Production method of ultra pure electronic grade hydrochloric acid and isopropanol

A production method and electronic-grade technology, applied in chemical instruments and methods, halogen/halogen acid, chlorine/hydrogen chloride purification, etc., can solve the problems of complex equipment and limited purity, achieve steam saving, avoid high impurity content, improve Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

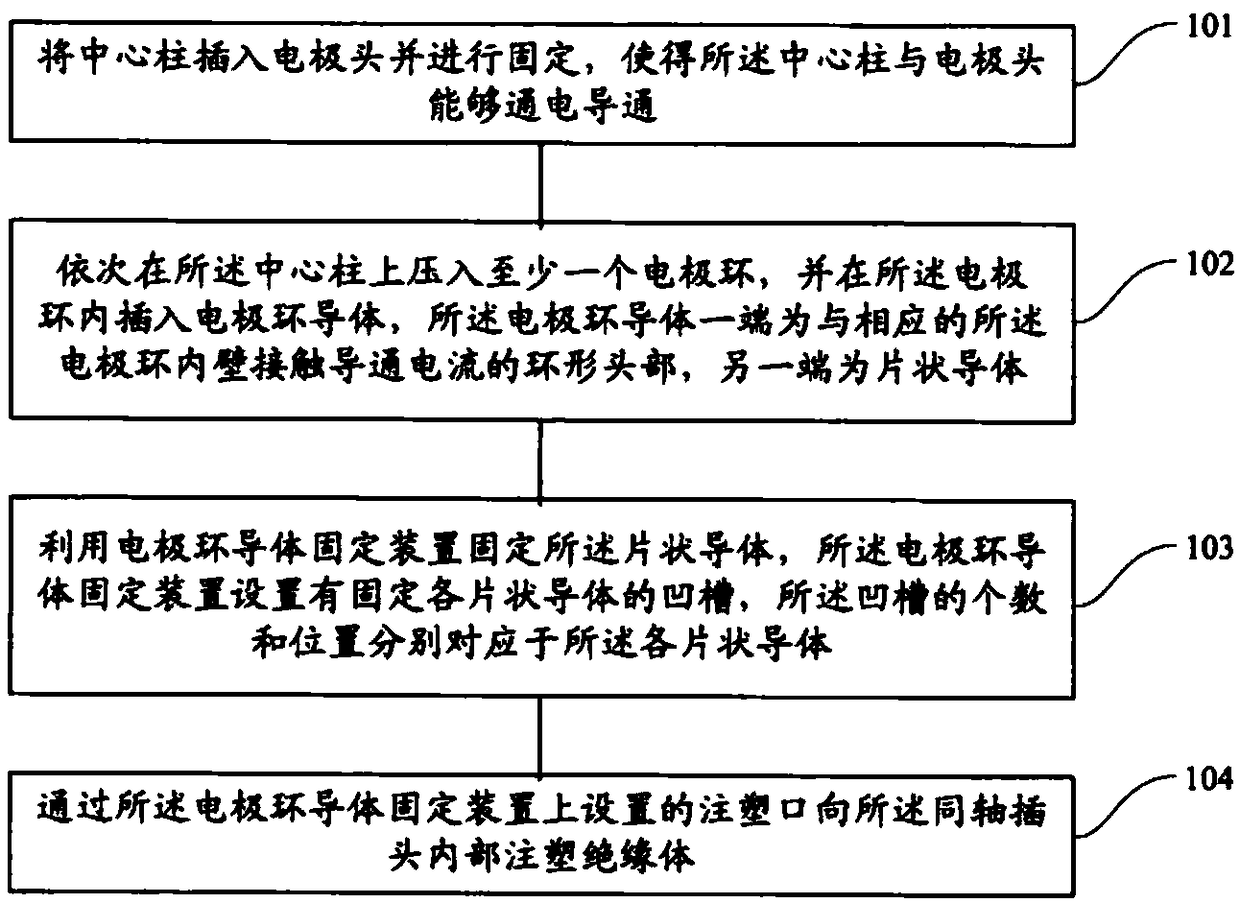

[0034] refer to figure 1 , taking the rectifying tower as an example, the preparation method of the ultrapure electronic grade chemical reagent of the present invention is specifically introduced as follows:

[0035] Step 1: At room temperature, input industrial grade hydrochloric acid or industrial grade isopropanol into the preprocessor through the industrial grade raw material tank, and pretreatment reagents such as dehydrating agent, dearsenic agent, oxidizing agent, reducing agent, etc. pass through the pretreatment reagent tank Enter the pre-processor to chemically pre-treat industrial-grade raw materials to remove major impurities to improve purity.

[0036] Filter and collect the filtrate.

[0037] Step 2: Transfer the filtrate to a rectification tower for rectification.

[0038] During rectification, the gas flow in the tower is controlled at 0.5-1.5 m / s.

[0039] A heater is installed in the rectification tower. During the rectification process, the steam is furth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com