copper paste of the present embodiment is as follows:

[0046] Under normal temperature and pressure, trimethylolpropane triacrylate and N-vinylpyrrolidone were mixed together and stirred together for about five minutes according to the weight parts of the above ratio, so that they were fully mixed to obtain mixture A; Add the divalent acid ester to the mixture A and stir for about five minutes to ensure that the divalent acid ester and the mixture A are fully mixed to obtain the mixture B; then ad...

Embodiment 3

[0052] Embodiment 3 of the present invention provides a resistance copper paste, which is mainly made of the following components in proportion by weight: 16 parts of trimethylolpropane triacrylate, 28 parts of N-vinylpyrrolidone, 6 parts of dibasic acid ester parts, 45 parts of epoxy acrylic resin, 5 parts of fatty alcohol polyoxyethylene ether, 3 parts of surfactant, 13 parts of initiator and 80 parts of silver-coated copper powder.

[0053] The preparation method of the resistance copper paste of the present embodiment is as follows:

[0054]Under normal temperature and pressure, trimethylolpropane triacrylate and N-vinylpyrrolidone were mixed together and stirred together for about five minutes according to the weight parts of the above ratio, so that they were fully mixed to obtain mixture A; Add the divalent acid ester to the mixture A and stir for about five minutes to ensure that the divalent acid ester and the mixture A are fully mixed to obtain the mixture B; then ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com