Preparation method of ultraviolet light induced surface self-folding pattern and application of pattern in constructing anti-counterfeiting marks

An ultraviolet light and wrinkle technology, which is applied in the field of wrinkle patterns, can solve problems that do not involve intelligent identification of patterned surface anti-counterfeiting marks, and achieve the effects of repeated use, easy availability of raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

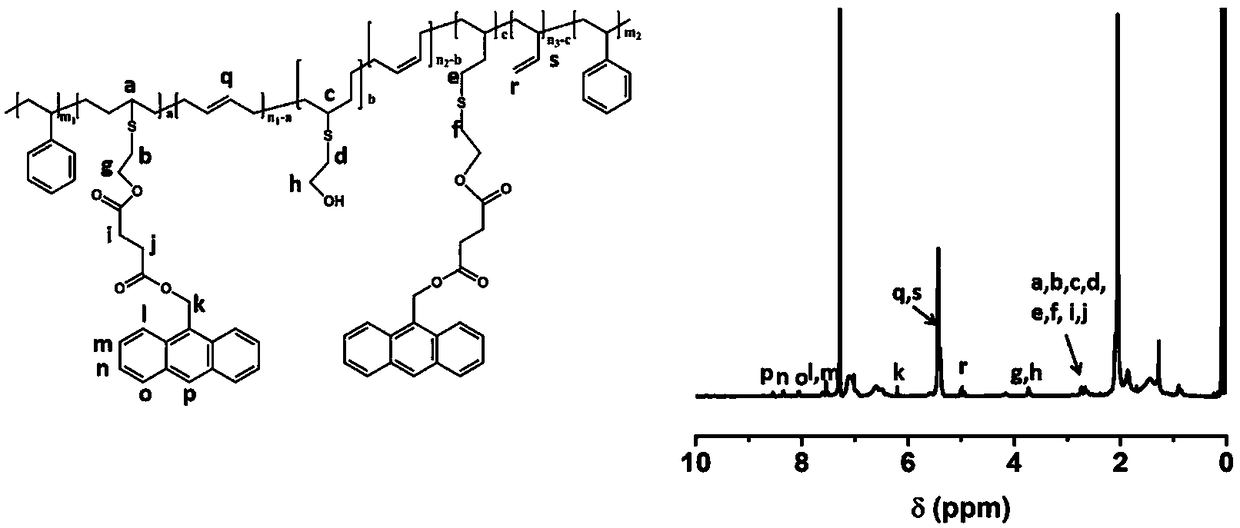

[0069] Dissolve SBS and mercaptoethanol in a solvent according to a certain ratio, add a photoinitiator, and carry out grafting reaction. In this example, the content of mercaptoethanol accounts for 30%, and the hydroxyl-grafted SBS is obtained. On this basis, a certain amount of anthracene carboxylic acid compound is added, and the anthracene group is grafted onto the hydroxyl-functionalized SBS molecular chain by esterification reaction. In this example, the mole fraction of the carboxyl group of the anthracene carboxylic acid compound relative to the hydroxyl group was 40%, and the anthracene-grafted SBS was prepared.

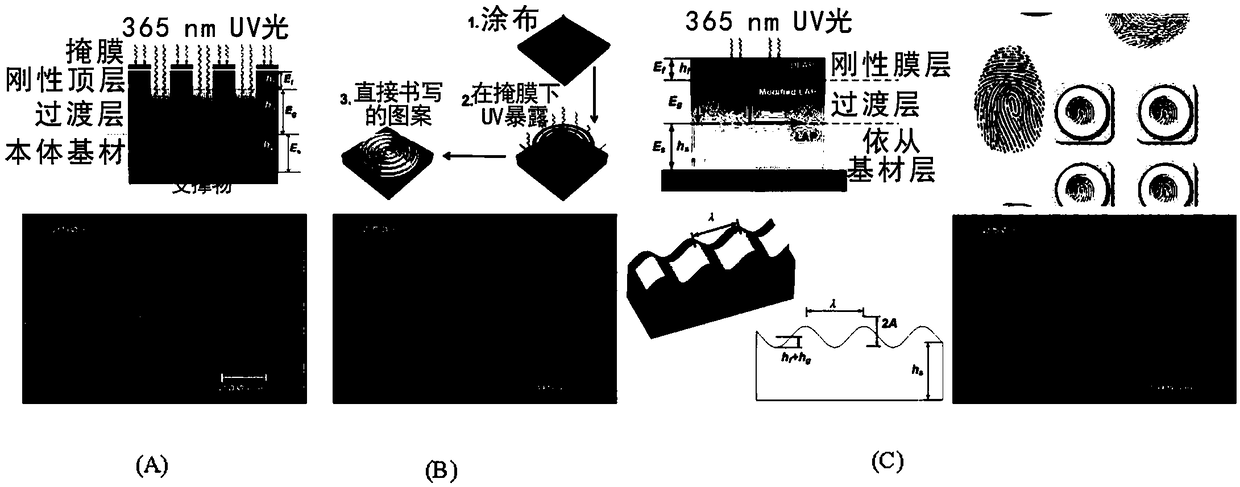

[0070] Anthracene-grafted SBS was dissolved in toluene, the concentration in this example was set at 25%, and after stirring evenly, it was drop-coated on a glass sheet, and dried to remove the solvent to obtain a single-layer uniform film. The film was placed under ultraviolet light for 10 minutes, and the surface formed a self-wrinkled structure. figure ...

Embodiment 2

[0072]Polybutadiene and mercaptoethanol are dissolved in a solvent according to a certain ratio, and a photoinitiator is added to carry out a click reaction. In this example, the content of mercaptoethanol accounts for 40% to obtain hydroxyl-grafted polybutadiene. On this basis, a certain amount of anthracene carboxylic acid compound is added, and the anthracene group is grafted onto the hydroxyl functionalized polybutadiene molecular chain by esterification reaction. In this example, the mole fraction of the carboxyl group of the anthracene carboxylic acid compound relative to the hydroxyl group was 30%, and anthracene-grafted polybutadiene was prepared.

[0073] Anthracene-grafted polybutadiene was dissolved in chloroform, the concentration in this example was set at 20%, after stirring evenly, it was dropped on a glass sheet, and the solvent was dried to obtain a single-layer uniform film. The film was placed under ultraviolet light with a wavelength of 365nm for 5 minutes,...

Embodiment 3

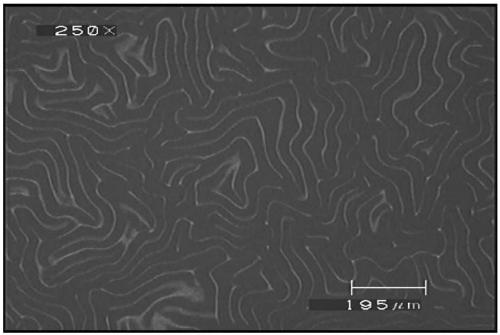

[0075] Polybutadiene (polybutadiene used in this example is commercially available BR9000) and photoinitiator are dissolved in xylene, and the concentration in this example is set as 15%, after stirring evenly, drop on the glass sheet, dry and remove solvent , to obtain a monolayer homogeneous film. Place the film under ultraviolet light with a wavelength of 254nm for 20 minutes, and the surface forms a self-wrinkled structure. Figure 6 It is the wrinkle pattern formed after the polybutadiene system is exposed to ultraviolet light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com